Automatic assembling machine for spring seats

A spring seat and assembly machine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of assembly size error, low efficiency, and poor consistency, and achieve good assembly consistency, high assembly accuracy, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

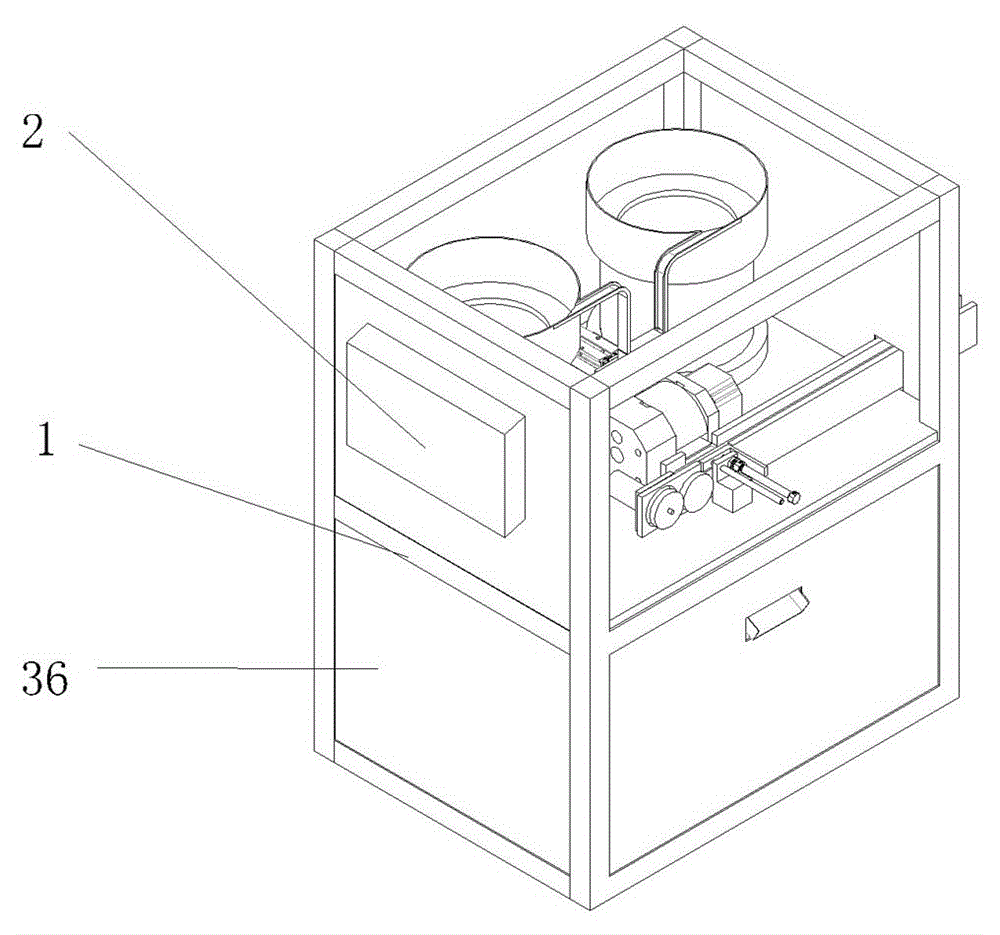

[0027] Such as figure 1 As shown, a spring seat automatic assembly machine includes a frame 1, and a numerical control operation panel 2 is installed on one side of the frame 1. The frame is a frame structure, adopts aluminum profiles as the frame, and is designed as an integrated frame. A housing 36 is installed on the frame to cover the automatic assembly mechanism.

