Miniature three-degree-of-freedom open airflow gyroscope

An open, degree-of-freedom technology, applied in the direction of steering induction equipment, etc., can solve the problems of large volume, poor consistency, weak ability to drive gas flow, etc., to achieve the effect of wide application field, easy process realization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] Example 1:

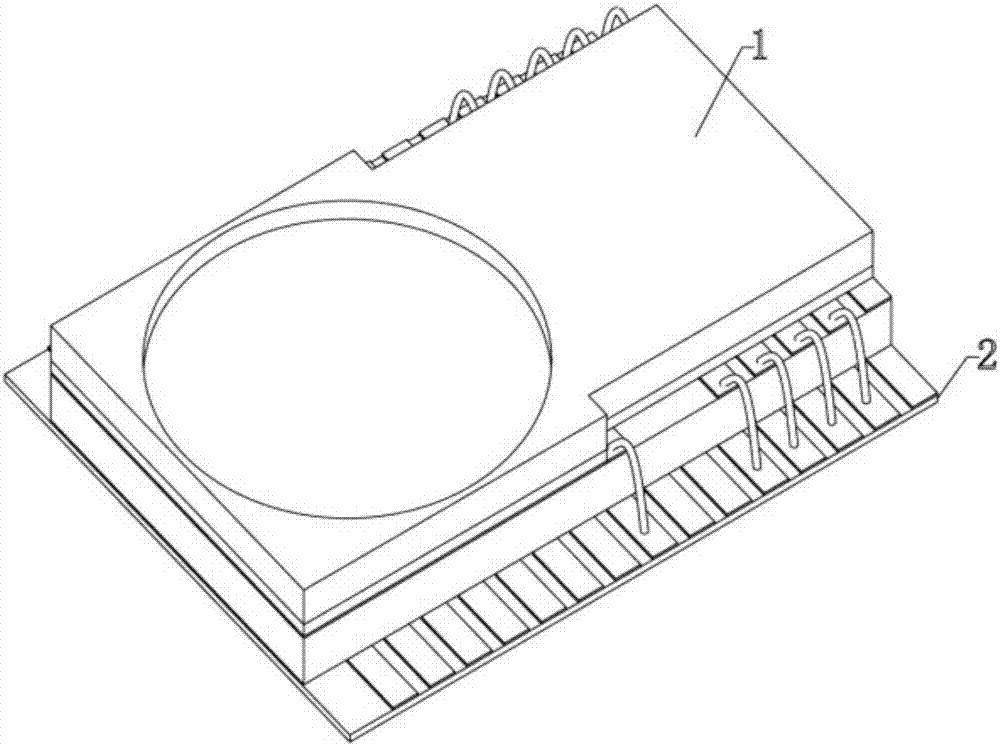

[0035] figure 1 It is a schematic diagram of the three-dimensional structure of the micro three-degree-of-freedom open airflow gyro of this embodiment. As shown in the figure, the miniature three-degree-of-freedom open airflow gyroscope is composed of a three-degree-of-freedom open angular velocity sensor 1 and a PCB circuit board 2, and the two are electrically connected by gold wires.

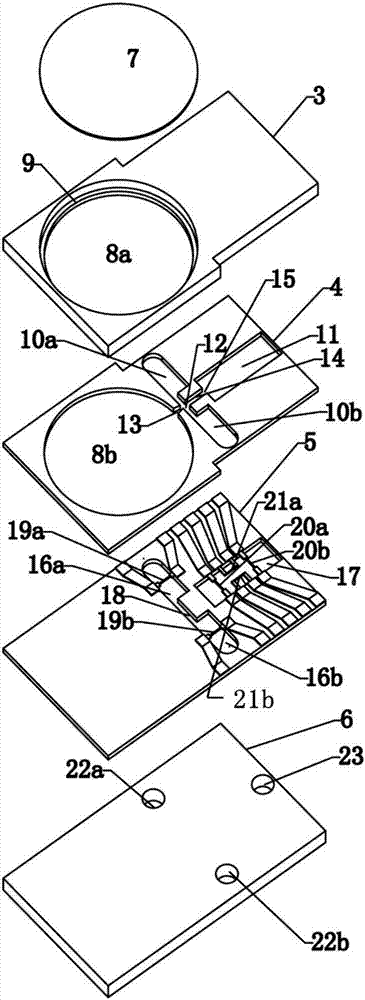

[0036] figure 2 It is a segmented schematic diagram of an open angular velocity sensor 1 with three degrees of freedom. As shown in the figure, the three-degree-of-freedom open angular velocity sensor 1 includes an upper cover plate 3, an upper silicon plate 4, a lower silicon plate 5 and a bottom plate 6. Specifically, it is composed of an upper cover including a piezoelectric ceramic vibrator 7 The board 3, the upper silicon board 4 with the air flow network, the lower silicon board 5 with hot wires on the surface, and the bottom board 6 are bonded together by four-l...

