Electric car powertrain

A powertrain and electric vehicle technology, applied in gearboxes, motor transmission technology, and automotive powertrain fields, can solve the problems of large powertrain volume, complex structure, low transmission efficiency, etc., and achieve less kinetic energy loss and high transmission efficiency High and highly integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

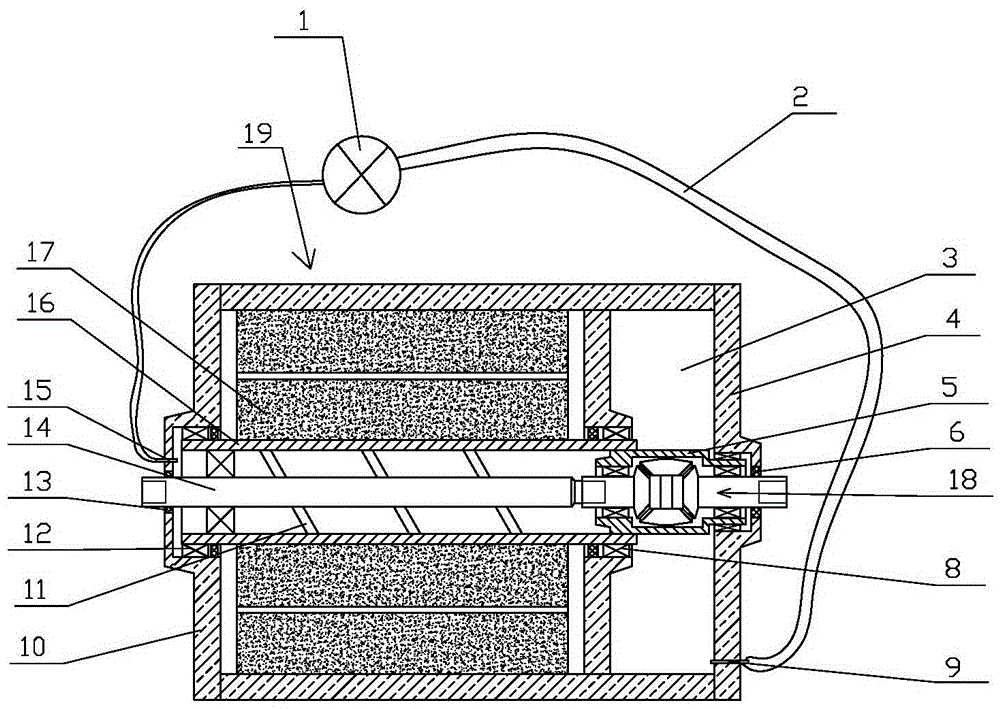

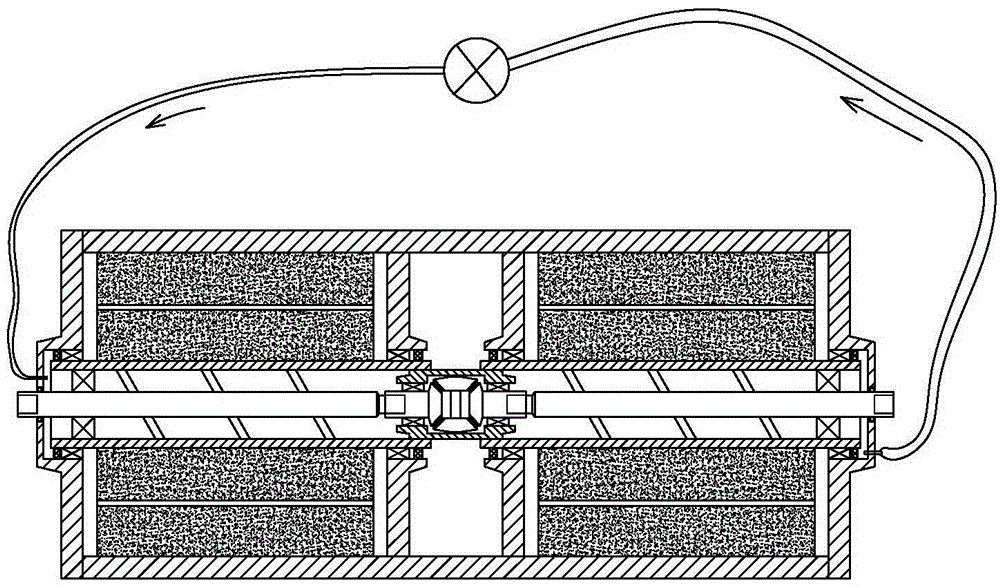

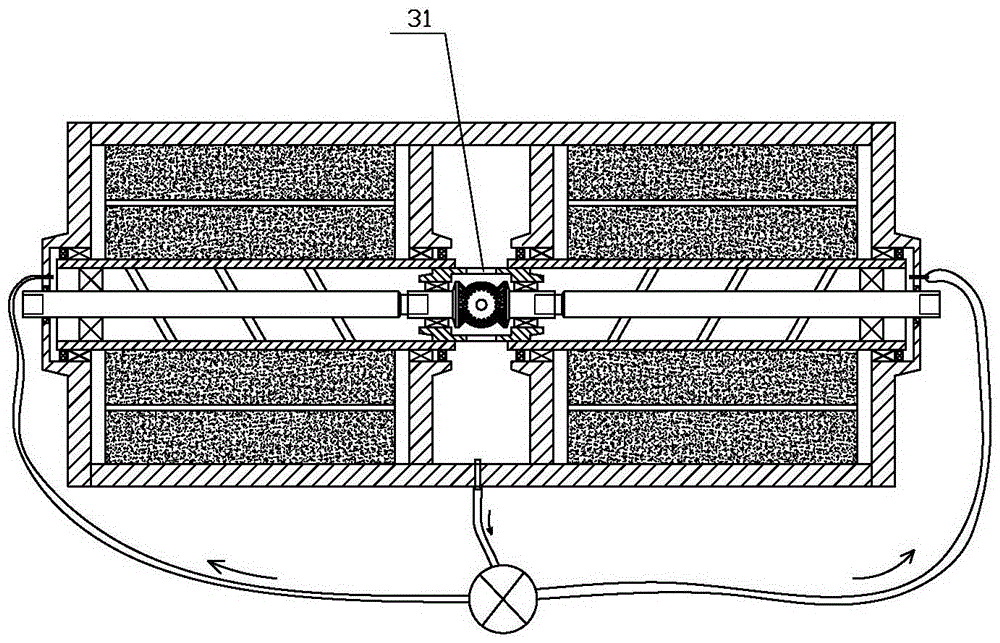

[0022] refer to figure 1 , this figure shows a simple schematic diagram of an embodiment of the automobile power assembly of the present invention, the power assembly is mainly composed of two major parts of the motor 19 and the differential 18, the differential 18 is located at the front end of the motor, and the motor rotor The shaft 16 adopts a hollow structure design, and the front end of the hollow rotor central shaft 16 is directly fixedly connected with the differential case 5 to realize the power transmission between the motor rotor central shaft and the differential. The differential rear output shaft 14 is arranged in the rotor central shaft 16 through a bearing, and the differential rear output shaft 14 is coaxial with the rotor central shaft 16 . The output shafts on the front and rear sides of the differential are respectively used to connect the wheel drive shafts.

[0023] The inner side of the motor rear end cover 10 is provided with a bearing seat for assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com