Bracket for vertical type steel reel packaging

A technology for packaging and steel coils, which is applied in the directions of packaging, transportation and packaging, and external frames. It can solve the problems that the ends are easy to touch the surface of the steel coil, the size cannot be adjusted, and the surface of the steel coil is damaged. It has a simple structure and is easy to use. The effect of long life and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

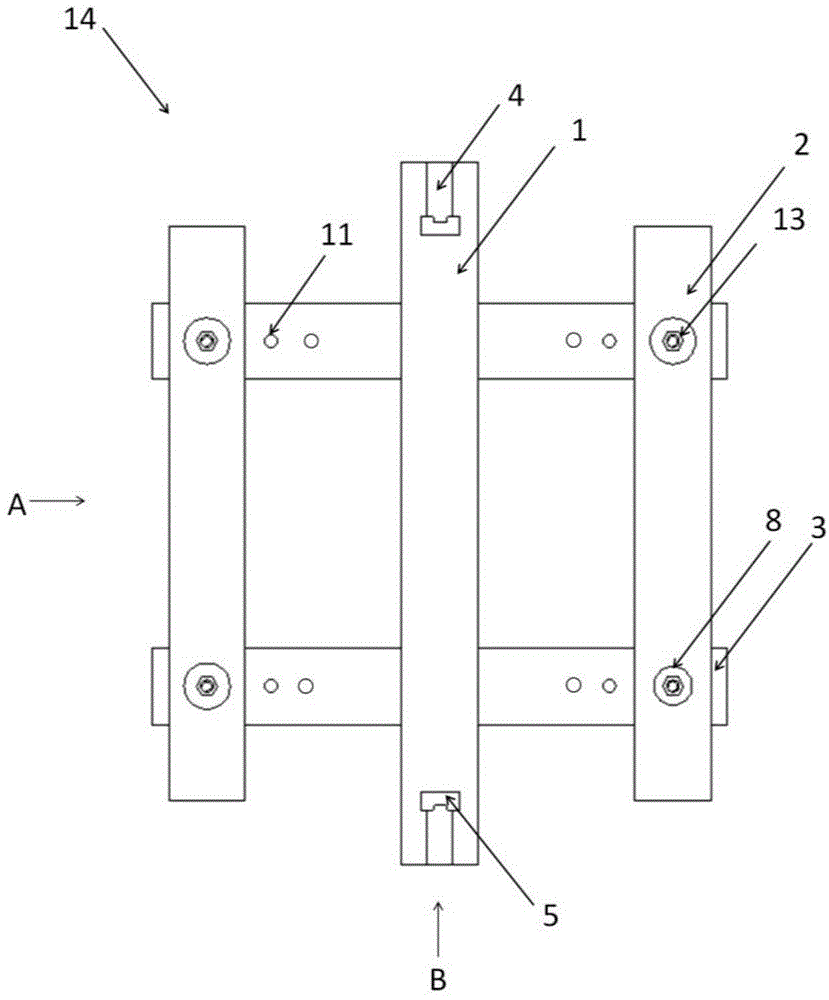

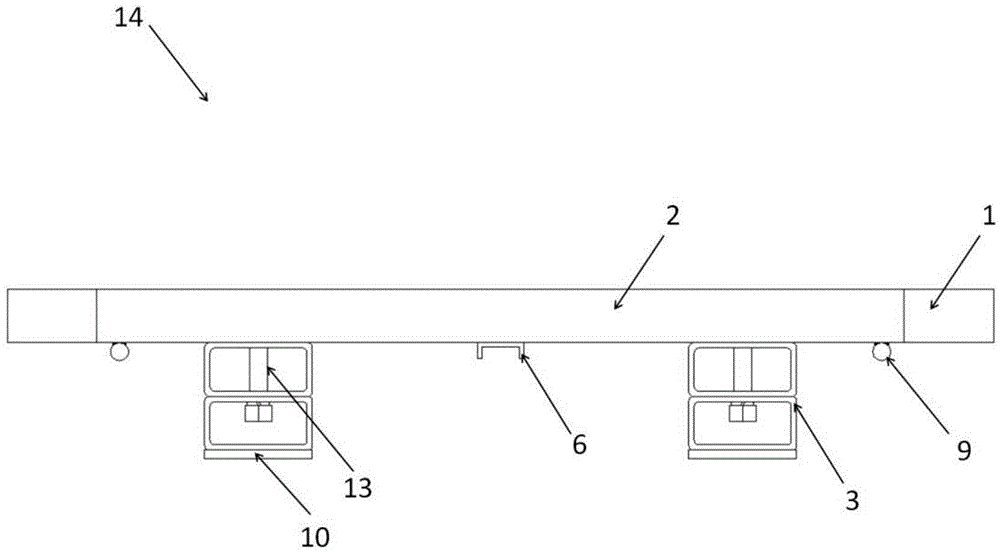

[0021] This embodiment provides a size-adjustable vertical steel coil packaging bracket, which is suitable for the occasion of packaging multiple steel coils with different outer diameters. The "upper" and "lower" mentioned in this embodiment only mean figure 2 and image 3 The relative position in , not limited to the position in real space. Such as figure 1 As shown, the bracket 14 for vertical steel coil packaging in this embodiment is made of steel material, including an upper structure and a lower structure.

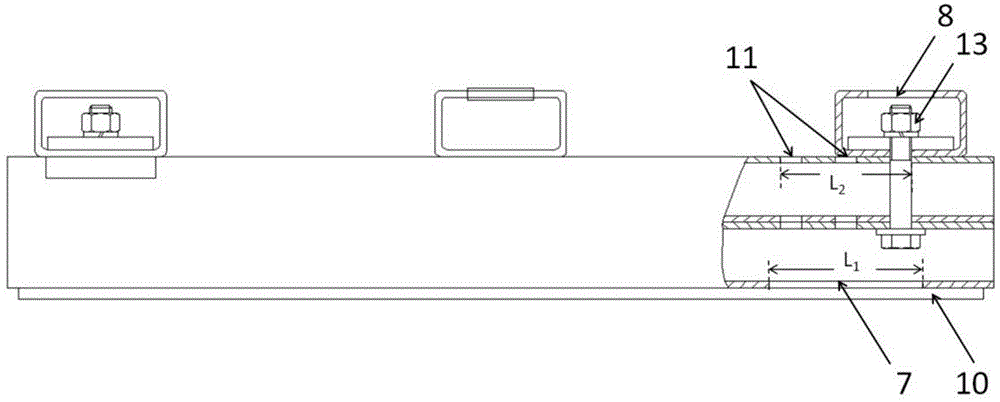

[0022] Such as figure 2 As shown, the substructure consists of two bottom beams 3 arranged in parallel. Each bottom beam 3 is welded by two hollow rectangular steel pipes, which is to ensure the bending strength. The bottom beam 3 is connected to the superstructure by bolts 13 .

[0023] Such as figure 1 As shown, the two ends of each bottom beam 3 are provided with three positioning holes 11 along its length direction. The three positioning holes 11 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com