An uninterrupted gas supply device on a circular production line

A gas supply device and production line technology, which can be applied to equipment loaded into pressure vessels, gas/liquid distribution and storage, container discharge methods, etc. , reduce costs, avoid the effect of mobile synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

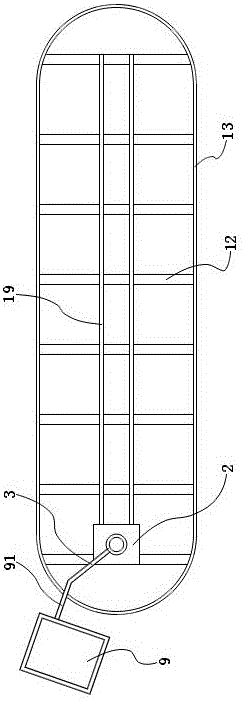

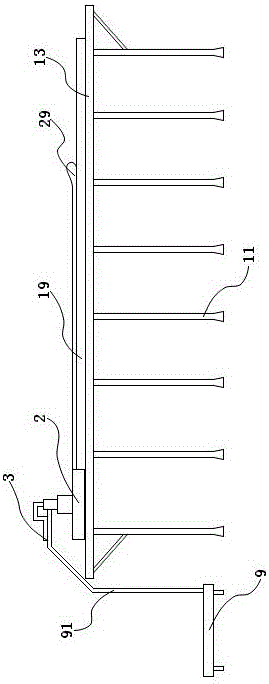

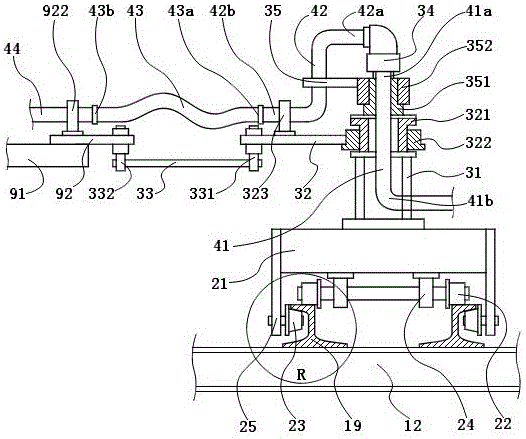

[0021] like figure 1 , figure 2 As shown, an uninterrupted gas supply device on an annular production line includes an annular frame and a production trolley 9 . The ring frame includes a column 11 , a beam 12 and a ring edge 13 . Column 11 is vertically installed. The beam 12 is installed on the top of the column 11 and is horizontal. The ring edge 13 is mounted on the end of the beam 12 to form a ring edge structure. The central frame of the ring frame is provided with a guide rail 19 . The guide rail 19 is a linear guide rail and is installed on the beam 12 . Air supply car 2 is provided on the guide rail 19 . The air supply vehicle 2 can move along the guide rail 19 . There are a plurality of production trolleys 9, which can move in a circular direction around the ring frame. One of the production trolleys 9 is equipped with an air supply connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com