Ultrasonic cleaning machine

An ultrasonic cleaning machine and ultrasonic technology, applied in the field of ultrasonic cleaning, can solve the problems of limiting the function of the ultrasonic cleaning machine, no space for use, etc., and achieve the effect of improving the cleaning ability, improving the cleaning speed, and improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

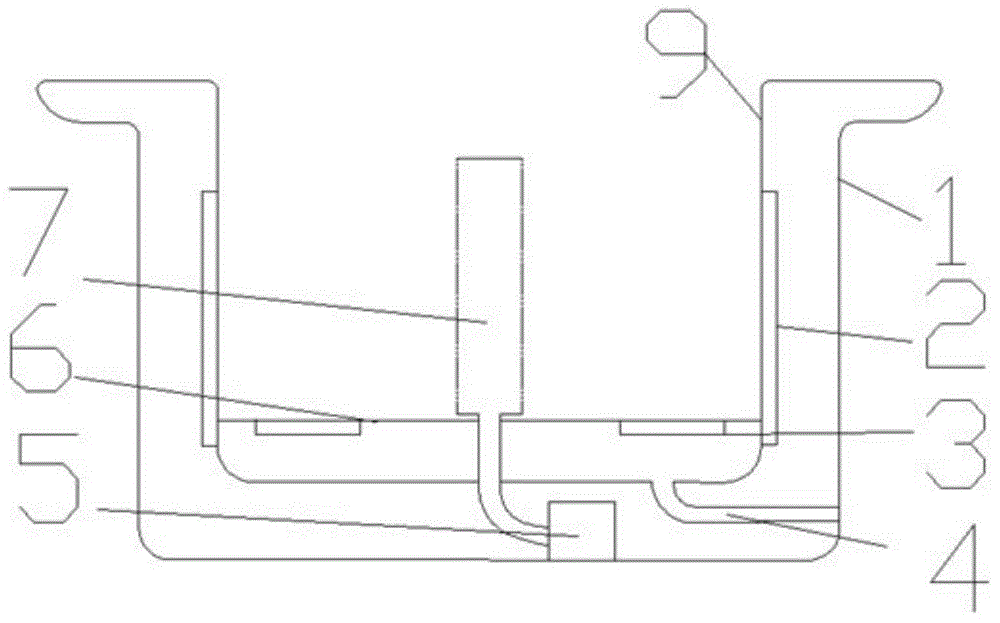

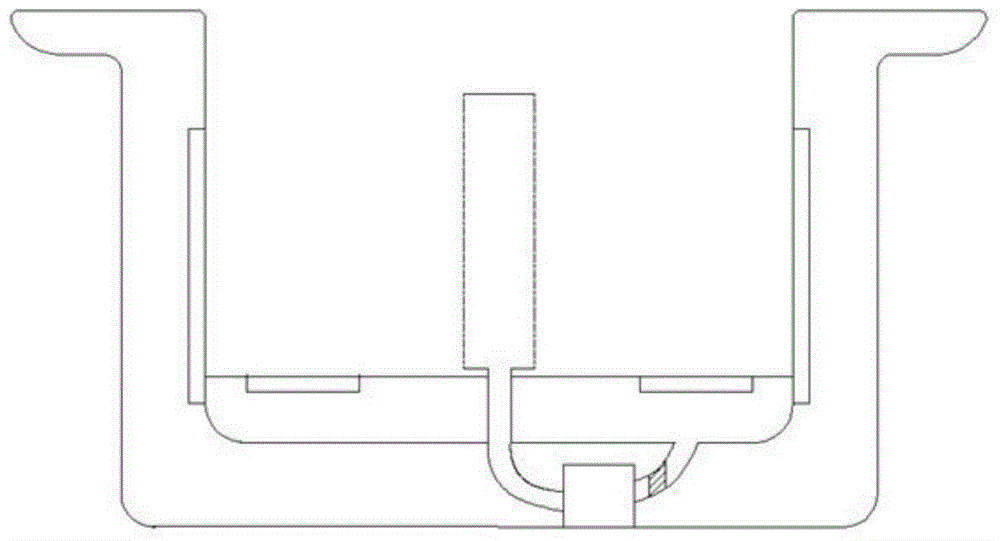

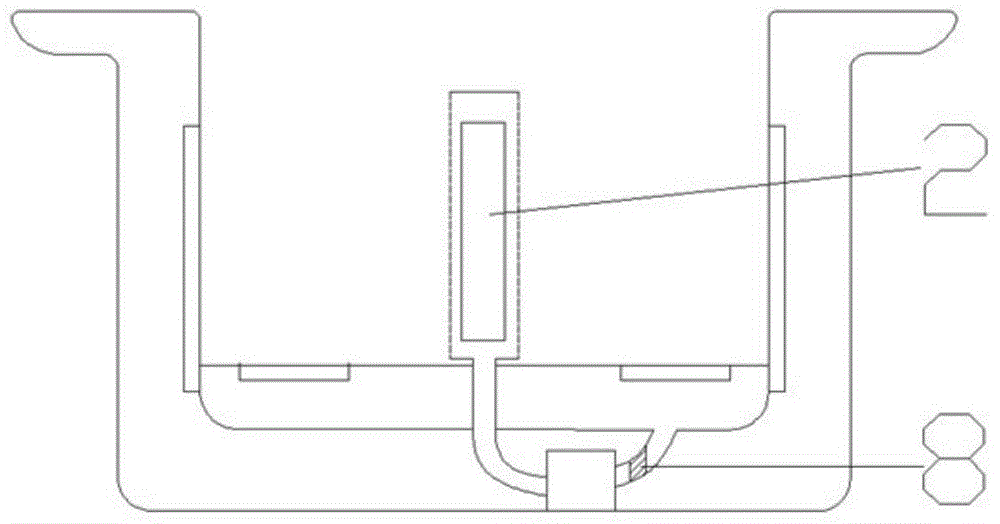

[0026] The ultrasonic cleaning machine includes an ultrasonic device 2, a cleaning tank 9, and an ultrasonic cleaning machine housing 1, wherein the cleaning tank 9 is located inside the ultrasonic cleaning machine housing 1, and the ultrasonic device 2 is fixed on the outer wall of the cleaning tank 9, and also includes a high-pressure water flow device. The high-pressure water flow device includes a high-pressure water spray device 7 and a high-pressure pump 5, the high-pressure water spray device 7 is located in the middle of the cleaning tank 9, and the high-pressure pump 5 is located below the cleaning tank 9 and connected to the high-pressure water spray device 7.

[0027] Wherein, the high-pressure water spraying device 7 is cylindrical.

[0028] Wherein, the side wall of the high-pressure water spray device 7 has uniformly distributed water spray holes.

[0029] Wherein, the diameter of the spray hole is 100um.

[0030] The ultrasonic cleaning machine also includes a ...

Embodiment 2

[0033] The ultrasonic cleaning machine includes an ultrasonic device 2, a cleaning tank 9, and an ultrasonic cleaning machine housing 1, wherein the cleaning tank 9 is located inside the ultrasonic cleaning machine housing 1, and the ultrasonic device 2 is fixed on the outer wall of the cleaning tank 9, and also includes a high-pressure water flow device. The high-pressure water flow device includes a high-pressure water spray device 7 and a high-pressure pump 5, the high-pressure water spray device 7 is located in the middle of the cleaning tank 9, and the high-pressure pump 5 is located below the cleaning tank 9 and connected to the high-pressure water spray device 7.

[0034] Wherein, the high-pressure water spraying device 7 is cylindrical.

[0035] Wherein, the side wall of the high-pressure water spray device 7 has uniformly distributed water spray holes.

[0036] Wherein, the diameter of the spray hole is 2mm.

[0037] The ultrasonic cleaning machine also includes a vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com