Preparing method of burley tobacco and flue-cured tobacco grafted tobacco

A modulation method and technology of burley tobacco, applied in the directions of tobacco, tobacco preparation, application, etc., to achieve the effect of moderate energy, light miscellaneous gas, soft and delicate smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

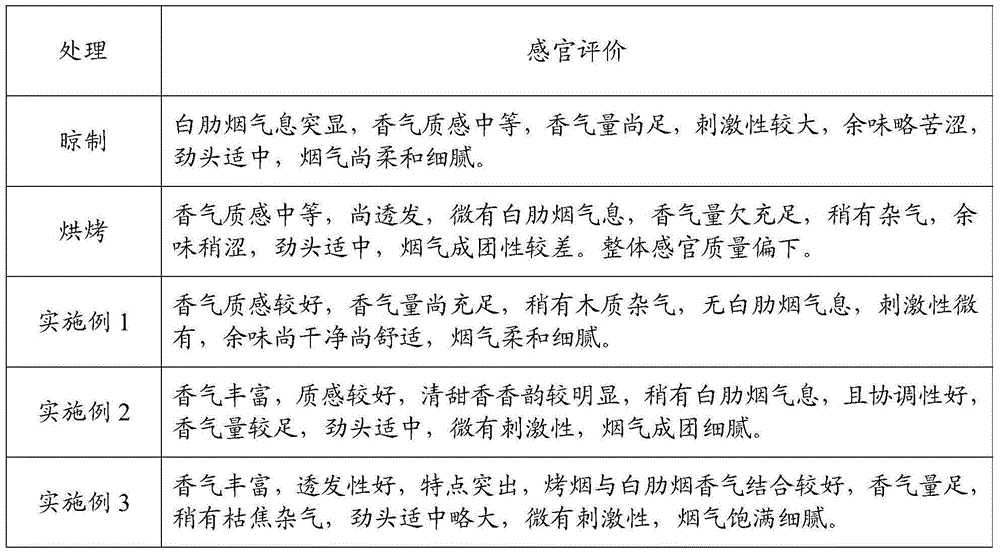

Examples

Embodiment 1

[0011] 1. Withering and yellowing period: After the tobacco leaves are harvested, the stems are classified according to different factors such as the degree of yellowing, water content, and disease, and the main veins are crushed at the same time. Then put it in the barn, do not ignite the fire first, and dry it in the barn until the tobacco leaves wither and turn 50% yellow, then light the fire, raise the temperature to 36°C within 6 hours, and the wet bulb temperature is 34°C, and then increase the temperature at 1°C / h Raise the temperature to 42°C and wet bulb temperature to 36°C, bake the tobacco leaves until they are all yellow, and extend the time appropriately for 8 hours.

[0012] 2. Color fixation period: the tobacco leaves in the step (1) are air-cured in the barn, and the control is relatively moderate 65%. After about 10 days, the color of the tobacco leaves gradually becomes light reddish yellow, and the barn is sealed.

[0013] 3. Dry gluten period: quickly raise...

Embodiment 2

[0015] 1. Withering and yellowing period: After the tobacco leaves are harvested, the stems are classified according to different factors such as the degree of yellowing, water content, and disease, and the main veins are crushed at the same time. Then put it in the barn, do not ignite the fire first, and dry it in the barn until the tobacco leaves wither and turn 60% yellow, then light the fire, raise the temperature to 37°C within 6 hours, and the wet bulb temperature is 35°C, and then increase the temperature at 1°C / h Raise the temperature to 43°C and wet bulb temperature to 37°C, bake the tobacco leaves until they are all yellow, and prolong the time for 10 hours appropriately.

[0016] 2. Color fixation period: the tobacco leaves in the step (1) are air-cured in the barn, and the control is relatively moderate 70%. After about 11 days, the color of the tobacco leaves gradually changes to reddish yellow, and the barn is sealed.

[0017] 3. Dry gluten period: quickly raise ...

Embodiment 3

[0019] 1. Withering and yellowing period: After the tobacco leaves are harvested, the stems are classified according to different factors such as the degree of yellowing, water content, and disease, and the main veins are crushed at the same time. Then put it in the barn, do not ignite the fire first, and dry it in the barn until the tobacco leaves wither and turn 80% yellow, then light the fire, raise the temperature to 38°C within 6 hours, and the wet bulb temperature is 35°C, and then increase the temperature at 1°C / h Raise the temperature to 44°C and wet bulb temperature to 37°C, bake the tobacco leaves until they are all yellow, and extend the time appropriately for 12 hours.

[0020] 2. Color fixation period: the tobacco leaves in the step (1) are air-cured in the barn, and the control is relatively moderate 70%. After about 12 days, the color of the tobacco leaves gradually becomes dark red and yellow, and the barn is sealed.

[0021] 3. Dry gluten period: quickly raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com