Detection method for silk grafting rate

A technology of grafting rate and testing method, which is applied in the detection field, can solve problems such as failure to adopt products, dependence on test results, identification and quality verification, etc., and achieve the effect of filling the gap in the industry and facilitating product quality verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1), preparation and detection of silk samples with different grafting ratios

[0070] Weigh 0.5g of degummed silk and dry it at 140°C for about 60min until the constant weight is W 1 . Carry out grafting treatment on it, the process is: 200-500% methacrylamide, 3% potassium persulfate, 3% formic acid, the above are the weight of silk, bath ratio 1:50, treat at 85°C for 40min, take samples After washing with water, dry at 140°C until the constant weight is W 2 , calculate its grafting rate according to the weighing method shown in formula 1.

[0071] Formula 1.

[0072] (2) Thermogravimetric analysis and DTG curve peak division processing:

[0073] Adopt Japanese Seiko EXSTAR6000TG / DTA6300 synchronous thermal analyzer, carry out thermogravimetric analysis to the above-mentioned prepared silk samples of different grafting ratios respectively, obtain DTG curve, and use Origin software or XPS software (XPS PEAK4.1) to carry out peak division simulation to it and g...

Embodiment 2

[0142] Sample sending unit: Zhejiang Yashilin Necktie Clothing Co., Ltd. The silk grafting rate measured by weighing method is 32.48%.

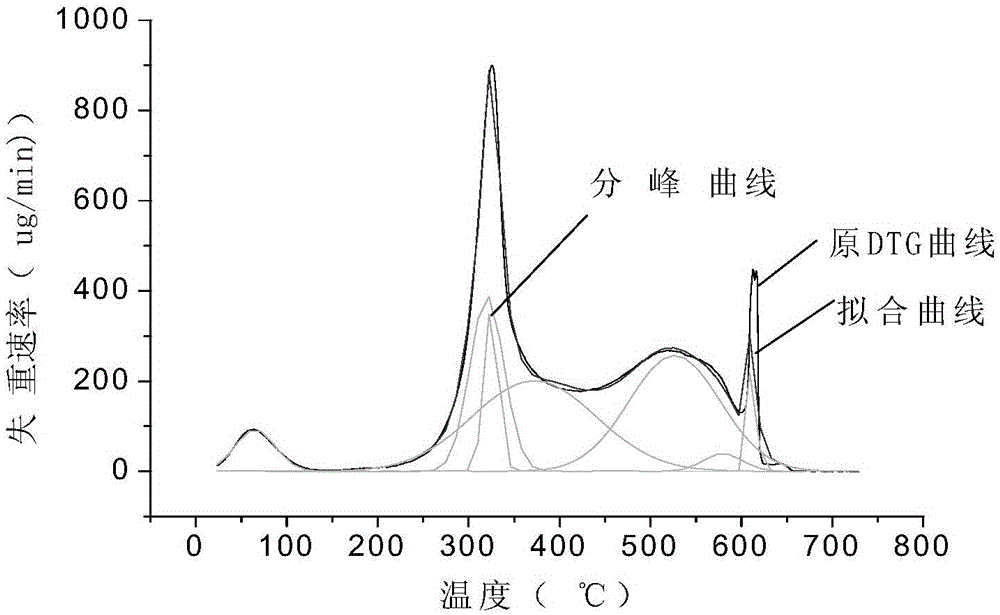

[0143] Samples were taken from four different parts of the sample, and the DTG curve was obtained by thermogravimetric analysis, and the Origin software was used for peak fitting. The results are shown in Figure 22-1 , Figure 22-2 , Figure 22-3 , Figure 22-4 With Table 22-1, Table 22-2, Table 22-3, Table 22-4.

[0144] Origin software peak fitting parameters (detection for the first time) of table 22-1 embodiment 2DTG curve

[0145]

[0146]

[0147] Origin software peak fitting parameters (detection for the second time) of table 22-2 embodiment 2DTG curve

[0148]

[0149] Origin software peak fitting parameters of Table 22-3 embodiment 2DTG curve (the third detection)

[0150]

[0151] Origin software peak fitting parameters (detection for the 4th time) of table 22-4 embodiment 2DTG curve

[0152]

[0153] Adopt the...

Embodiment 3

[0157] Sample sending unit: Zhejiang Babei Necktie Co., Ltd., the grafting rate is 97.66% (weighing method).

