A metal composite strip longitudinal wrap forming device

A metal composite belt and longitudinal wrap forming technology, applied in the direction of metal extrusion dies, etc., can solve the problems of looseness, broken metal belt, water seepage, etc., and achieve the effect of preventing edge warping, wrapping tightly, and solving water seepage problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

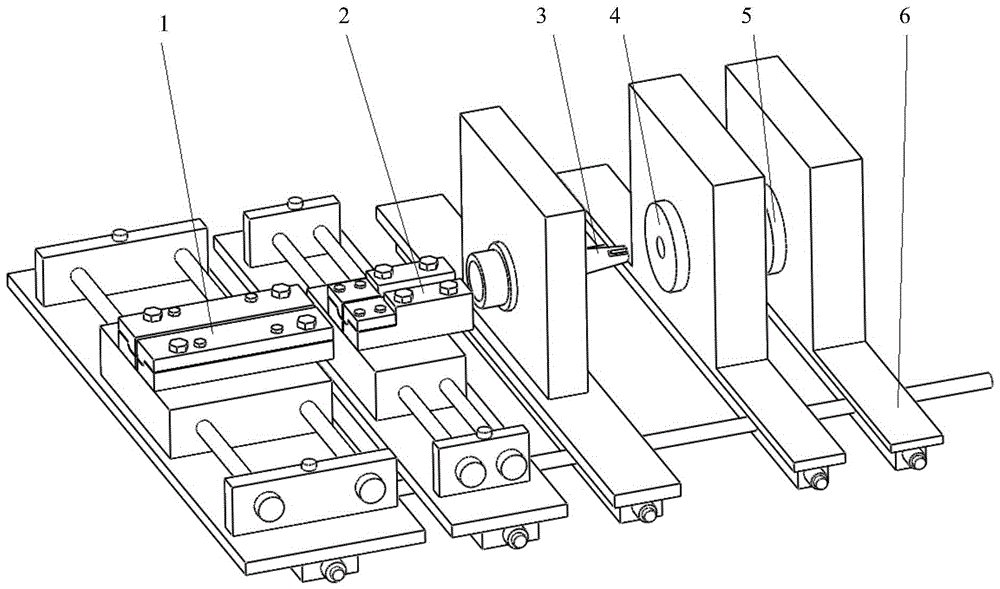

[0041] Such as figure 1 As shown, the metal composite strip longitudinal wrapping forming device of the present invention includes an adjustment platform 6 and a metal composite strip longitudinal wrap forming die arranged on the adjustment platform 6 .

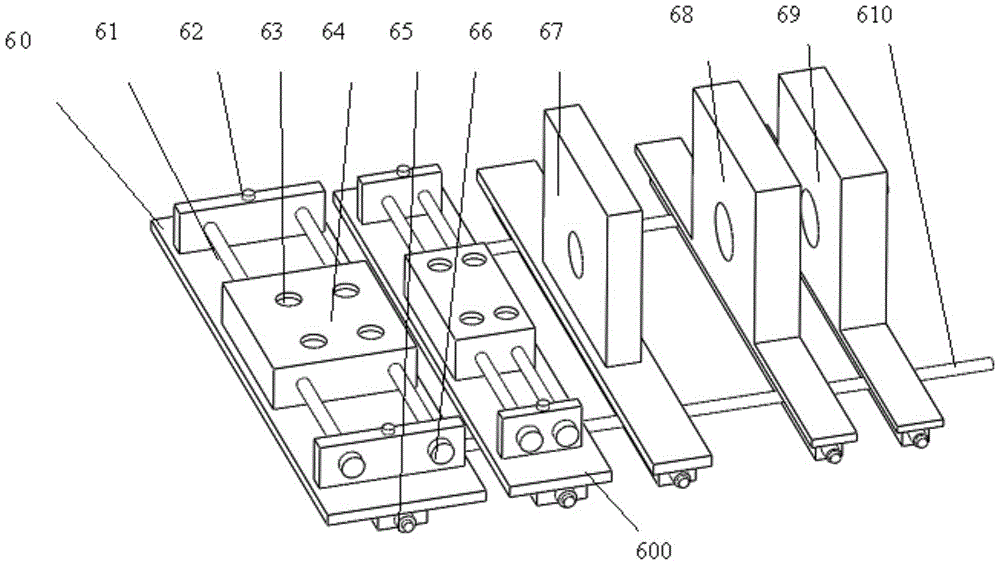

[0042] Among them, such as figure 2 As shown, the adjustment platform 6 includes a sizing mold fixing bracket 69, a forming mold fixing bracket 68, an overlapping mold fixing bracket 67, a second preforming mold fixing platform 600 and a preforming mold fixing bracket 600 connected sequentially by a pair of parallel distributed lateral movement screw rods 610. Forming mold fixed table 60. The sizing die fixed support 69, the molding die fixed support 68 and the overlapping mold fixed support 67 set up a rectangular frame structure on the horizontal shelf; The two sides of the plate are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com