A method of using microbial flocculation to form granular sludge to treat zinc-containing wastewater

A technology of microbial flocculation and granular sludge, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of granular sludge settling performance is not very ideal, low molecular weight, expensive and other issues, to achieve the effect of clean and sustainable production process, low production cost and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

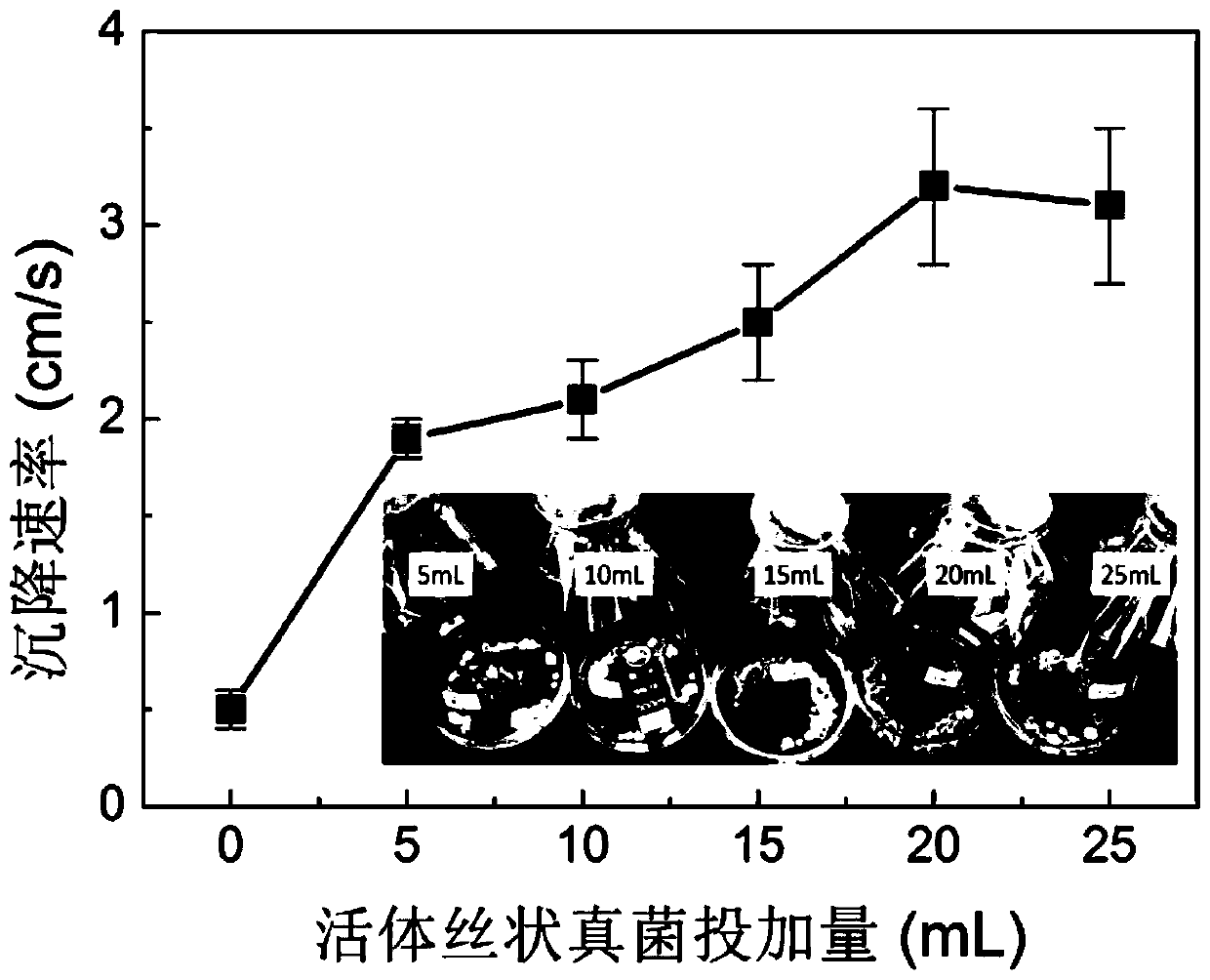

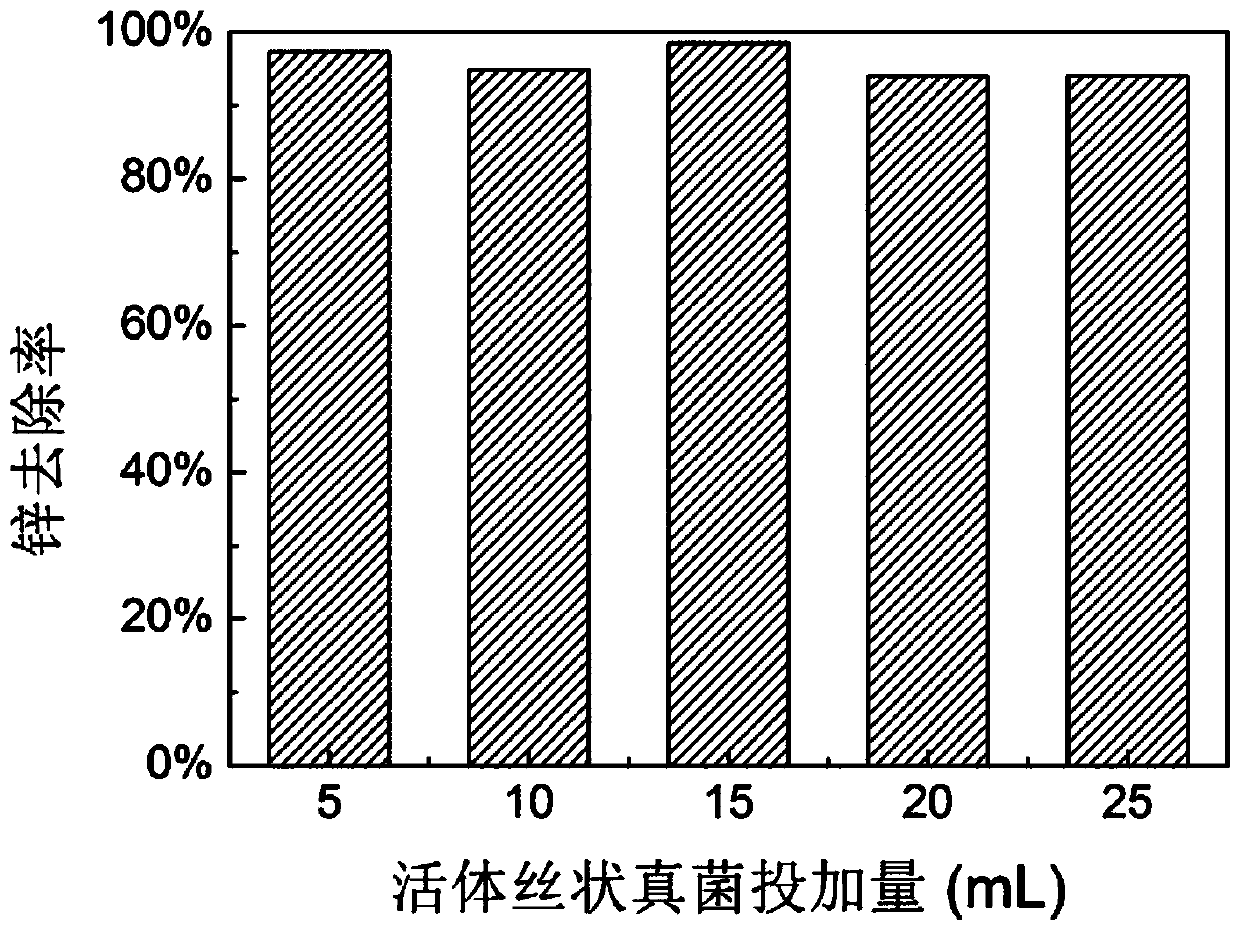

[0031] Inoculate Aspergillus (CGMCC No.5858) onto potato solid medium at 37°C and cultivate for 7 days to activate. The activated Aspergillus was inoculated into 100mL liquid potato medium, and cultured at 30°C for 3 days. After 3 days of growth, Aspergillus formed loose mycelium balls. Using 1500rpm magnetic stirring for 5 hours to break up the large mycelium balls to obtain loose mycelium. Take 5 mL of the dispersed bacterial liquid and re-inoculate it into 100 mL of liquid potato medium, and incubate at 30°C for 48 hours to form a large number of small mycelial balls with a diameter of about 2 mm. Adjust the pH value of the living filamentous fungus to 9.0±0.2. The living filamentous fungus is stored in a Erlenmeyer flask for future use.

[0032] A reaction beaker was placed on a constant temperature magnetic stirrer, and 100 mL of a ZnO-containing suspension (solid concentration: 1.5 g / L) was added to it. The reaction temperature was controlled at 25° C., and the rotati...

