Mining- machine-based slowly inclined thin ore vein mechanized continuous mining method

A mining method and mining machine technology, applied in ground mining, underground mining, special mining, etc., can solve the problems of large secondary crushing engineering, high labor intensity of workers, and difficulty in ore transportation, so as to achieve moderate ore lumpiness, High operational safety and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

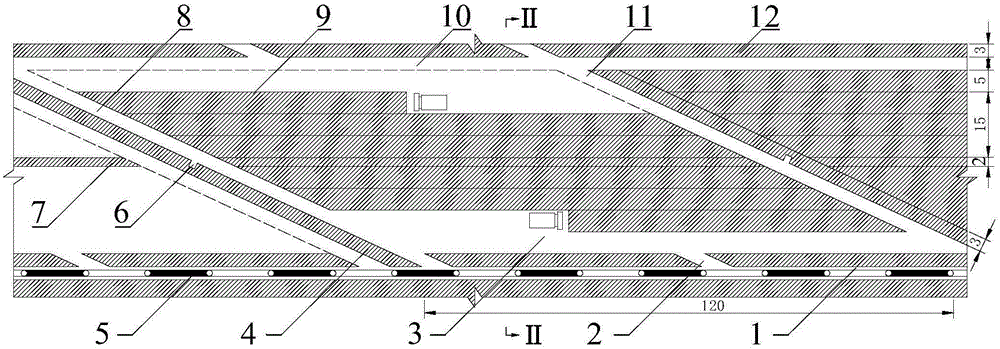

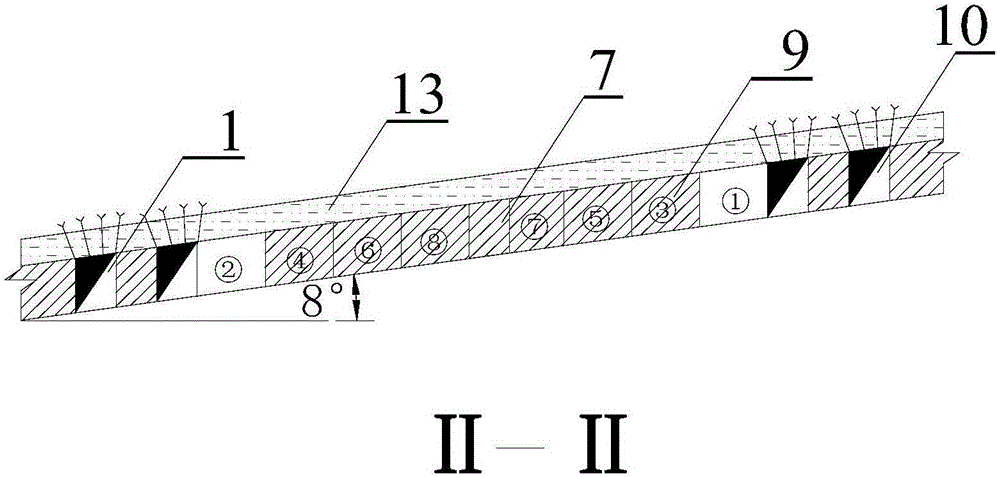

[0029] In the mechanized continuous mining method for gently inclined thin veins provided by the present invention, all development and mining roadways are arranged in the mine vein, which is similar to the mining standard layout form of the traditional mining method, and the middle belt transportation lane is arranged along the direction of the ore body, which also serves as a ventilation roadway. ; Along the middle section of the belt transportation lane, the pseudo-inclined hills are dug at regular intervals to form parallelogram-shaped mining units; in the direction, adjacent mining units are arranged with continuous strips; in the inclination, adjacent mining units are arranged with top or bottom pillars ; Mining quasi-cutting starts from the belt transport lane in the lower middle section, and the mining machine passes through the top or bottom pillars from the boundary of the mining unit to dig the left and right pseudo-inclined uphill to the upper middle section of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com