Method for treating copper-containing wastewater by forming granular sludge through microorganism sediment

A technology of granular sludge and microbial flocculation, used in biological water/sewage treatment, biological treatment devices, water/sludge/sewage treatment, etc. problems, to achieve the effect of clean and sustainable production process, low production cost and reduced disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Inoculate Aspergillus (CGMCC No.5858) onto potato solid medium at 37°C, and cultivate for 7 days to activate. The activated Aspergillus was inoculated into 100mL liquid potato medium, and cultured at 30°C for 3 days. After 3 days of growth, Aspergillus formed loose mycelium balls. Use 1500rpm magnetic stirring to disperse large mycelium balls to obtain loose mycelium. Take 5 mL of the dispersed bacterial liquid and re-inoculate it into 100 mL of liquid potato medium, and incubate at 30°C for 48 hours to form a large number of small mycelial balls with a diameter of about 2 mm. Adjust the pH value of the living filamentous fungus to 11.0±0.2. The living filamentous fungus is stored in a Erlenmeyer flask for future use.

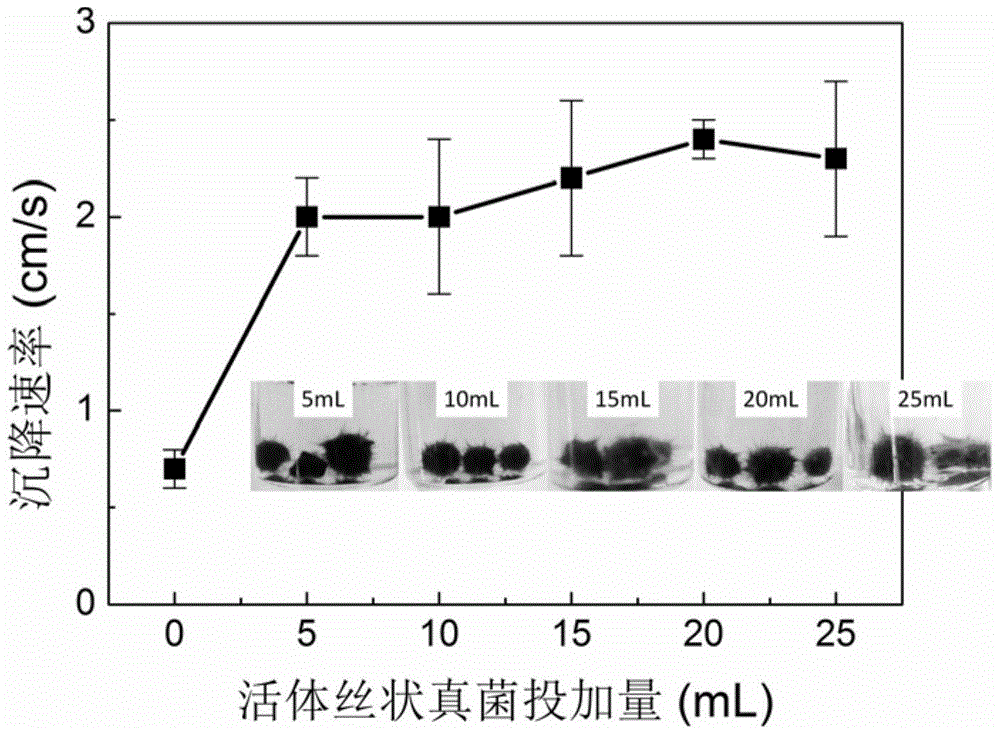

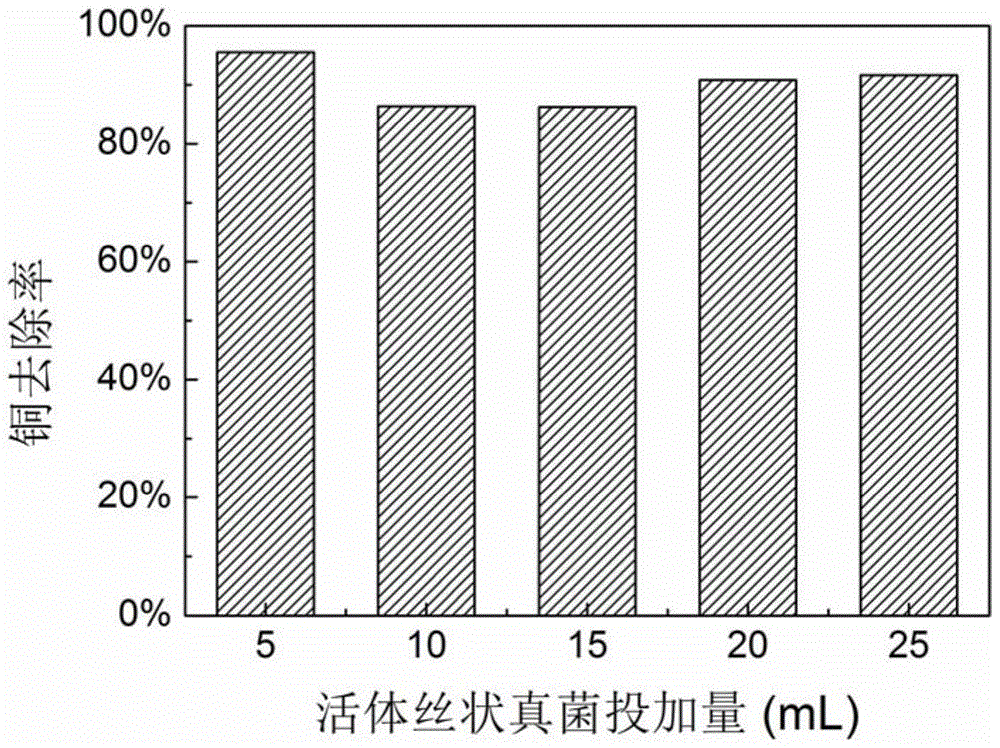

