High temperature and high pressure gate valve

A high-temperature and high-pressure, gate valve technology, applied in sliding valves, valve details, valve devices, etc., can solve the problem that high-temperature gate valves cannot meet high-pressure working conditions on site, and achieve the effect of reducing temperature, prolonging service life, and facilitating on-site installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

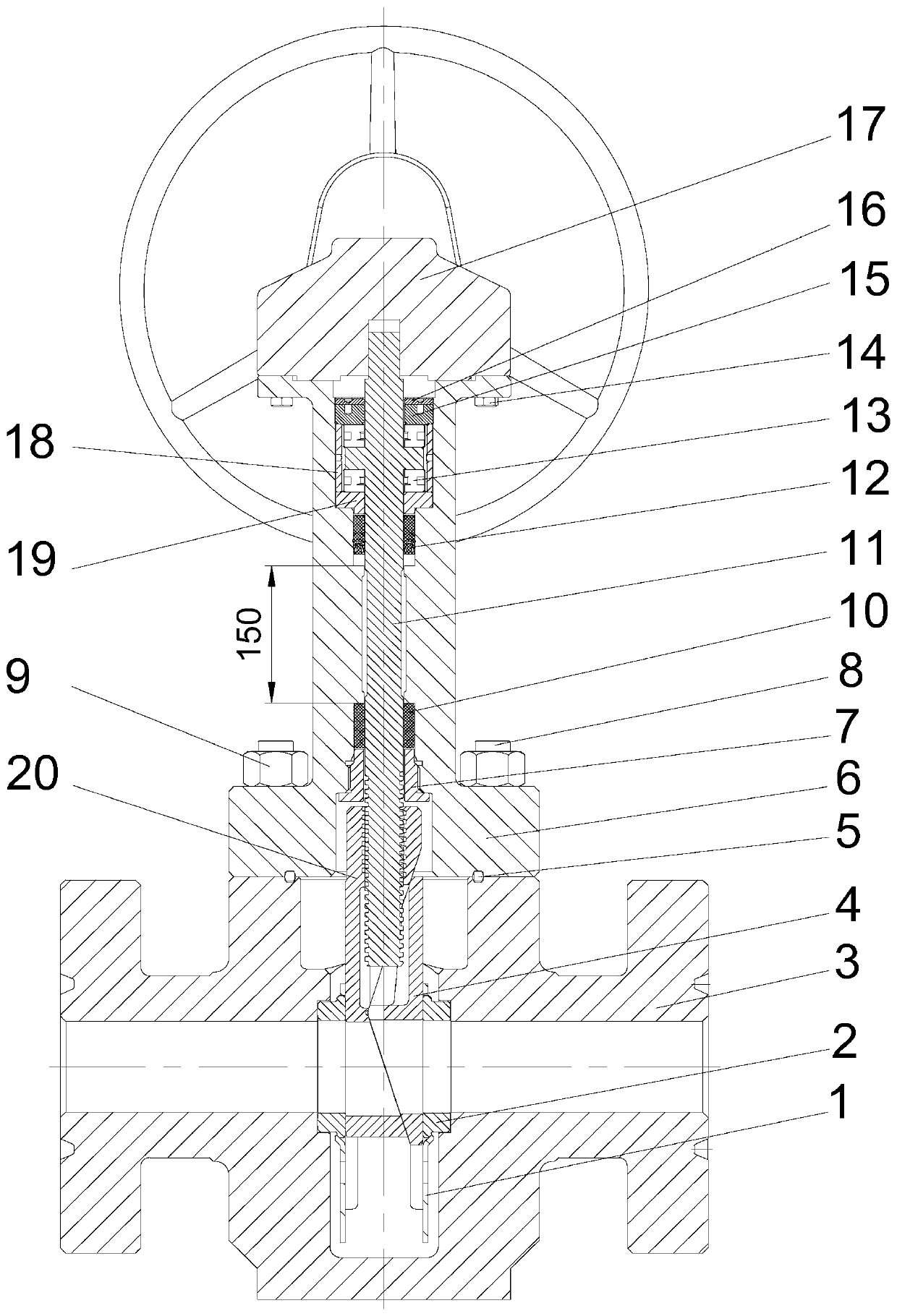

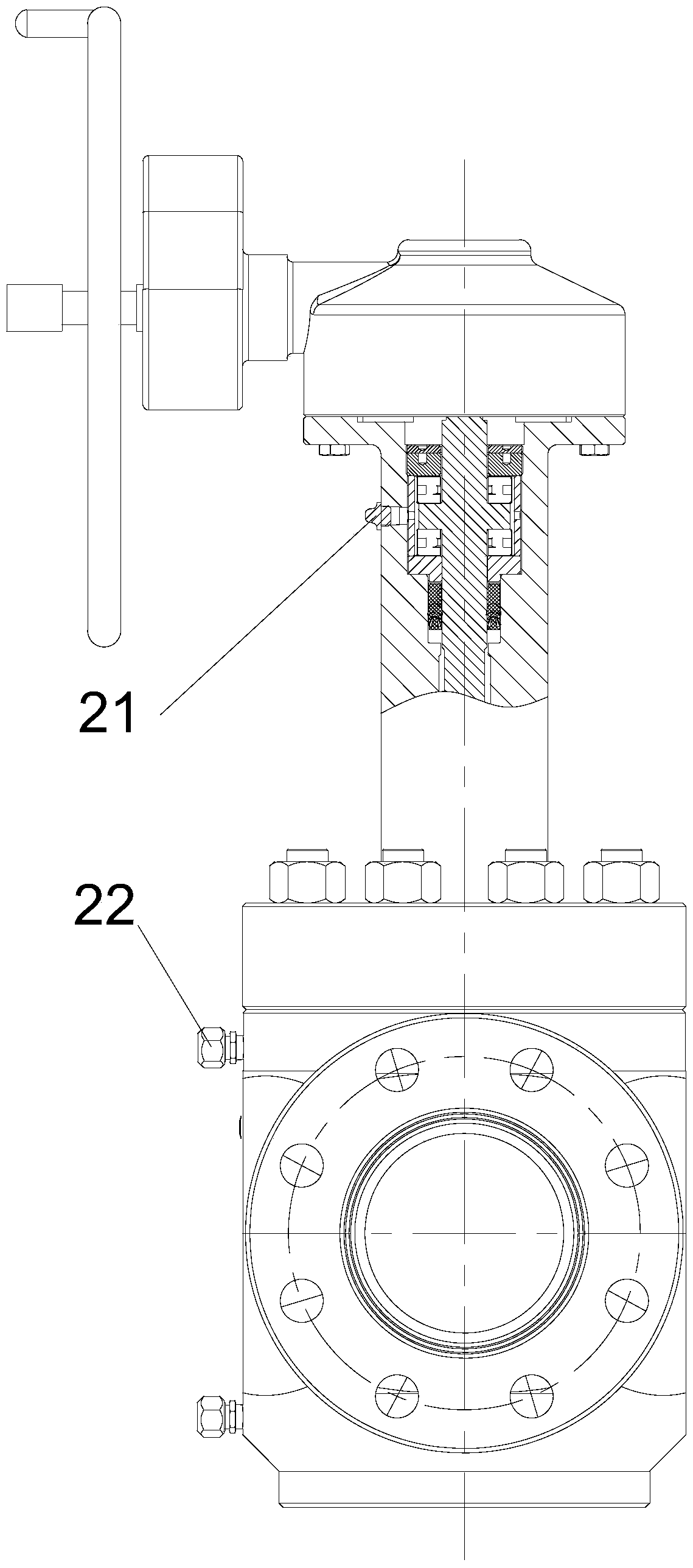

[0025] see Figures 1 to 3 , a high temperature and high pressure valve, a high temperature and high pressure gate valve, comprising a valve body 2, a valve seat 3, a gate plate 4, a valve cover 6, a valve stem 11 and a gear box 17 with a hand wheel.

