Non-contact online measurement method and device for macroscopic displacement of boiler main steam pipe

A non-contact, main steam technology, applied in the direction of photo interpretation, etc., can solve the problems of large monitoring and evaluation errors, lack of online measurement system for key parameters, and failure to consider the interaction of multiple failure mechanisms. The effect of ensuring safety and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

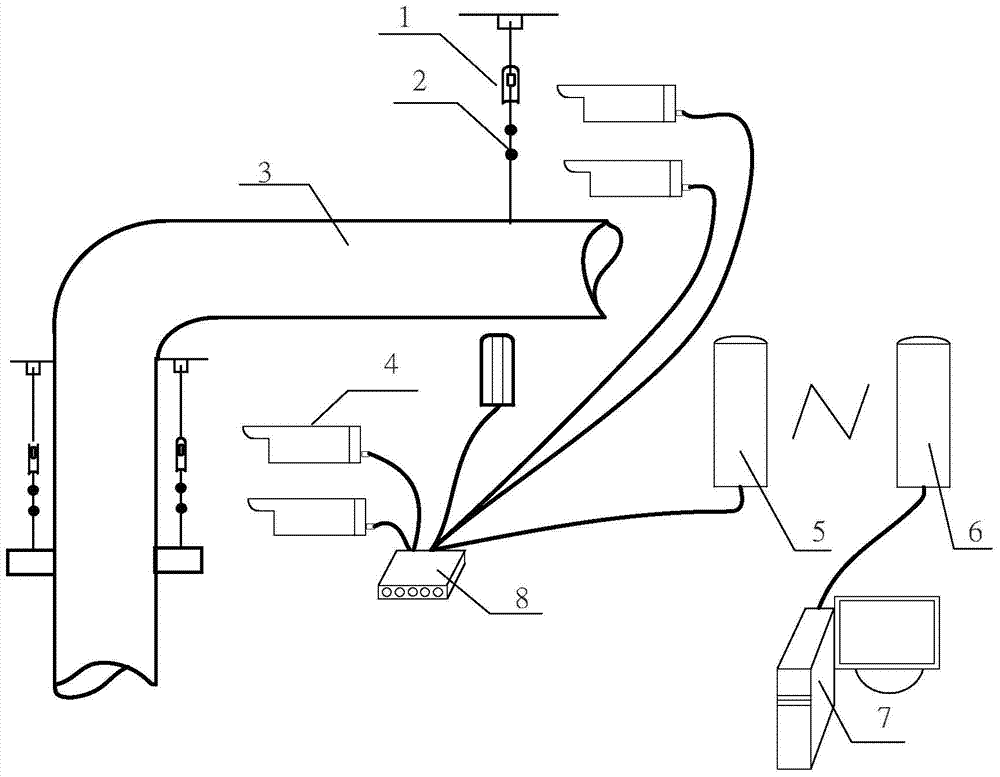

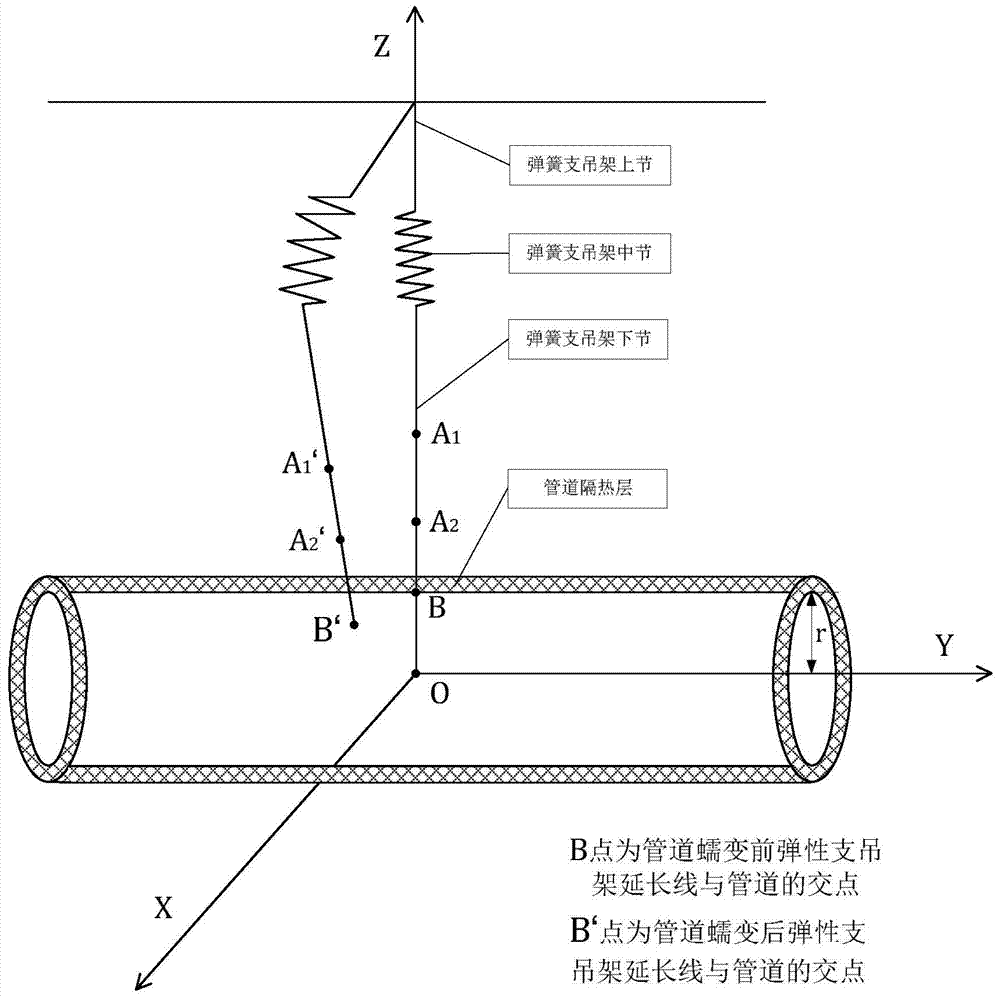

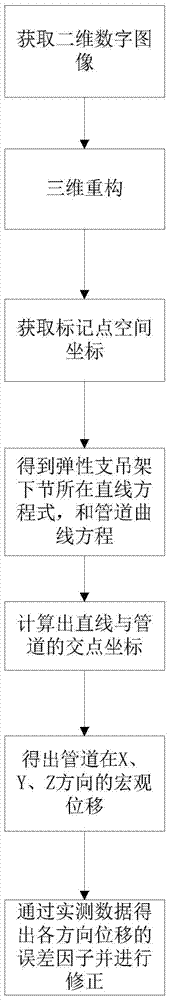

[0050] See figure 1 and figure 2 As shown, the implementation example of the measuring device for the macroscopic displacement of the boiler main steam pipe 3 of the present invention dedicated to the above method includes: setting up the lower section of the elastic support hanger 1 which is simplified as the upper and lower sections of rigid rods and the middle section of spring Two marking points 2, the marking point is a cylinder or a cuboid module with a colored coating on the surface; a binocular high-definition camera 4 corresponding to the number of marking points is fixed non-contact near the elastic support hanger, which is an industrial-grade high-definition camera. Resolution day and night cameras; the shooting direction of the high-definition camera is facing each marki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com