Vibration-type wind power generation system

A wind power generation system and vibration-type technology, applied in wind power generation, wind turbines, wind turbine combinations, etc., can solve problems such as the inability to fundamentally overcome the influence of the environment and biology, the difficulty of greatly improving the efficiency of wind turbines, and the low air density. , to achieve high wind energy utilization efficiency, avoid biological and environmental impacts, and implement simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

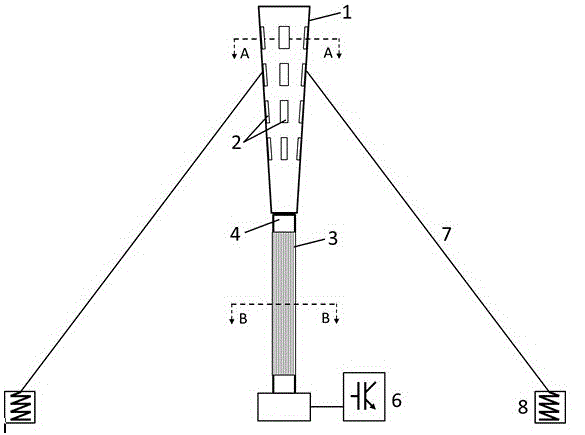

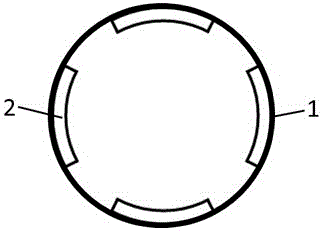

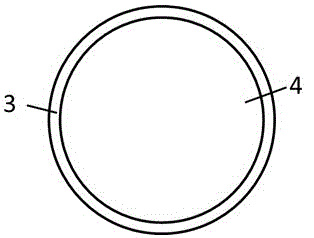

[0024] Such as figure 1 As shown, the structure of the vibration power generation system provided by the present invention is composed of a vibration generator 1, a damping sheet group 2, an elastic support structure 3, a piezoelectric material module 4, a synthetic fiber rope 7 and a spring damping stabilizer 8.

[0025] According to the aerodynamic principle of the action of the airflow on the cylinder, the vibration generator 1 generates periodic vibration, and the damping sheet group 2 is used to effectively control the vibration, so that the piezoelectric material module 4 deforms and moves, and the piezoelectric material of the material The effect generates current, which is then transmitted to the grid or energy storage equipment through the converter. At the same time, in order to ensure the safety of the system under extreme conditions, a safety protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com