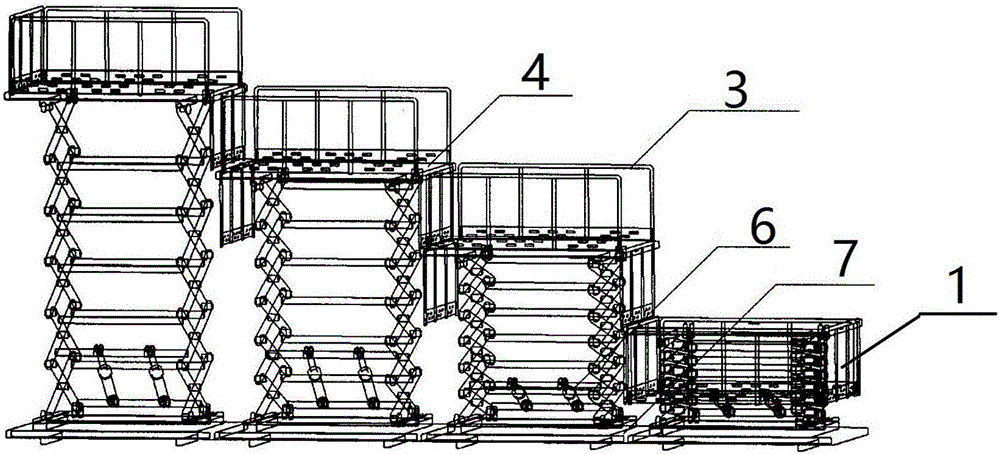

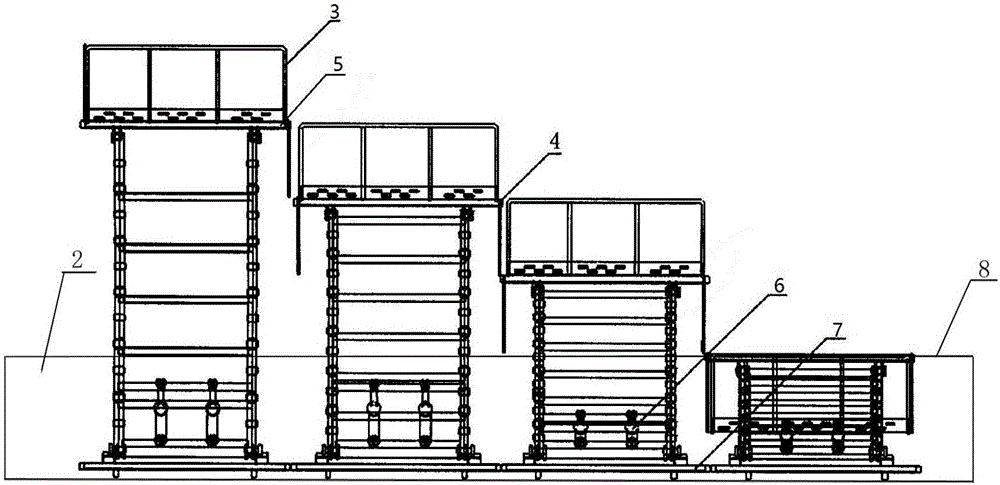

Modularized intelligent reconstruction general work stair platform

A technology for aircraft assembly and working ladder, which is applied in the directions of stairs, mobile staircases, building structures, etc., can solve the problems of a large number of special work ladders, a large storage area for work ladders, and a long aircraft assembly production cycle. The effect of reducing the number of manufacturing, reducing the manufacturing cost, and shortening the production preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

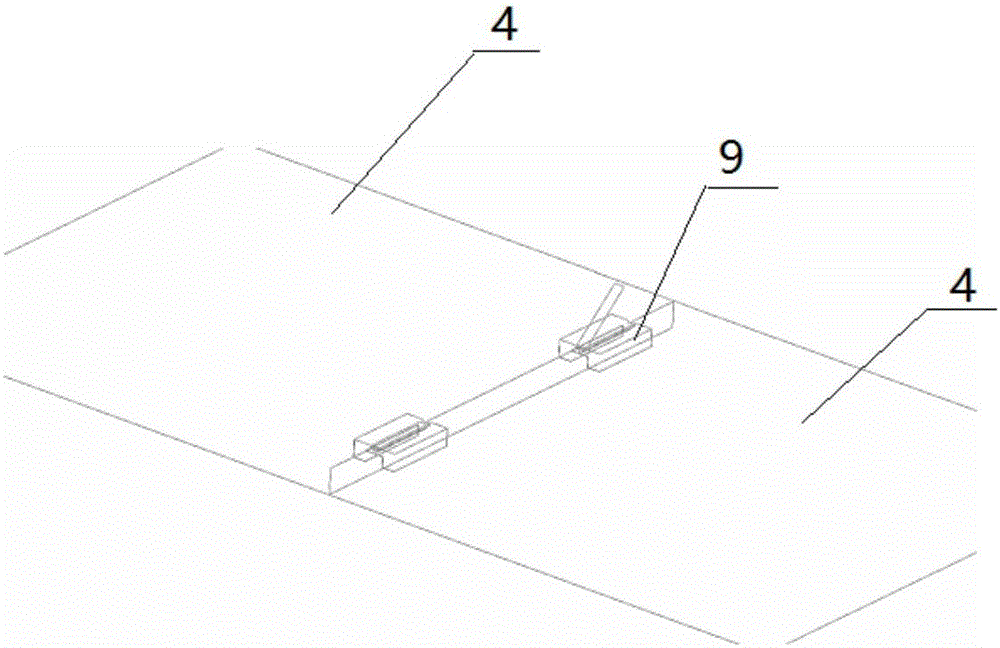

Method used

Image

Examples

Embodiment

[0039] Taking the assembly of the fuselage section in a passenger aircraft as an example, the fuselage section is transported to the work area by an AGV.

[0040] First, determine the digital model of the AGV car and the fuselage section.

[0041] Then, under the positional reconfiguration adjustment module of the program system, input the digital model of the AGV car and the fuselage section, and set the coordinates of the digital model to make it reach the theoretical position, and set the working area and working method.

[0042] Secondly, the simulation analysis and verification of the arbitrary setting of the working ladder is carried out, and the influence of interference and collision is eliminated according to the simulation results, and the control system generates the numerical control code according to the simulation results.

[0043] Finally, the fuselage barrel section is transported to the designated work area by the AGV vehicle, and the AGV vehicle is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com