Example Embodiment

[0050] Example 2:

[0051] The present embodiment provides a method for manufacturing the three-degree-of-freedom open angular velocity sensitive element 1, which adopts the mature PMMA high-precision CNC machine tool processing technology and silicon wafer micromachining technology, and the manufacturing process is simple, and the manufacturing process is as follows:

[0052] 1. Fabrication of the upper cover 3 and the bottom plate 6: The PMMA plate with a thickness of 1.5mm is processed by inputting the corresponding graphics designed by a high-precision CNC machine, and a layer of metal electrodes is sputtered on the surface of the steps 9 of the upper cover 3.

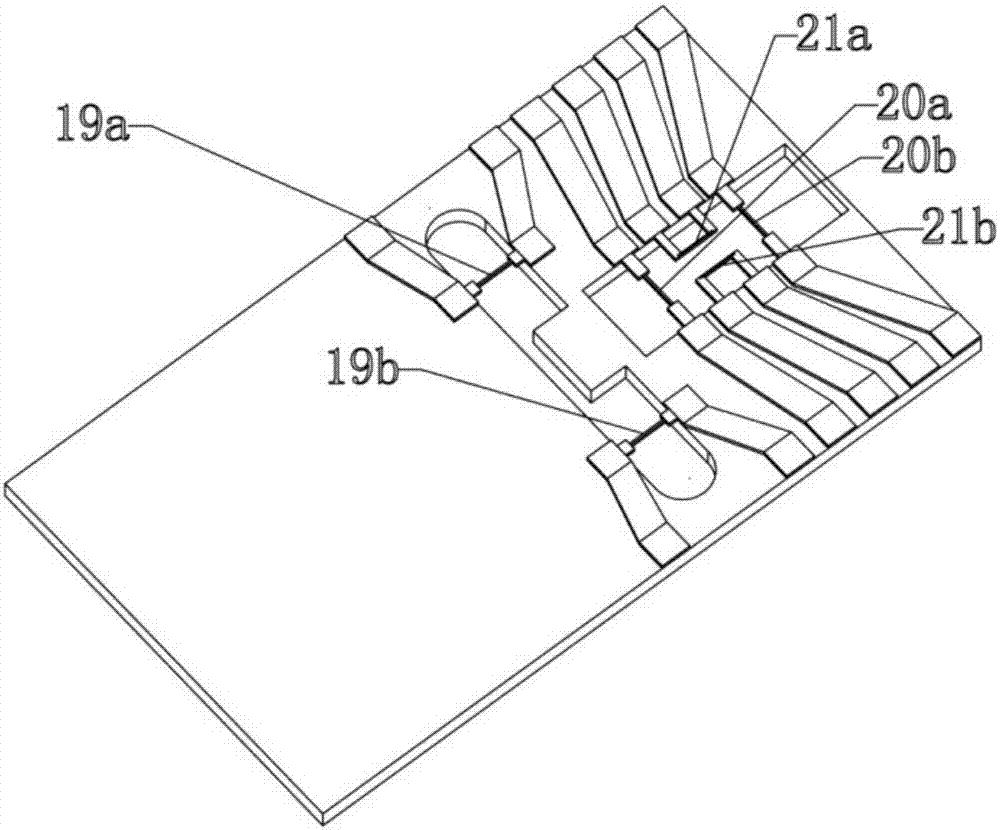

[0053] 2. Production of lower silicon plate 5:

[0054] 1) Epitaxial device layer on insulating silicon wafer and thermal oxidation to form SiO 2 , the sensitive metal layer is formed by sputtering metal W, and the electrode layer is formed by sputtering aluminum.

[0055] 2) The aluminum electrodes and pads are ...

Example Embodiment

[0067] Example 3:

[0068] like Figure 4 As shown, there is an angular velocity input Ω in the Z-axis direction z , due to the principle of Coriolis force, the air flow ejected from the nozzle 15 will be deflected, thereby causing opposite cooling effects on the two oppositely parallel heating lines 21a and 21b in the outlet sensitive chamber 26 . If the angular velocity Ω is input in the X-axis direction X, due to the principle of Coriolis force, the airflow drawn from the two inlets 22a and 22b into the inlet sensitive chambers 25a and 25b reaches the two oppositely parallel hot lines 19a and 19b in the inlet sensitive chambers 25a and 25b in opposite directions. On the plane of the hot lines, The opposite cooling effect can also be formed. If the sensitive angular velocity Ωy is input in the Y-axis direction, due to the principle of Coriolis force, the airflow ejected from the nozzle 15 is deflected in the outlet sensitive chamber 26, and arranged in different positions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com