Device for loading batteries in disc

A technology of batteries and plastic discs, which is applied in the field of battery loading devices, can solve problems such as unreasonable layout of steel wires, unstable guiding of steel wires, affecting work efficiency, etc., and achieves a system that is not easy to overturn and jam, has a reasonable layout, and has a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

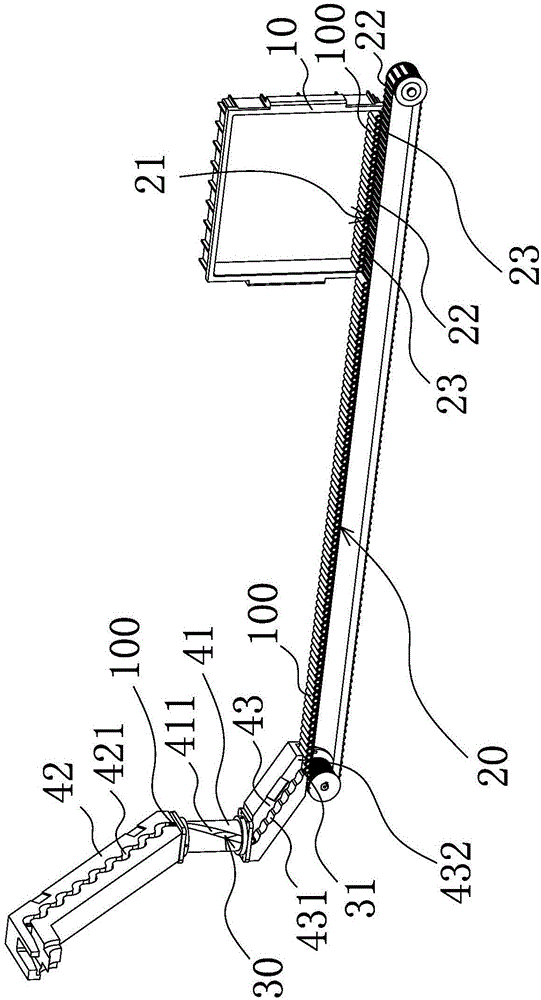

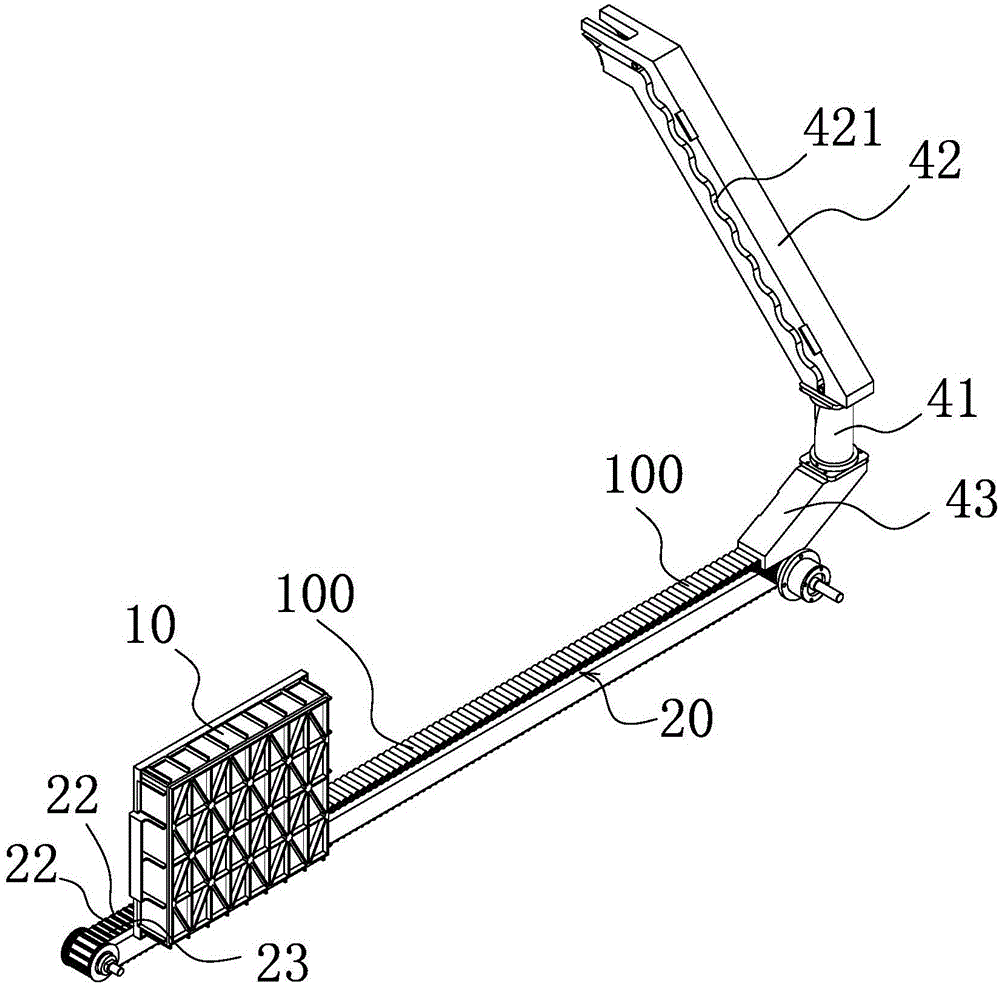

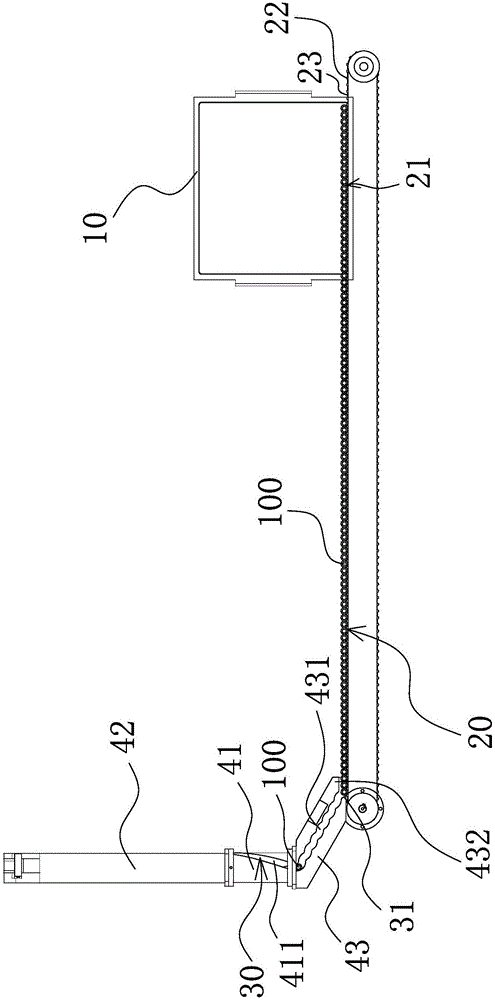

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0035] The invention protects a battery loading device, which is suitable for an automatic battery production line and is used for loading batteries into a plastic tray 10 .

[0036] The structure design of the existing battery loading device is unreasonable. It has a steel wire guide mechanism. The finished battery 100 enters the belt and is brought into the rubber tray 10 after the steel wire is reversed. The steel wire is thin and the transmission is unstable, which greatly reduces the battery 100 transportation. Reliability, and because the steel wire guide is unstable, the connection between the outlet of the steel wire and the belt is easily disconnected, so that the battery 100 passing through the steel wire outlet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com