Compact Intermediate Fluid Vaporizer

A gasifier and fluid type technology, which is applied in the field of compact intermediate fluid type gasifiers, can solve the problems of large space and achieve the effect of small footprint, compact structure and high gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

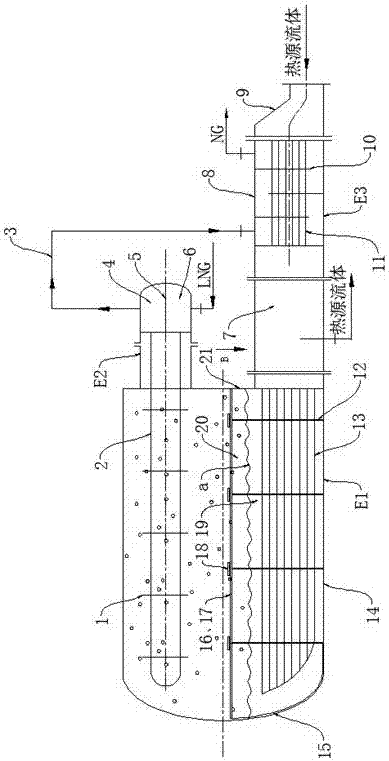

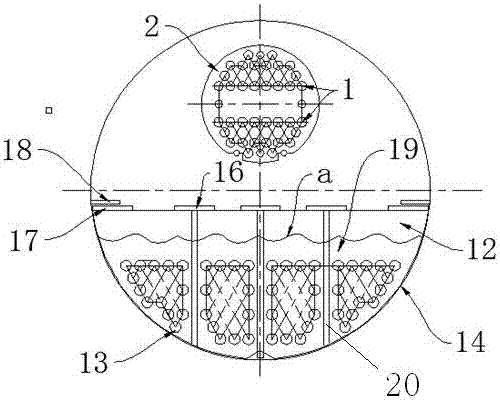

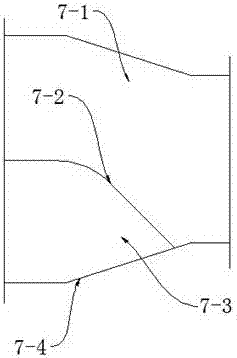

[0026] Such as Figure 1-5 shown.

[0027] A compact intermediate fluid vaporizer, which consists of three parts, the first part is heat exchanged by the heat source fluid and the intermediate heat transfer fluid to evaporate the intermediate heat transfer fluid, that is, the intermediate heat transfer fluid evaporation section E1, by the second Two heat source tube bundles 13 are realized; the second part is heat exchanged by the intermediate heat transfer fluid and LNG, the intermediate heat transfer fluid is condensed, and the LNG is gasified, that is, the gasification section E2 is realized by the LNG tube bundle 2; the third part is The gasified natural gas exchanges heat with the heat source fluid to superheat the natural gas to a certain required temperature for output, that is, the superheating section E3 is realized by the first heat source tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com