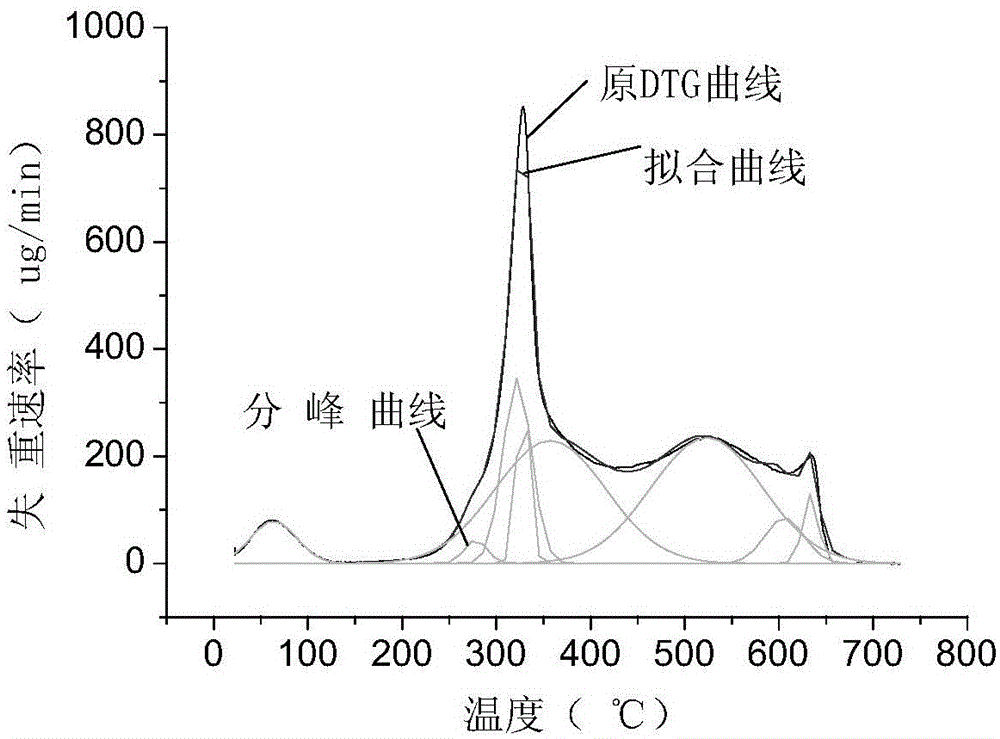

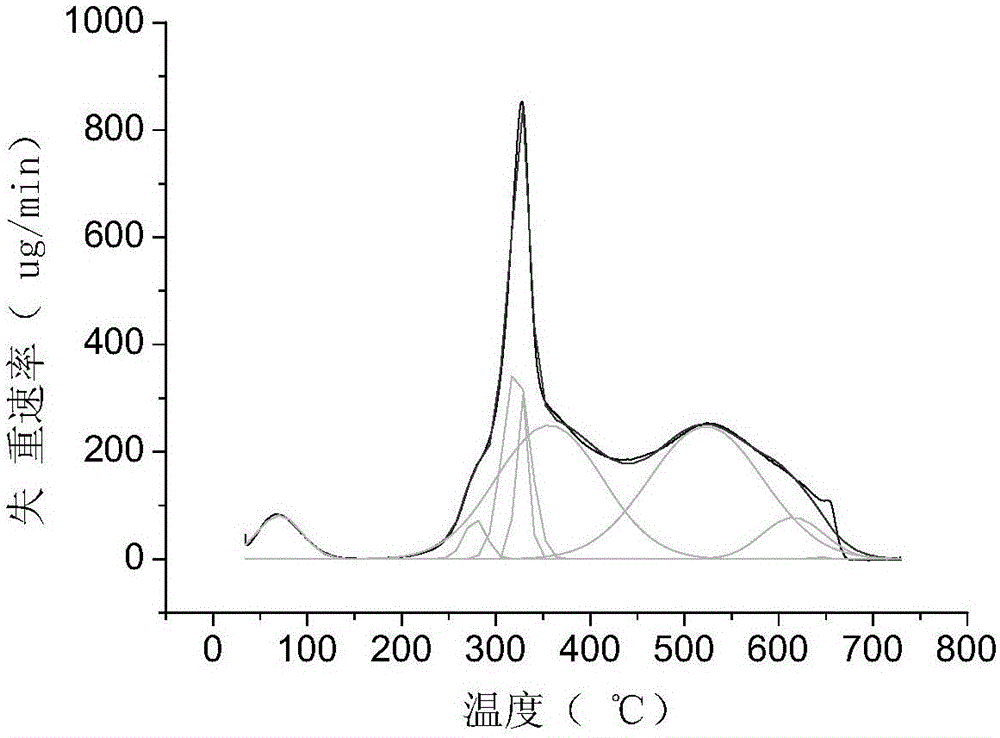

[0158] Samples were taken from four different parts of the sample, and the DTG curve was obtained by thermogravimetric analysis, and the Origin software was used for peak fitting. The results are shown in Figure 23-1 , Figure 23-2 , Figure 23-3 , Figure 23-4 With Table 23-1, Table 23-2, Table 23-3, Table 23-4.

[0159] Origin software peak fitting parameters (detection for the first time) of table 23-1 embodiment 3DTG curve

[0160]

[0161] Origin software peak fitting parameters (second detection) of table 23-2 embodiment 3DTG curve

[0162]

[0163] The Origin software peak fitting parameters of Table 23-3 embodiment 3DTG curve (the third detection)

[0164]

[0165]

[0166] The Origin software peak fitting parameters of Table 23-4 embodiment 3DTG curve (the fourth detection)

[0167]

[0168] Adopt the function formula that the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com