Arrangements for removing entrained catalyst particulates from gas

一种催化剂颗粒、气体的技术,应用在催化剂再生/再活化、物理/化学过程催化剂、催化裂化等方向,能够解决催化剂颗粒阻塞、减小催化剂颗粒催化效果等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

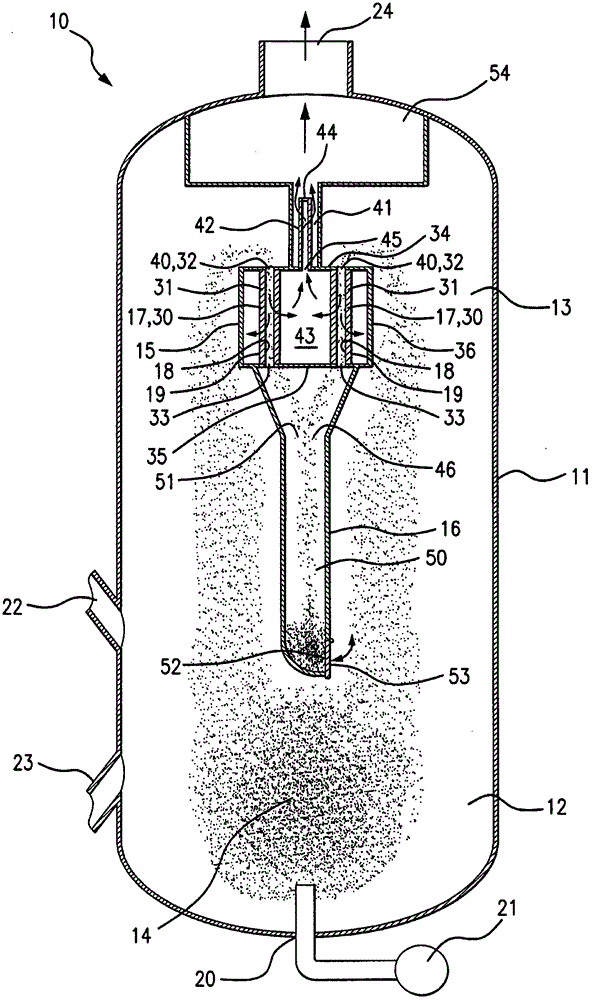

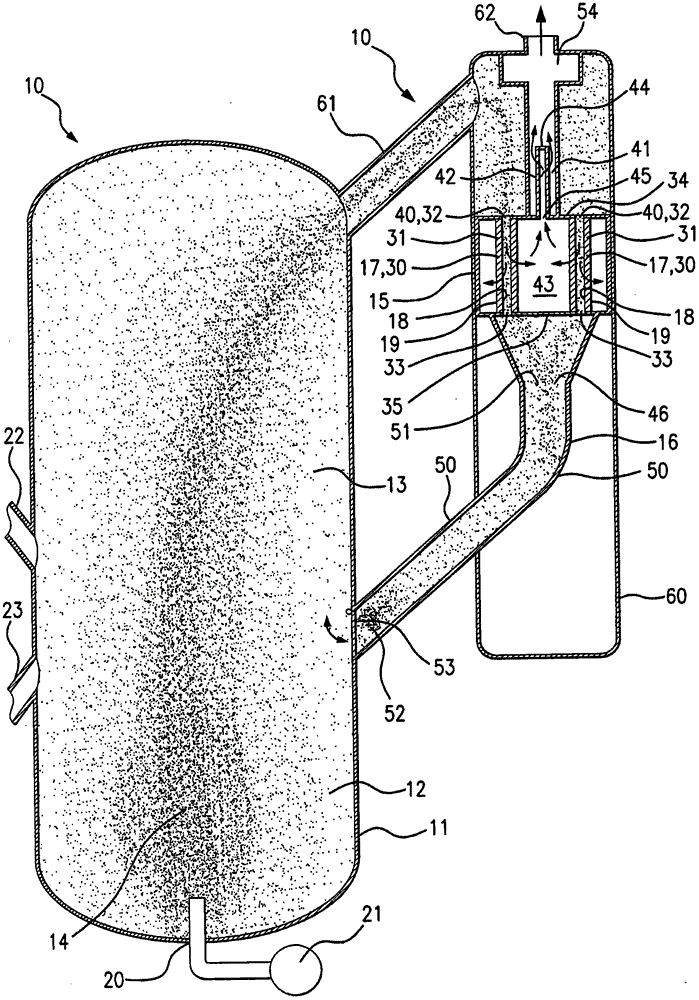

[0008] Many different means for removing entrained catalyst particles from gases (including vapors) may embody the present invention. In one instance of many instances such as figure 1 As shown in , apparatus 10 may include a pressure vessel 11 having a lower region 12 and an upper region 13 . The lower region 12 may be arranged to contain a fluidized bed 14 of catalyst particles suspended in a gas. The upper zone 13 may be arranged to receive gas and entrained catalyst particles from the fluidized bed 14 which are scrubbed or diffused. The device 10 may also include a filter assembly 15 and a sinker leg or tube 16 . The filter assembly 15 includes a permeable filter medium 17 having a feed side 18 and a filtrate side 19 separated from the feed side 18 by means of the filter medium 17 . Dispersed gas and entrained catalyst particles from the fluidized bed 10 may be driven into the filter assembly 15 by pressure inside the pressure vessel or by a blower, fan, compressor (not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com