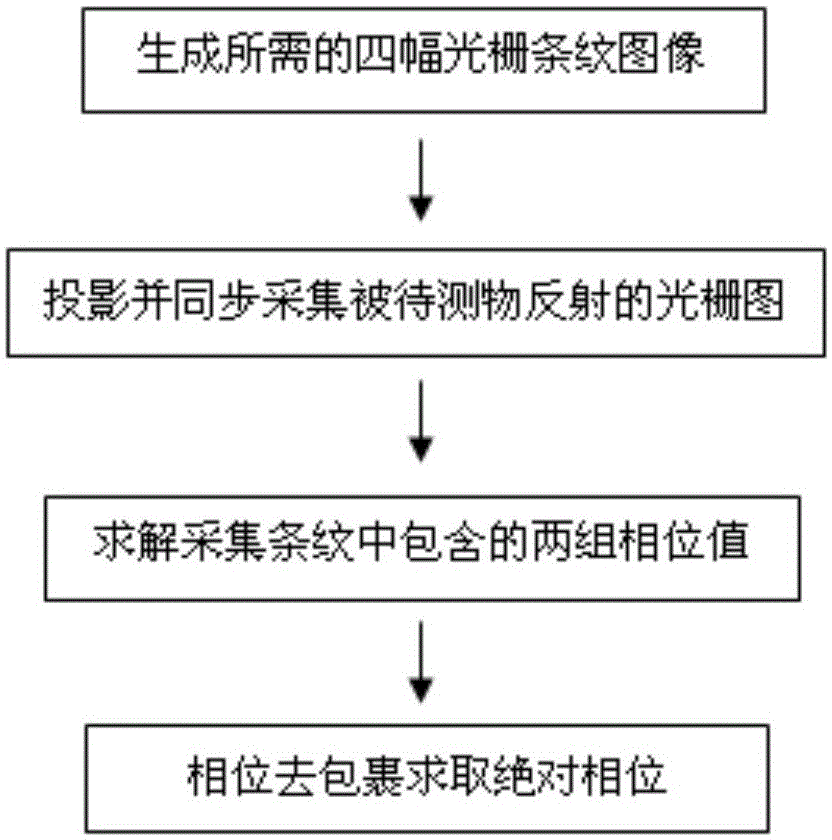

Grating strip phase solving method used for three-dimensional measurement

A grating fringe and phase solution technology, which is applied in the field of optical measurement, can solve problems such as inapplicability, long measurement period, and sensitive object movement, and achieve the effect of reducing the number of fringes and improving the measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

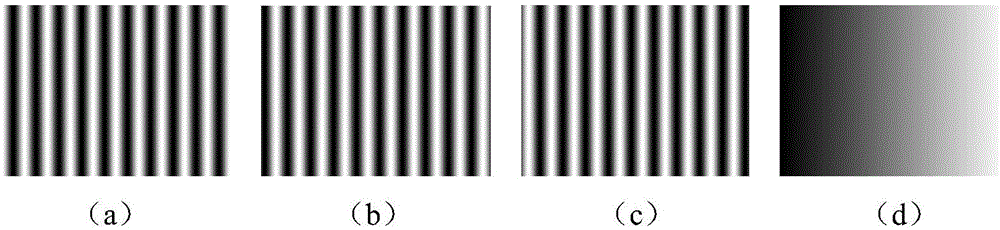

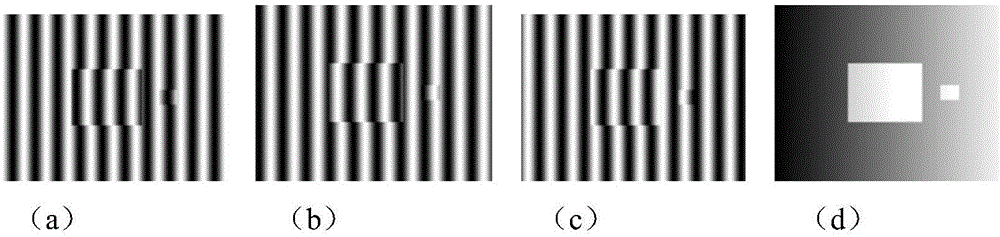

[0055] Generate four grating fringes I according to step one of the present invention 1 ~I 4 , Four grating fringes I 1 ~I 4 Such as figure 2 Shown. figure 2 Where (a) is the first grating fringe I generated 1 , (B) is the second grating stripe I generated 2 , (C) is the generated third grating fringe I 3 , (D) is the fourth grating stripe I generated 4 . When generating four grating fringes I 1 ~I 4 When, the parameters are set as: A(x,y)=B(x,y)=127.5, F is 10, and W is 640. Then simulate, the measured object is two blocks with different heights. According to the second step of the present invention, the four grating stripes are projected onto two squares with different heights, that is, the object under test used in this embodiment. Collect four fringe images modulated on the surface of the object to be measured, such as image 3 As shown, (a) is the first fringe image (b) is the second fringe image (c) is the third stripe image (d) is the fourth fringe image Using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com