Novel calibration plate and calibration method for performing length measurement by using calibration plate

A calibration board and a new type of technology, which are applied to measurement devices, optical devices, instruments, etc., can solve problems such as bottlenecks in optical three-dimensional measurement systems, and achieve the effect of solving errors that cannot be calibrated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is applicable not only to a measurement system for single-frame scanning ("single-view") three-dimensional objects, but also to an optical three-dimensional measurement system for determining a measured object from several different images ("multi-view").

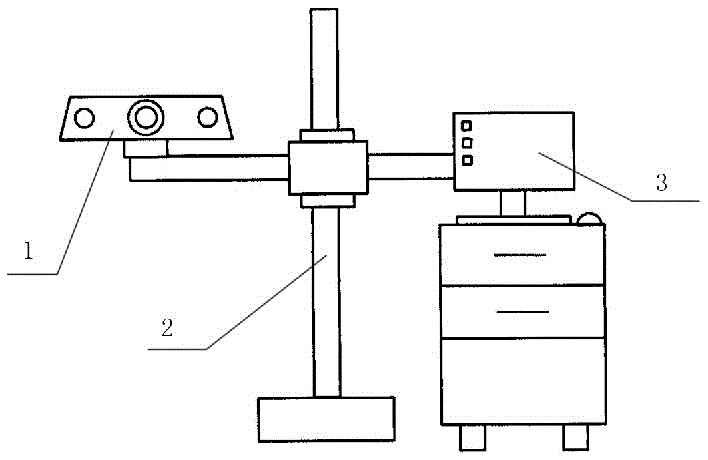

[0017] Optical 3D measurement system based on area scanning such as figure 1 As shown, it is mainly composed of a camera 1, a grating projector 2, a tripod 3, and a calibration board.

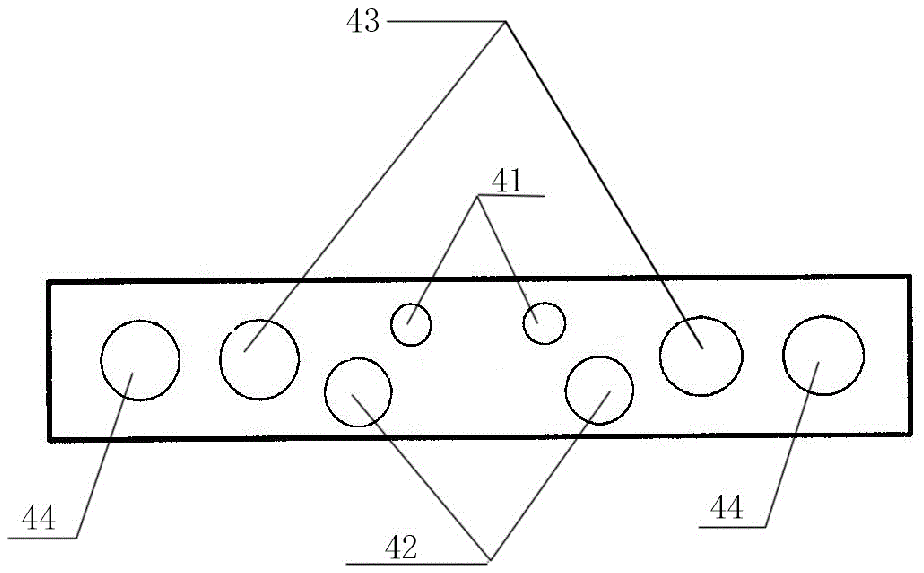

[0018] where the calibration board, such as figure 2 As shown, including calibration board body 41, calibration board 41 length is 1m, and width is 40cm; On calibration board body 41, some positioning balls are set, positioning balls are A, B, C, D four groups, and every group of positioning balls has 2 A group of positioning balls 42 are symmetrically arranged on both sides of the vertical center line of the calibration plate, and the ball diameter is 50mm, and the distance between the group A positioning ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com