Multifunctional free splicing type pipe pillow module and using method thereof

A multi-functional, splicing technology, applied in the direction of pipes/pipe joints/fittings, pipe supports, mechanical equipment, etc., can solve the problem of losing control of the spacing between pipes and supporting functions, increasing construction costs and management burden, scalability and versatility limited and other problems, to achieve the effect of improving the efficiency of pipe jacking, reducing the burden of spare parts, and having strong expansion capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

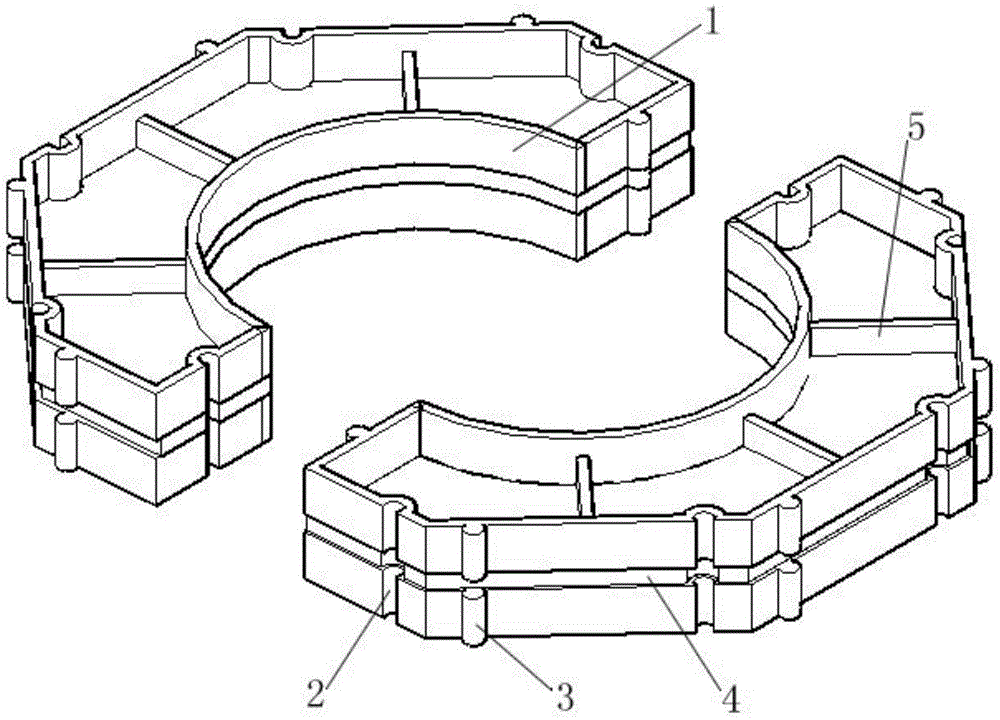

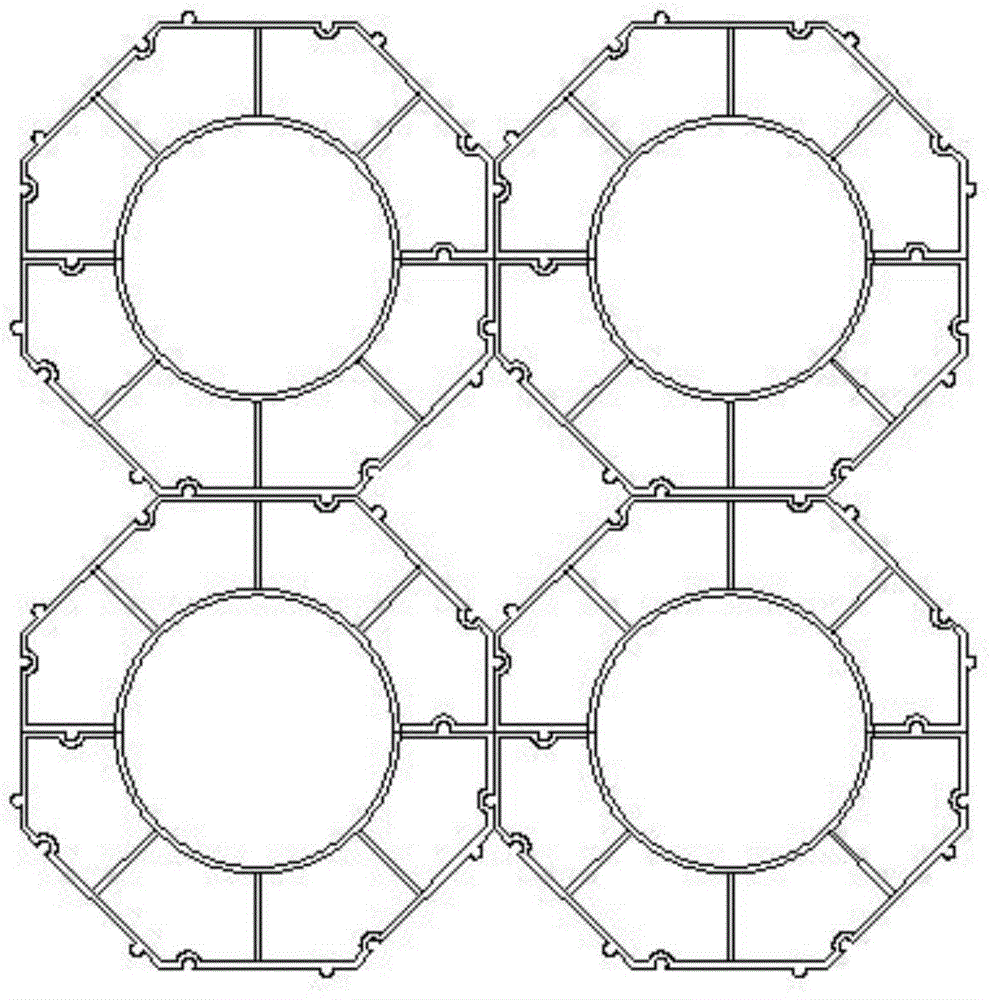

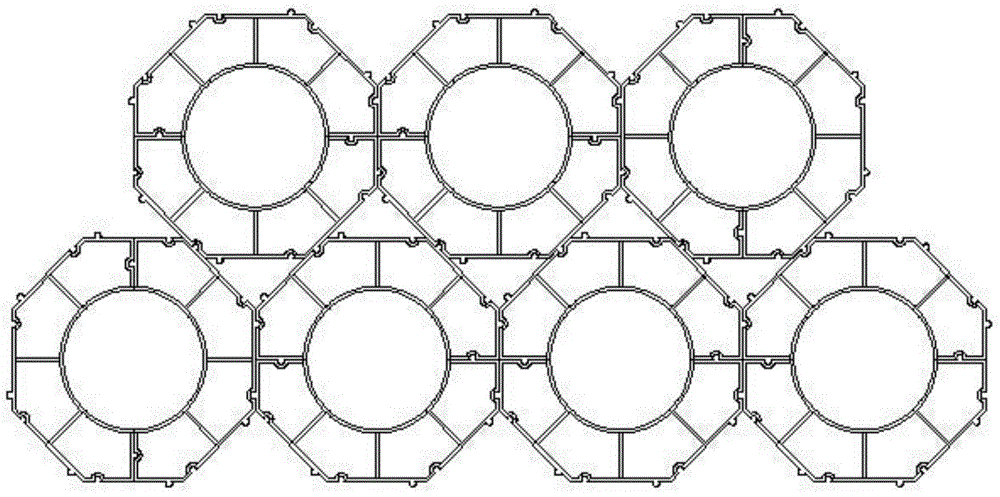

[0030] Such as figure 1 As shown, the multi-functional freely splicable pipe pillow module has a semicircular arc surface 1 on the outer contour of the module. After the two modules are relatively combined, the cross-section of the overall outer contour is a regular octagon, and the two semicircular arcs The surface 1 forms a round hole for carrying pipelines. Except for the semicircular arc surface 1, each group surface of the outer contour of the module is provided with a columnar concave lock 2 or a columnar convex lock 3 extending longitudinally along the module. The columnar concave lock The buckle 2 and the columnar convex lock 3 are alternately arranged next to each other. The columnar concave lock 2 and the columnar convex lock 3 are a concave-convex matching structure corresponding to the cross section. Out of points. In this embodiment, the module is a plastic product, and the cross-section of the outer contour of the module is the part after the regular octagon is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com