Highway concrete formula and processing technology

A processing technology, concrete technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of reduced concrete fluidity, impact on concrete quality, slump loss, etc., to reduce water absorption , save laying costs, improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

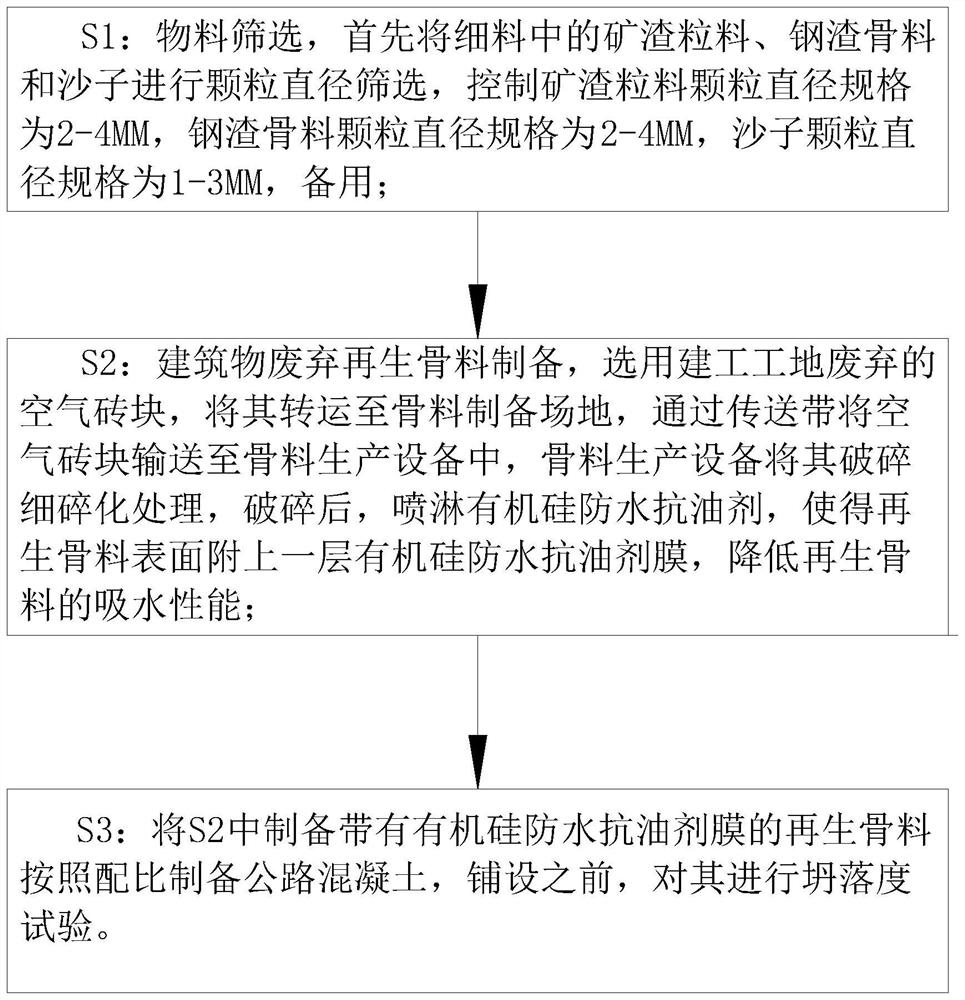

[0054] refer to Figure 1-7 , a highway concrete processing technology, the processing technology is used for processing the above-mentioned a kind of highway concrete formula, the processing technology comprises the following steps:

[0055] S1: Material screening, firstly screen the slag pellets, steel slag aggregate and sand in the fine material by particle diameter, control the diameter of slag pellets to be 2-4MM, the diameter of steel slag aggregate to be 2-4MM, and the size of sand particles to be 2-4MM. The diameter specification is 1-3MM, spare;

