Sludge degradation treatment method

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of perishable odor, high organic content, restricted transportation and discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0053] Hereinafter, the embodiments of the present invention set up examples to illustrate the present invention. These embodiments are just examples for specifically illustrating the present invention, and those skilled in the art can understand that the scope of the present invention is not limited by these embodiments.

[0054] Wherein, it should be noted that in the following examples, the sludge to be treated is an example of industrial sludge, and the content of heavy metals in industrial sludge is usually high. Therefore, the obtained liquid product is discharged or used for Before sludge pulping, heavy metal stabilizers need to be added to fix heavy metals.

Embodiment 1

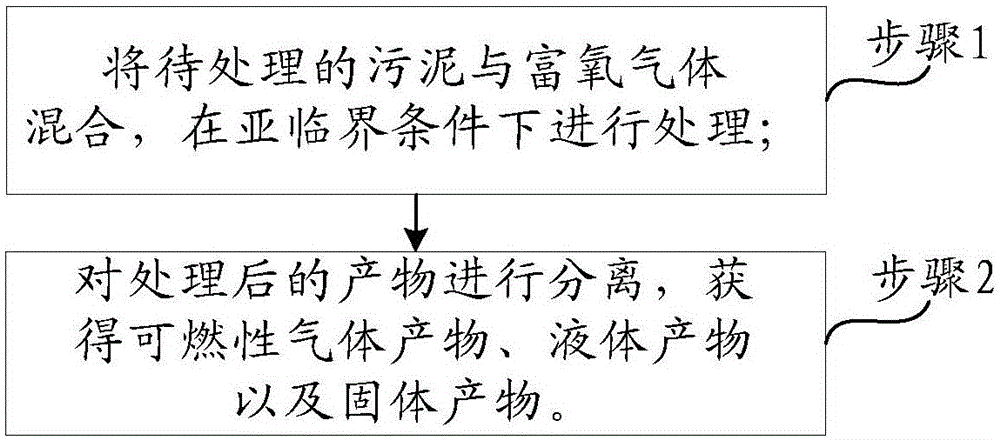

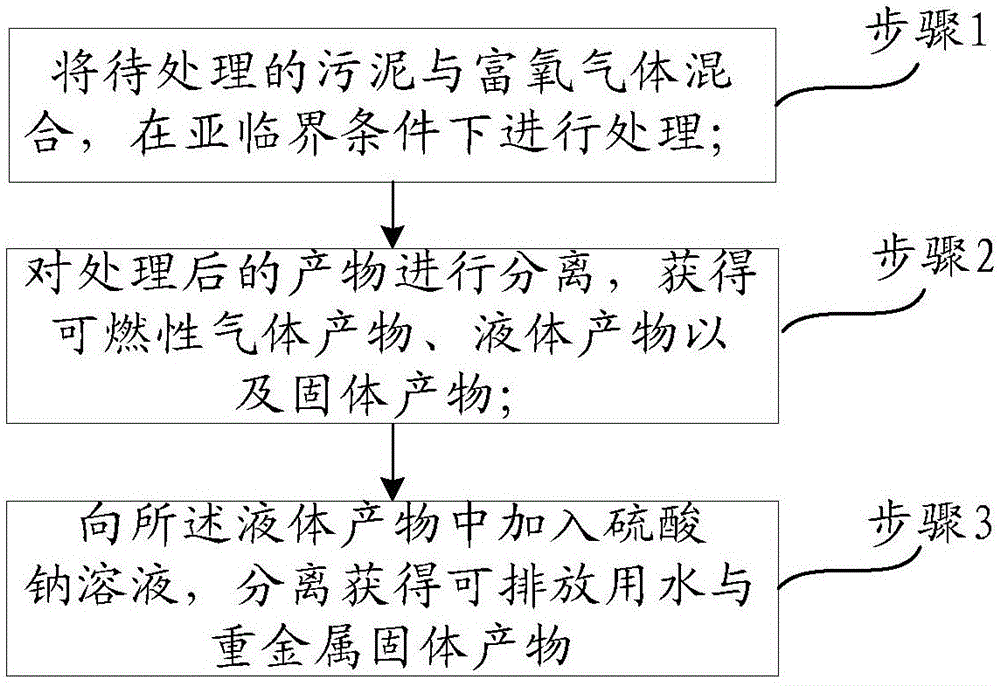

[0056] Embodiment 1 of the present invention provides a kind of sludge degradation treatment method, see figure 2 Shown:

[0057] Step 1) mixing the sludge to be treated with oxygen-enriched gas, and treating it under subcritical conditions;

[0058] Specifically: the sludge is pretreated to prepare a sludge slurry that can be pumped, and oxygen-enriched gas is added to the sludge slurry, wherein the mass of oxygen in the amount of oxygen-enriched gas added is 3 times the theoretical oxygen demand of the sludge %, treated under subcritical conditions (22MPa, 373°C).

[0059] Step 2) separating the treated product to obtain combustible gas products, liquid products and solid products;

[0060] Specifically: a combustible gas product, a solid product (water content 20%) and a liquid product are obtained through one-step separation, wherein the combustible gas product can be directly burned, and the heavy metal content in the liquid product is relatively high and cannot be use...

Embodiment 2

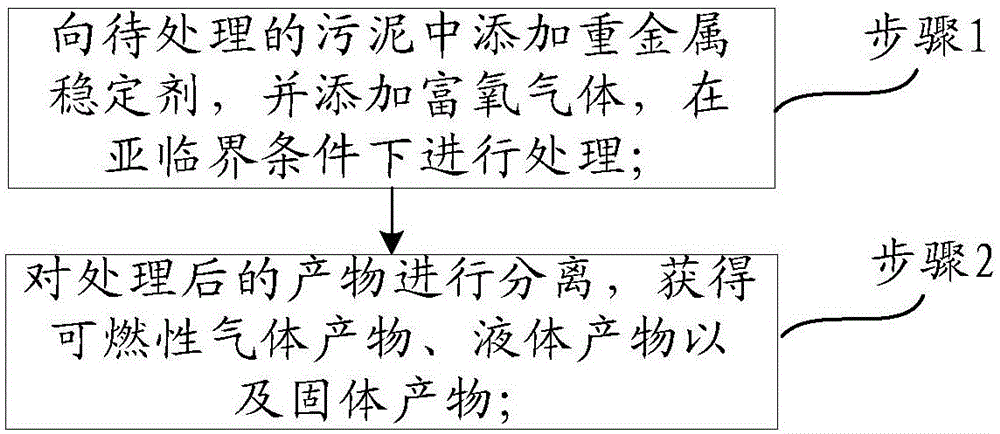

[0065] Embodiment 2 of the present invention provides a kind of sludge degradation treatment method, see image 3 Shown:

[0066] Step 1) adding a heavy metal stabilizer to the sludge to be treated, mixing it with oxygen-enriched gas, and treating it under subcritical conditions;

[0067] Specifically: add calcium hydroxide solids to the sludge to be treated, dissolve the solids by stirring, and prepare sludge slurry. The concentration of calcium hydroxide in the sludge slurry is 100g / L, and the sludge slurry The material is mixed with oxygen-enriched gas after pressurized and preheated, wherein the mass of oxygen in the amount of oxygen-enriched gas added is 30% of the chemical oxygen demand of the sludge raw material, and it is treated under subcritical conditions (9MPa, 280°C).

[0068] Step 2) separating the treated product to obtain combustible gas products, liquid products and solid products;

[0069] Specifically: a combustible gas product, a solid product (20% water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com