Embodiment 2

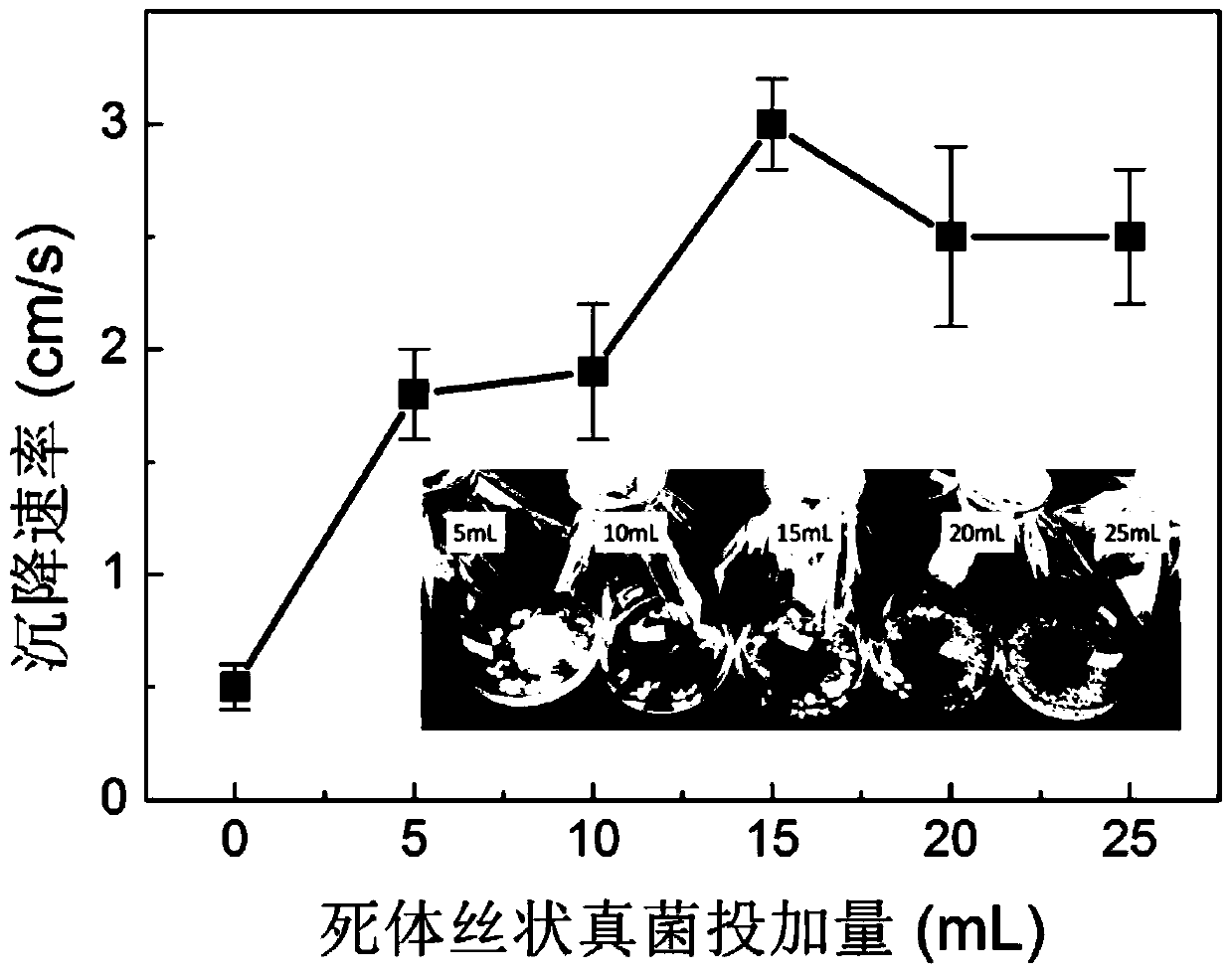

[0035]Inoculate Aspergillus (CGMCC No.5858) onto potato solid medium at 37°C and cultivate for 7 days to activate. The activated Aspergillus was inoculated into 100mL liquid potato medium, and cultured at 30°C for 3 days. After 3 days of growth, Aspergillus formed loose mycelium balls. Using 1500rpm magnetic stirring for 5 hours to break up the large mycelium balls to obtain loose mycelium. Take 5 mL of the dispersed bacterial liquid and re-inoculate it into 100 mL of liquid potato medium, and culture it at 30°C for 48 hours to form a large number of small mycelial balls with a diameter of about 2 mm. Glutaraldehyde solution was added to inactivate. The concentration of glutaraldehyde after addition was 2.5%. It was left standing at room temperature for 6 hours, and its pH value was adjusted to 9.0±0.2. The inactivated mycelium was placed in a glass bottle for later use.

[0036] A reaction beaker was placed on a constant temperature magnetic stirrer, and 100 mL of a ZnO-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com