[0026] The middle cavity of the valve body 3 is provided with a seat ring hole, and the valve seat 2 is installed in the seat ring hole with a clearance fit, and the valve seat 2 and the valve body 3 are sealed by metal.

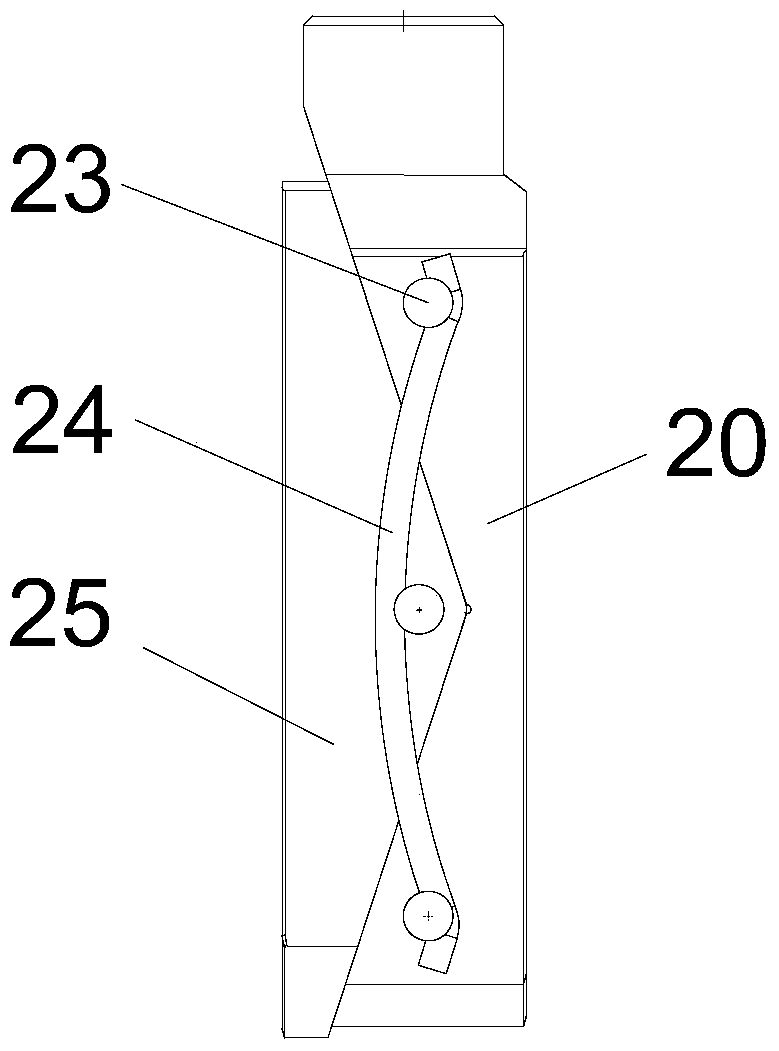

[0027] The guide plate 1 is fixed on the lower end of the valve seat 2 and extends downward. The flashboard 4 includes a main flashboard block 20 and a secondary flashboard block 25. The main flashboard block 20 cooperates with the secondary flashboard block 25 through an inclined surface and an elastic member is connected between the main flashboard block 20 and the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com