A roof steel structure and its construction method

A technology of steel structure and roof, applied in the direction of roof, building components, building structure, etc., can solve the problem that the beam can not bear the reverse load, etc., achieve the effect of light weight, overcome technical defects and save installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

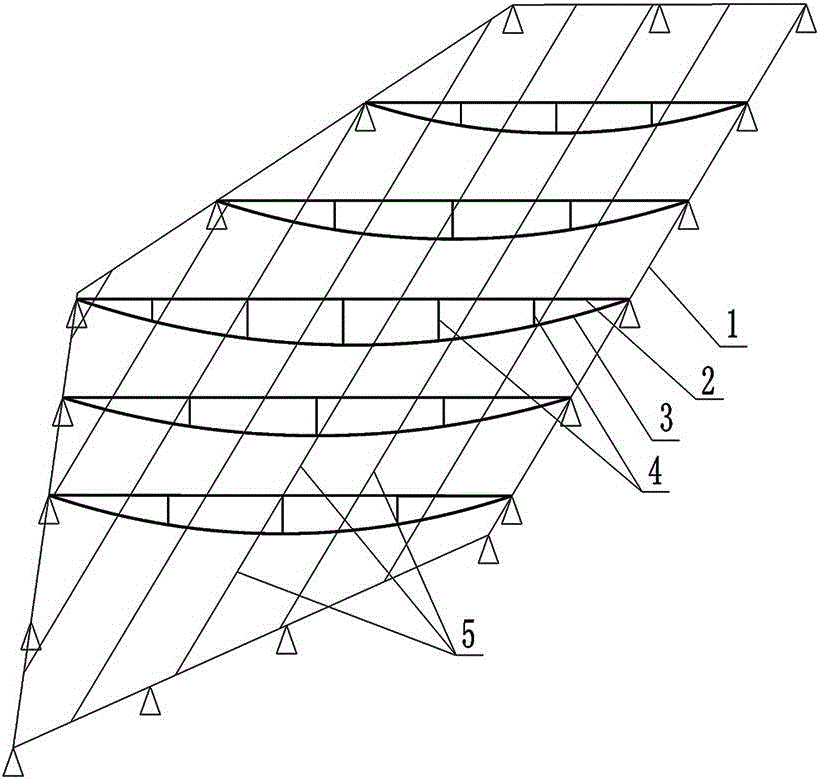

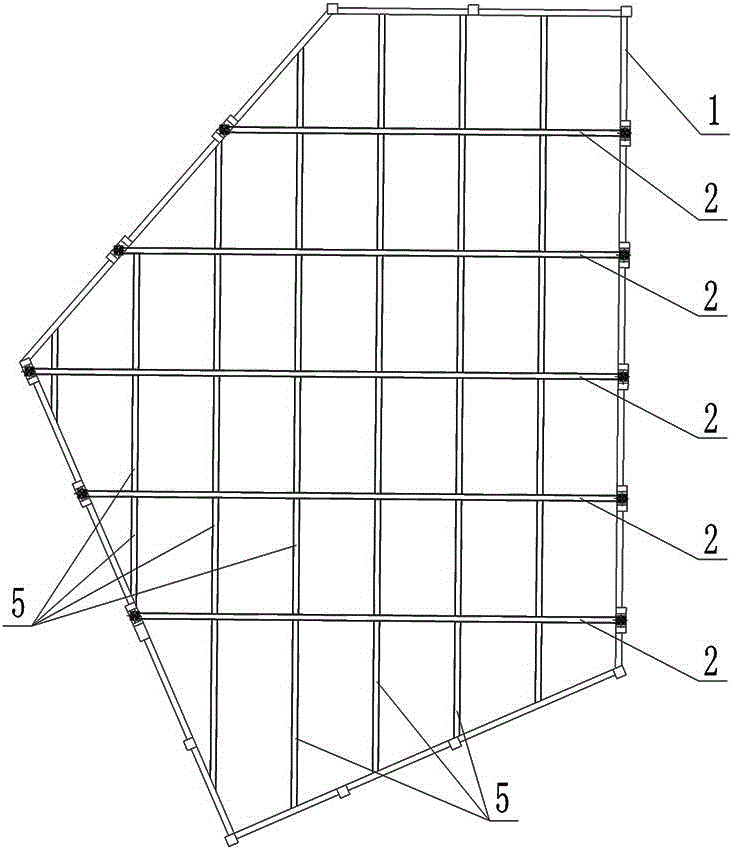

[0047] Such as figure 1 , figure 2 As shown, a roof steel structure, a roof steel structure, including a concrete frame 1 enclosing the outline of the roof, a plurality of horizontally arranged main beams and a plurality of longitudinally arranged secondary beams arranged in the concrete frame 1 , the concrete frame 1 is surrounded by a plurality of concrete beams extending in different directions. The concrete frame 1 is an arbitrary polygon, and each concrete beam is a side of the polygon. beam,

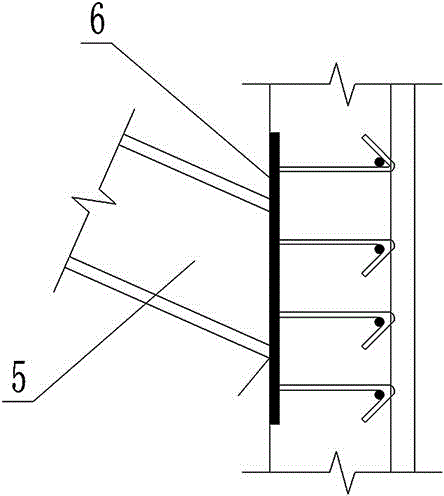

[0048] The main girder is a string beam composed of a rigid beam 2, a lower string 3 and a support rod 4, the two ends of the lower string 3 are fixedly connected to the two ends of the rigid beam 2, and the lower part of the rigid beam 2 is provided with a support rod 4 at intervals, One end of the support rod 4 is connected with the rigid beam 2, and the other end of the support rod 4 is connected with the lower string 3,

[0049] The concrete frame 1 is fixedly provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com