Elastic sleeper and production method thereof

A sleeper, elastic technology, applied in the field of elastic sleeper and its manufacturing, can solve the problem of detachment of elastic pad and sleeper body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Batching the concrete composition, wherein the weight ratio of cement, mineral powder, water, sand, stones and water reducer is 391:69:133:633:1287:3.68, and the total weight of the concrete composition is As a standard, the content of the control sand is 33.0% by weight, and the content of the water reducer is 0.80% by weight. Then the concrete composition after batching is manufactured into a sleeper body, and the flatness of the lower surface of the sleeper body is measured to be +0.8mm.

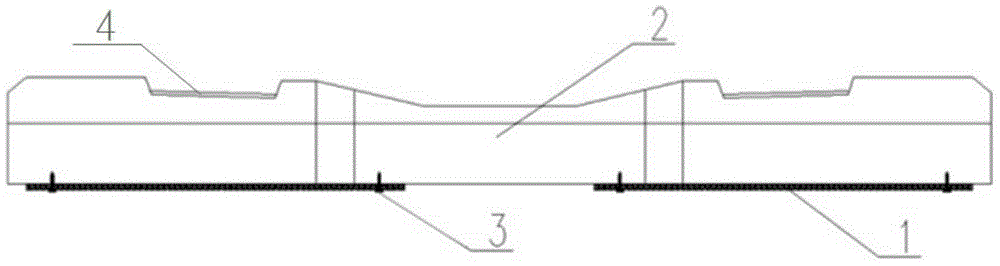

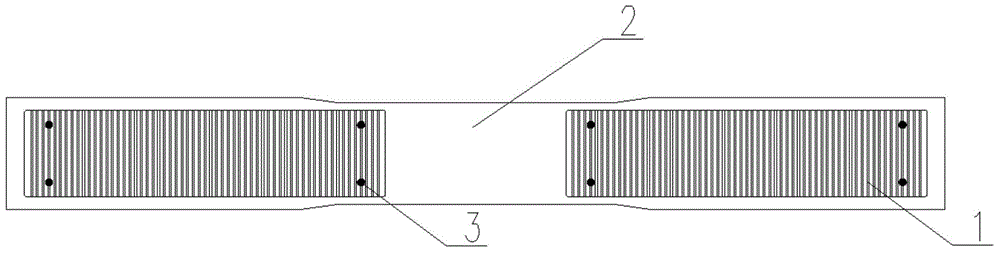

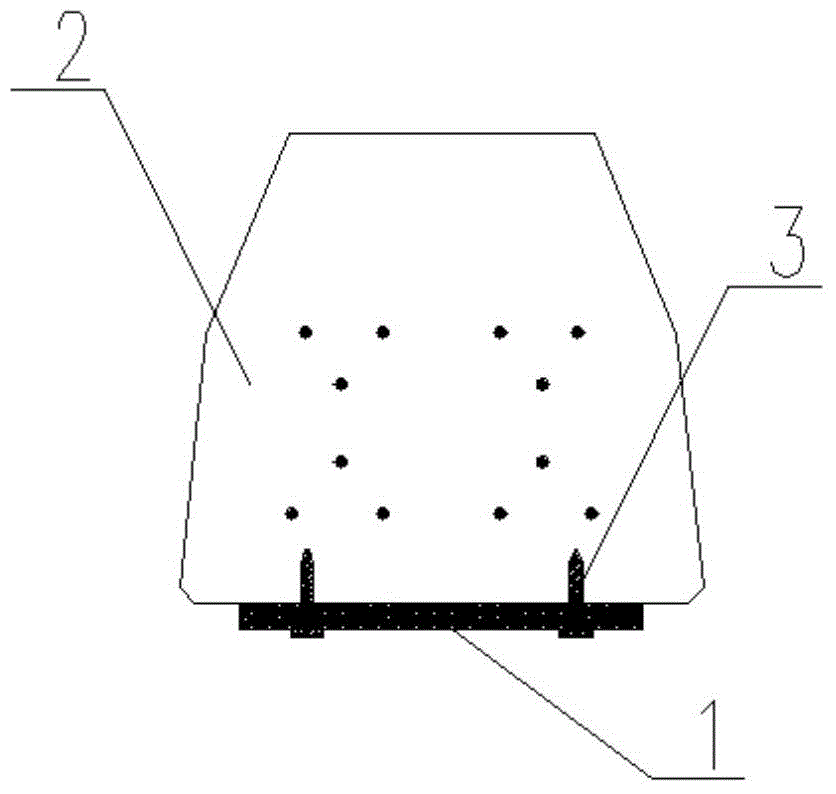

[0049] (2) According to figure 2 In the manner shown, the elastic pad is bonded directly below the rail bearing groove of the sleeper body obtained in step (1) with an adhesive to obtain sample I1, wherein the structure of the elastic pad is as follows Figure 4-Figure 6 As shown, specifically, the elastic layer is made of foam material, the protective layer is made of EPDM rubber mixed with polyester fibers, and the protective layer has a rectangular non-slip structure. Fin...

Embodiment 2

[0053] (1) Batching the concrete composition, wherein the weight ratio of cement, mineral powder, water, sand, stones and water reducer is 386:68:132:630:1280:3.65, and the total weight of the concrete composition is As a standard, the content of the control sand is 33.5% by weight, and the content of the water reducer is 0.83% by weight. Then the concrete composition after batching was manufactured into a sleeper body, and the flatness of the lower surface of the sleeper body was measured to be -0.6mm.

[0054] (2) According to figure 2 In the manner shown, the elastic pad is bonded directly below the rail bearing groove of the sleeper body obtained in step (1) with an adhesive to obtain sample I2, wherein the structure of the elastic pad is as follows Figure 4-Figure 6 As shown, specifically, the elastic layer is made of foam material, the protective layer is made of polyurethane mixed with polyester fiber, and the protective layer has a circular non-slip structure. Fina...

Embodiment 3

[0056] (1) The concrete composition is batched, wherein the weight ratio of cement, mineral powder, water, sand, stones and water reducer is 396:70:134:640:1295:3.75, and the total weight of the concrete composition is As a standard, the content of the control sand is 33.8% by weight, and the content of the water reducer is 0.85% by weight. Then the concrete composition after batching is manufactured into a sleeper body, and the flatness of the lower surface of the sleeper body is measured to be +0.8mm.

[0057] (2) According to figure 2 In the manner shown, the elastic pad is bonded directly below the rail bearing groove of the sleeper body obtained in step (1) with an adhesive to obtain sample I3, wherein the elastic pad has a structure such as Figure 4-Figure 6 As shown, specifically, the elastic layer is made of foam material, the protective layer is made of EPDM rubber mixed with polyurethane and mixed with polyester fiber, and the protective layer has a triangular ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com