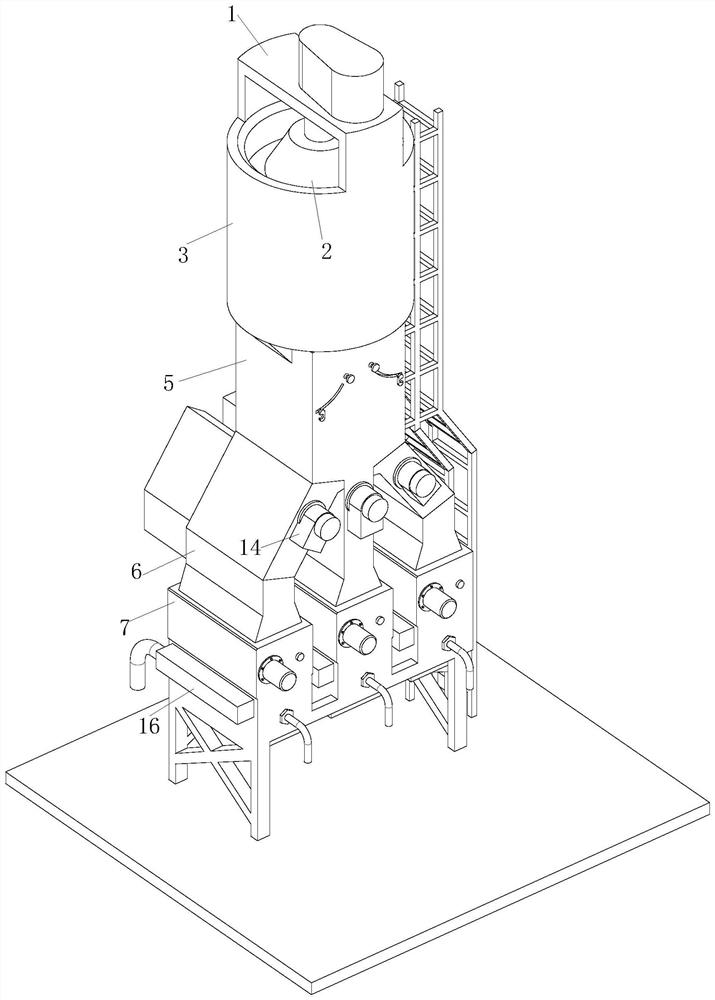

[0056] S2: Preparation of waste recycled aggregates in buildings. Select the air bricks discarded at the construction site, transfer them to the aggregate preparation site, and transport the air bricks to the aggregate production equipment 1 through the conveyor belt. The aggregate production equipment 1 will It is crushed and finely crushed. After crushing, the silicone waterproof and oil-repellent agent is sprayed, so tha...

Embodiment 2

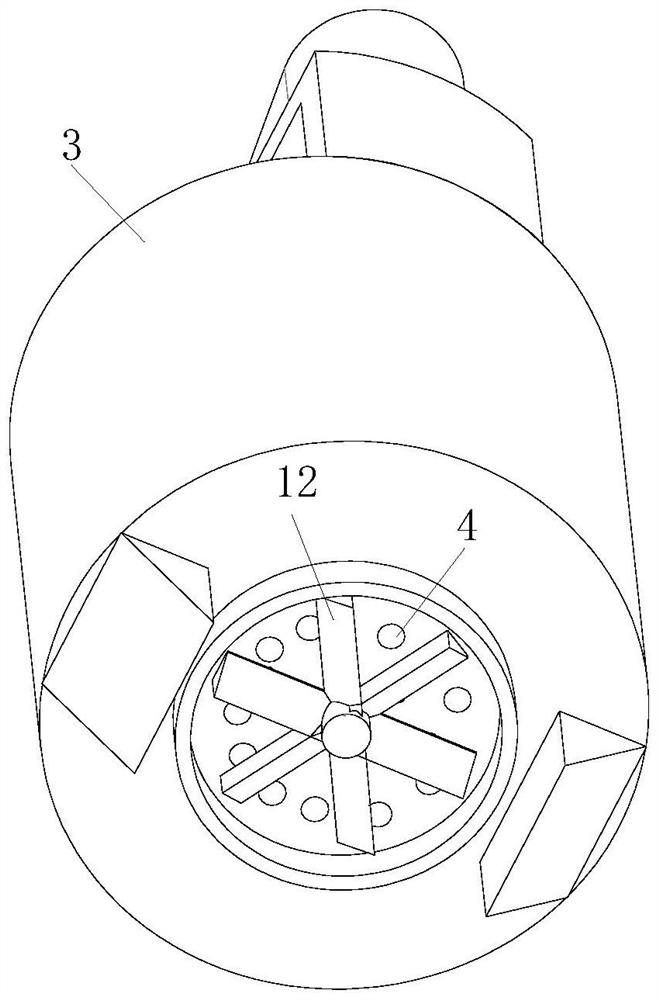

[0067] refer to Figure 8 , Comparative Example 1, as another embodiment of the present invention, wherein the spray end of each atomizing nozzle 13 is rectangular, the spray port of the atomizing nozzle 13 is wavy; It is arranged in a wave shape, so that the sprayed silicone waterproof and oil repellant is in a wave shape, and is sprayed on the fragments in a layered shape, and the two vertical rows of atomizing nozzles 13 are arranged staggered up and down, so that during the falling process of the fragments, organic Under the impact of the silicone water and oil repellent, it is turned upside down, so that the fragments are fully contacted with the silicone water and oil repellent, which improves the surface film coverage of the fragments and reduces the water absorption effect of the fragments.

[0068] Working principle: The air bricks are lifted up and transported to the crushing cylinder 3 through the conveyor belt. The air bricks are crushed by the crushing teeth on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com