Layout structure and design method of wall-piercing bushing for UHV DC project pole line

A UHV DC, wall bushing technology, used in cable laying equipment, lead-in/pass-through insulators, electrical components, etc., can solve the problem of increased thickness of insulating materials, increased air clearance, and the weight of pole line wall bushings Increase and other problems to achieve the effect of reducing bending moment and avoiding uneven wet flash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

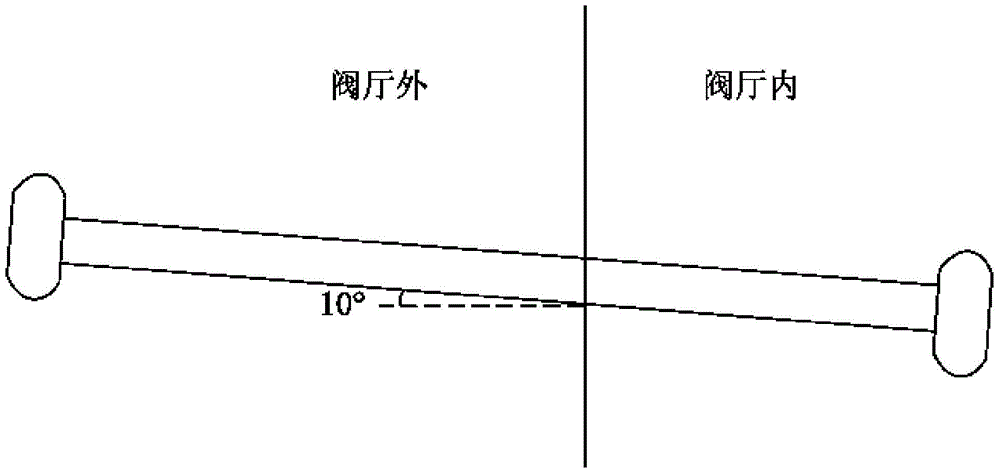

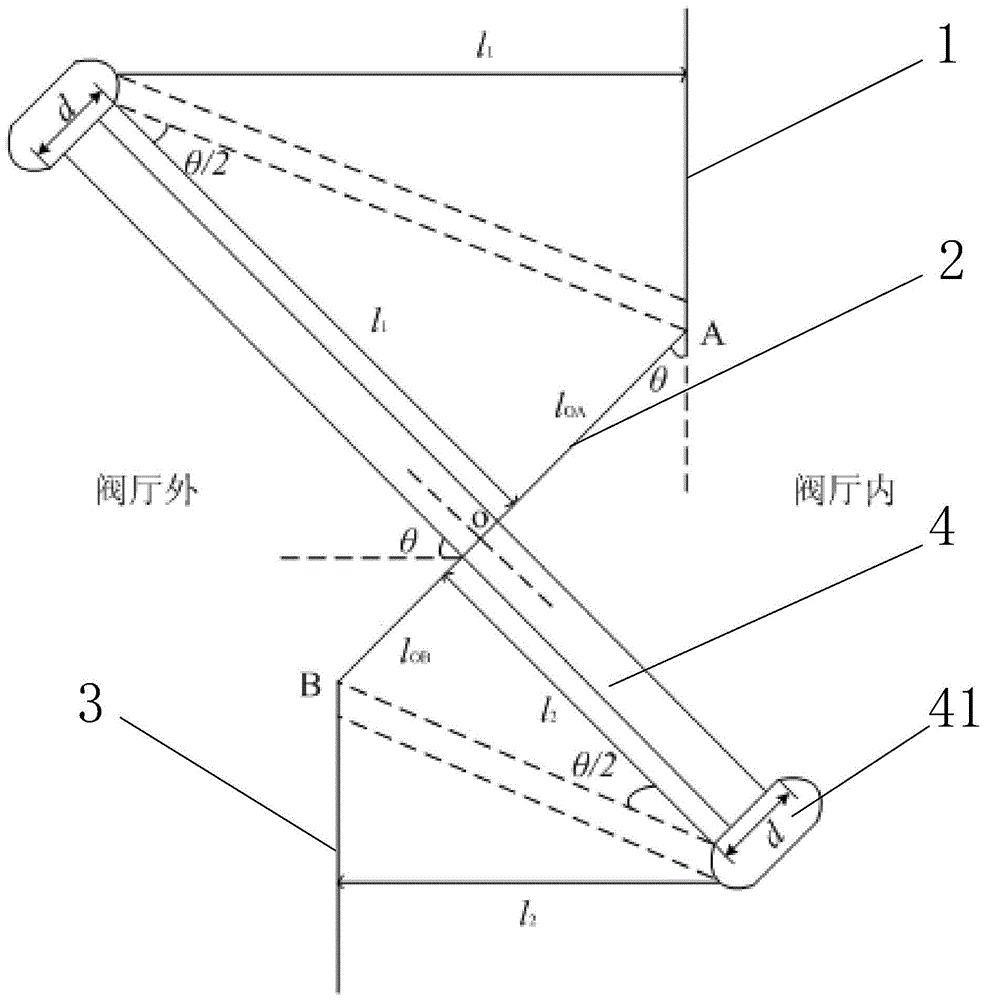

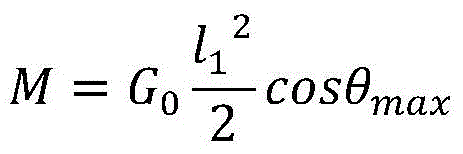

[0029] like figure 2 As shown, the UHV DC project pole line wall bushing layout structure provided by the present invention includes an upper vertical wall 1, and a lower vertical wall staggered by a certain distance from the upper vertical wall 1 in both the horizontal direction and the vertical direction. Wall 3, and the inclined wall 2 connecting the lower end of the upper vertical wall 1 and the upper end of the lower vertical wall 3, the upper vertical wall 1, the inclined wall 2 and the lower vertical wall 3 jointly form the valve hall side wall. The polar line wall-piercing sleeve 4 vertically passes through the inclined wall 2, and the two ends of the polar line wall-piercing sleeve 4 are respectively provided with a pressure equalizing cover 41, and the shortest distance from the pressure equalizing cover 41 outside the valve hall to the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com