Formed coke preparation method for replacing carbon raw material used for electric furnace steel making with COREX coke powder

An electric furnace steelmaking and coke powder technology, applied in coke ovens, special forms of dry distillation, petroleum industry, etc., can solve problems such as cost waste, and achieve the effects of reducing production costs, reducing consumption and high value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

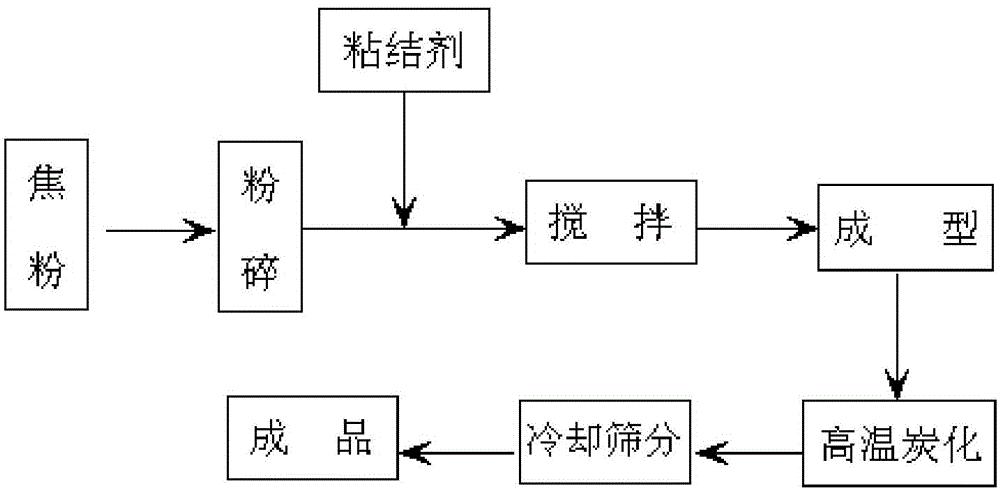

Method used

Image

Examples

Embodiment 1

[0017] COREX coke powder (Ad=17%, VMd=4%) smaller than 5mm is crushed with a pulverizer, the particle size of the crushed coke powder is less than 1mm, put in a drying oven and add 6% binder (bentonite: hydroxyl Methyl cellulose = 1:3), fully mixed and stirred, put it into a molding machine, and cold press it under a pressure of 0.8MPa. Cool naturally, and then sieve to keep the coke particle size at 20-60mm. The performance test results are as follows: RI is 33.24, and RSI is 40.33.

[0018] Put the refined molded coke into the electric arc furnace, add 5.5% molded coke, 2% lime, 0.7% fluorite, 0.4% fire block, and deoxidizer etc. according to 1 ton (scrap steel + pig iron) etc., the materials were put into the electric arc furnace for molten steel smelting at 1580°C, and finally qualified molten steel was obtained. The composition of the molten steel is shown in Table 1.

Embodiment 2

[0020] COREX coke powder (Ad=16%, VMd=3%) smaller than 5mm is crushed with a pulverizer, the particle size of the crushed coke powder is less than 1mm, put in a drying oven and add 8% binder (bentonite: hydroxyl Methyl cellulose = 1:2), fully mixed and stirred, put it into a molding machine, and cold press it under a pressure of 1.2MPa. Cool naturally, and then sieve to keep the coke particle size at 20-60mm. The performance test results are as follows: RI is 32.15, and RSI is 41.23.

[0021] Put the refined molded coke into the electric arc furnace, add 5.5% molded coke, 2% lime, 0.7% fluorite, 0.4% fire block, and deoxidizer etc. according to 1 ton (scrap steel + pig iron) etc., the materials were put into the electric arc furnace for molten steel smelting at 1580°C, and finally qualified molten steel was obtained. The composition of the molten steel is shown in Table 1.

Embodiment 3

[0023] COREX coke powder (Ad=14%, VMd=2%) smaller than 5mm is crushed with a pulverizer, the particle size of the crushed coke powder is less than 1mm, put in a drying oven and add 12% binder (bentonite: hydroxyl Methyl cellulose=5:9), fully mixed and stirred, put it into a molding machine, and cold press it under a pressure of 1.2MPa. Cool naturally, and then sieve to keep the coke particle size at 20-60mm. The performance test results are as follows: RI is 32.47, and RSI is 41.19.

[0024] Put the refined molded coke into the electric arc furnace, add 5.5% molded coke, 2% lime, 0.7% fluorite, 0.4% fire block, and deoxidizer etc. according to 1 ton (scrap steel + pig iron) etc., the materials were put into the electric arc furnace for molten steel smelting at 1580°C, and finally qualified molten steel was obtained. The composition of the molten steel is shown in Table 1.

[0025] Table 1 molten steel composition

[0026] Element

[0027] According to a method for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com