Labeling machine

A labeling machine and equipment technology, applied in the direction of labeling machines, labels, labels, etc., can solve the problems affecting the quality of logo pasting, low quality of pasting logos, and high labor costs, so as to improve the quality of labeling and reduce labor Strength, the effect of reducing manpower waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

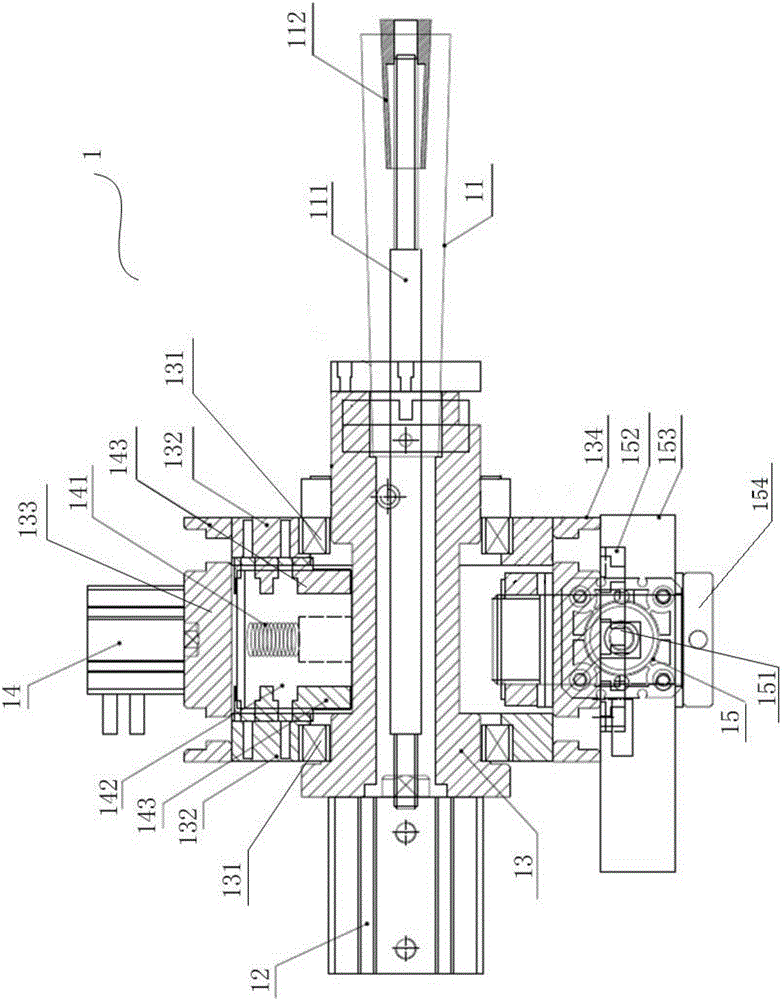

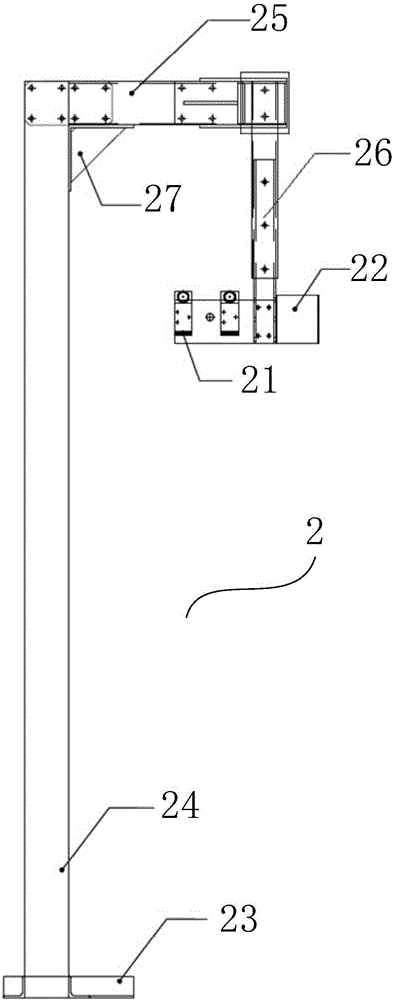

[0020] Such as figure 1 and figure 2 As shown, a kind of labeling machine equipment of this embodiment is used for labeling the vehicle frame, and includes a vehicle frame fixing device 1; The device box 11 is connected with the first driving device that drives it to open or close; the tensioning device box 11 is fixedly connected to the rotating main shaft 13 arranged along the X-axis direction, and the rotating main shaft 13 can rotate around the X-axis direction and around the Y-axis respectively direction rotation, the rotating main shaft 13 is respectively provided with a first brake device for stopping the rotation of the main shaft 13 around the X-axis direction, and a second braking device for stopping the rotation of the main shaft 13 around the Y-axis direction, and the first driving device , the first braking device and the second braking device are respectively connected to the manual solenoid valve 21 for control.

[0021] Wherein, the first driving device is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com