Combustible gas safety monitoring and controlling device and method for steel slag waste heat pressure hot disintegration

A hot stuffiness and waste heat technology, applied in the field of steel slag waste heat pressurized hot stuffy combustible gas safety prevention and control device, can solve safety hazards and other problems, achieve the effect of safety prevention and control, eliminate safety hazards, and simple installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

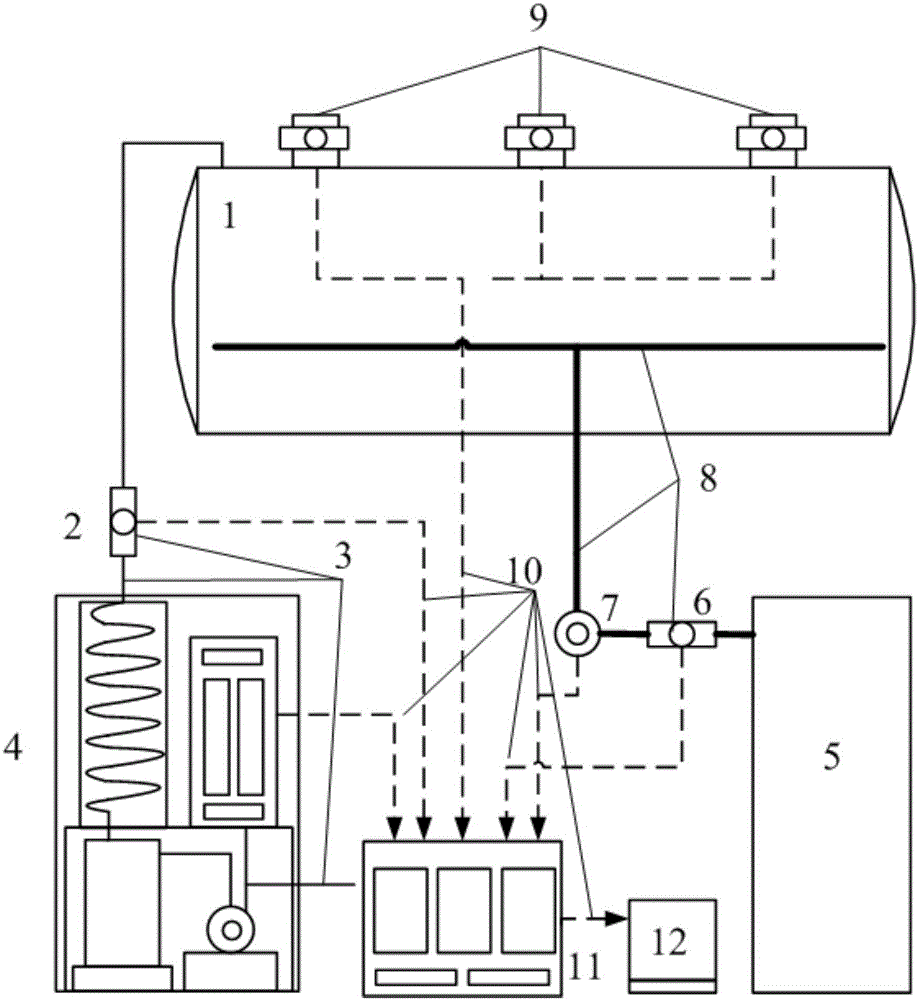

[0026] A safety prevention and control device for hot stuffy combustible gas with steel slag waste heat is attached figure 1 As shown, a safety prevention and control device for autoclavable stuffy combustible gas with residual heat of steel slag, including: autoclavable stuffy tank 1, air induction valve 2, air induction pipe 3, gas analyzer 4, nitrogen gas storage tank 5, nitrogen valve 6. Nitrogen flow meter 7, nitrogen pipe 8, exhaust valve 9, data transmission line 10, PLC control system 11, and calculation and display system 12. In the device, the air induction pipe 3 includes the first air induction pipe, the second air induction pipe and the third air induction pipe; The outlet end of the gas analyzer is connected to the gas analyzer 4 through the second air induction pipe 3, and the extracted gas is discharged from the gas analyzer 4 through the third air induction pipe 3. Nitrogen pipe 8 comprises first nitrogen pipe, the second nitrogen pipe, the 3rd nitrogen pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com