Longitudinal shearing splitting method of metallic composite

A technology of slitting into strips and composite material boards, which is applied in chemical instruments and methods, layered products, and auxiliary lamination operations, etc., can solve problems such as layering, improve product quality, eliminate adverse effects, and solve layering problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

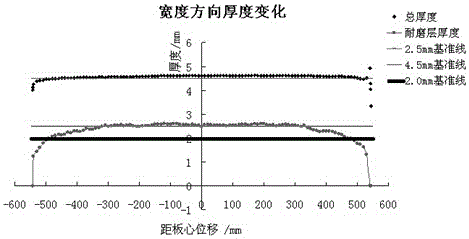

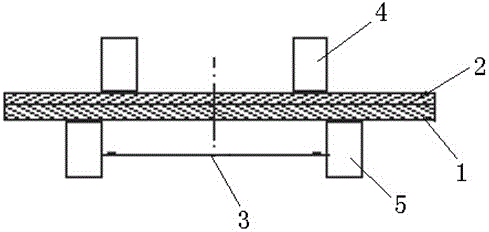

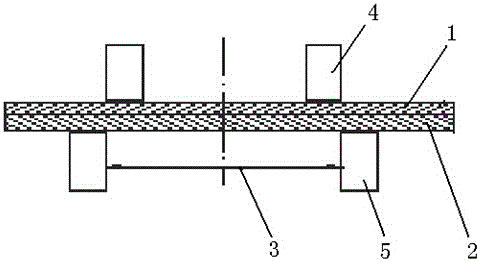

[0025] The specifications of the bimetal composite board are: 4.5×1020×Cmm, the target width of the strips 3 is: 950mm, the thickness of the cladding material 1 is 2.5mm, and the cladding material 1 is 65Mn (use requirements: the minimum thickness of the cladding is guaranteed to be ≥ 2mm ), the thickness of the base material 2 is 2.0mm, and the base material 2 is Q235.

[0026] Since the thickness of the two sides of the bimetallic composite plate will be thinned after rolling, in order to ensure that the thickness of the clad material and the total thickness of the material meet the end use requirements after stripping, the total thickness of the bimetallic composite material and the cladding before stripping The thickness of material 1 is measured separately, and the results show that at -475mm from the center point, the average thickness of cladding material 1 (wear-resistant layer) is: 2.10mm, and the total average thickness of bimetallic composite material is: 4.50mm; the...

Embodiment 2

[0037] The specifications of the bimetallic composite material are: 4.5×1020×Cmm, the target width of the strips 3 is: 420mm, the thickness of the cladding material is 2.5mm, and the cladding material is 65Mn (use requirements: the minimum thickness of the cladding layer is guaranteed to be ≥ 2mm), the thickness of the base layer 2.0mm, base material is Q235.

[0038]Since the thickness of the two sides of the bimetallic composite material will be thinned after rolling, in order to ensure that the cladding thickness and total material thickness of the material after slitting meet the final use requirements, the total cross-sectional thickness and cladding of the bimetallic composite material before slitting The thicknesses of the layered materials were measured separately, and the results showed that the average thickness of the composite material 1 at -460mm from the center point was 2.155mm, and the total average thickness of the bimetallic composite material was 4.502mm; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com