Wood floor flatness detection device

A detection device and flatness technology, applied in the direction of measuring devices, instruments, etc., can solve problems affecting product sales, inaccurate judgment, economic loss, etc., and achieve the effect of increasing sales, high detection efficiency, and stable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

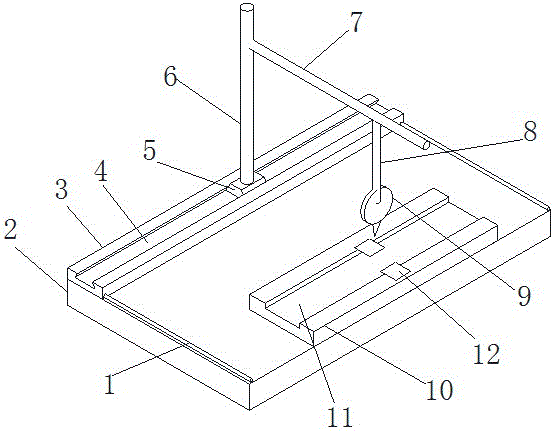

[0010] Example. Wooden floor flatness detection device, constituted as figure 1 As shown, including the base 2, the two ends of the base 2 are provided with guide rods 1, the two guide rods 1 are provided with sliding bars 3, the sliding bars 3 are provided with dovetail grooves 4, and the dovetail grooves 4 are provided with sliding blocks 5 , the sliding block 5 is fixed with a vertical bar 6, the upper end of the vertical bar 6 is connected with a support arm 7, the end of the support arm 7 is provided with a downwardly arranged connecting rod 8, and the lower end of the connecting rod 8 is provided with a deviation meter 9; the base 2 A plank holder 10 is provided on the top, and a plank placement groove 11 is provided on the plank holder 10 .

[0011] Pressing pieces 12 are provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com