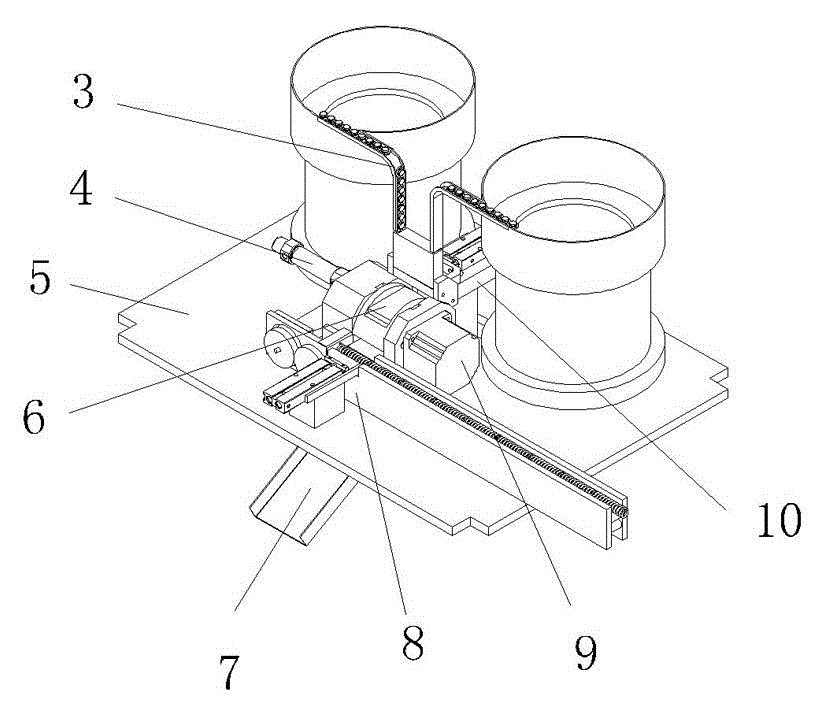

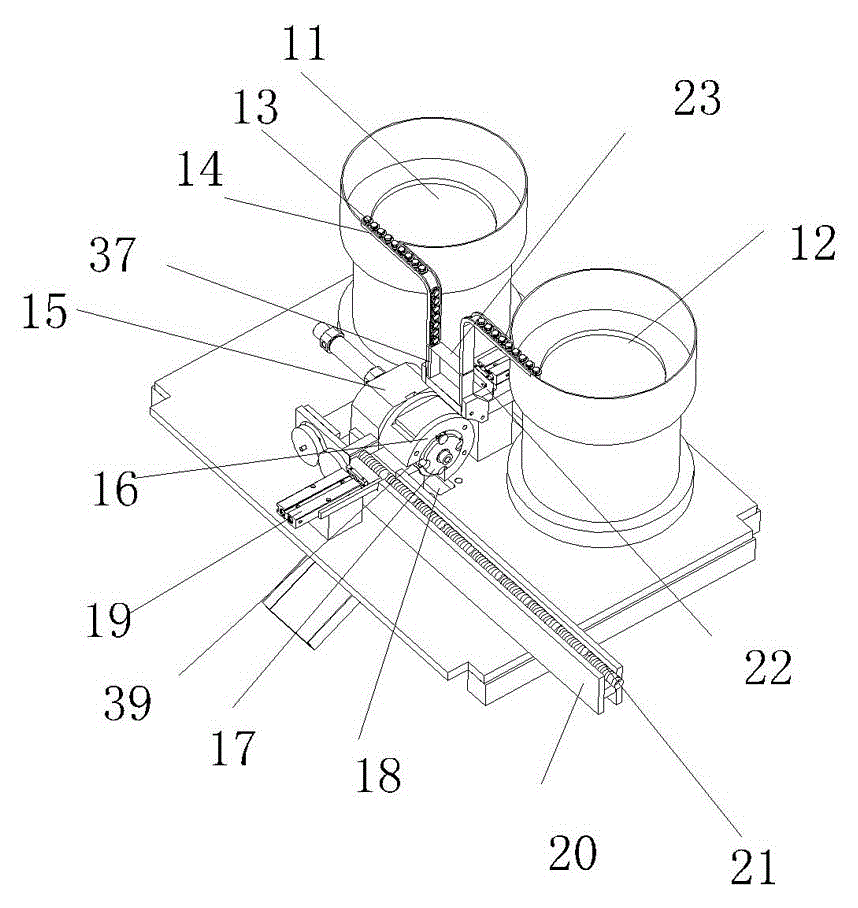

[0028] Such as figure 2 As shown, a table top 5 is installed on the frame, a spring seat feeding mechanism 3 is installed on the table top 5, and a full material stop device is provided at the outlet of the feeding mechanism 3, which can save energy, reduce noise and improve service life. The spring seat feeding mechanism 3 is connected with the spring seat feeding mechanism 10, the spring seat feeding mechanism 10 is connected with the spring seat assembly mechanism 6 and is positioned at one side of the spring seat assembly mechanism, and the other side of the spring seat assembly mechanism 6 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com