[0033] A reaction beaker was placed on a constant temperature magnetic stirrer, and 100 mL of a suspension containing CuO seed crystals (solid concentration: 2.5 g / L) was added thereto. The reaction temperature was controlled at 25° C., and the rotati...

Embodiment 2

[0036]Inoculate Aspergillus (CGMCC No.5858) onto potato solid medium at 37°C, and cultivate for 7 days to activate. The activated Aspergillus was inoculated into 100mL liquid potato medium, and cultured at 30°C for 3 days. After 3 days of growth, Aspergillus formed loose mycelium balls. Use 1500rpm magnetic stirring to disperse large mycelium balls to obtain loose mycelium. Take 5 mL of the dispersed bacterial liquid and re-inoculate it into 100 mL of liquid potato medium, and culture it at 30°C for 48 hours to form a large number of small mycelial balls with a diameter of about 2 mm. Glutaraldehyde solution was added for inactivation. The concentration of glutaraldehyde after addition was 2.5%. It was left standing at room temperature for 6 hours, and its pH value was adjusted to 11.0±0.2. The inactivated mycelium was placed in a glass bottle for later use.

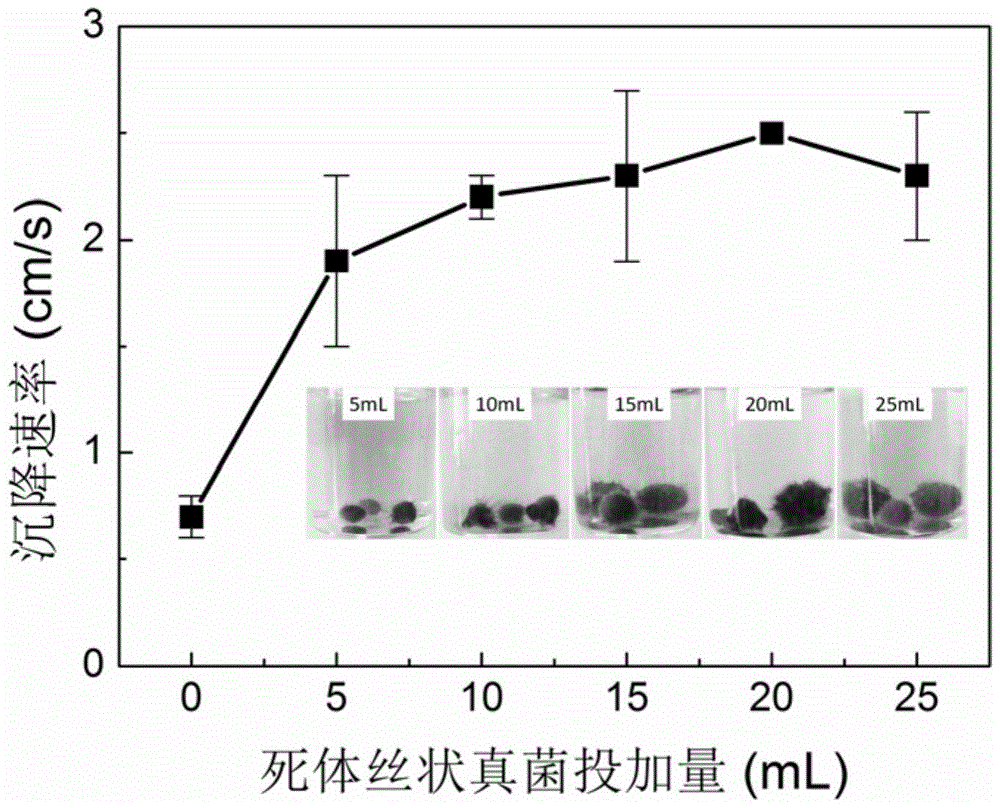

[0037] A reaction beaker was placed on a constant temperature magnetic stirrer, and 100 mL of a suspension containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com