Dynamic-static double-output rail weighbridge

A track scale, dual output technology, applied in the direction of measuring devices, instruments, weighing, etc., can solve the problems of rising operating costs, inability to output two vertical force signals, static track scale and dynamic track scale cannot be effectively combined into one, etc. Achieve the effect of avoiding tedious work and ensuring high-precision power input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

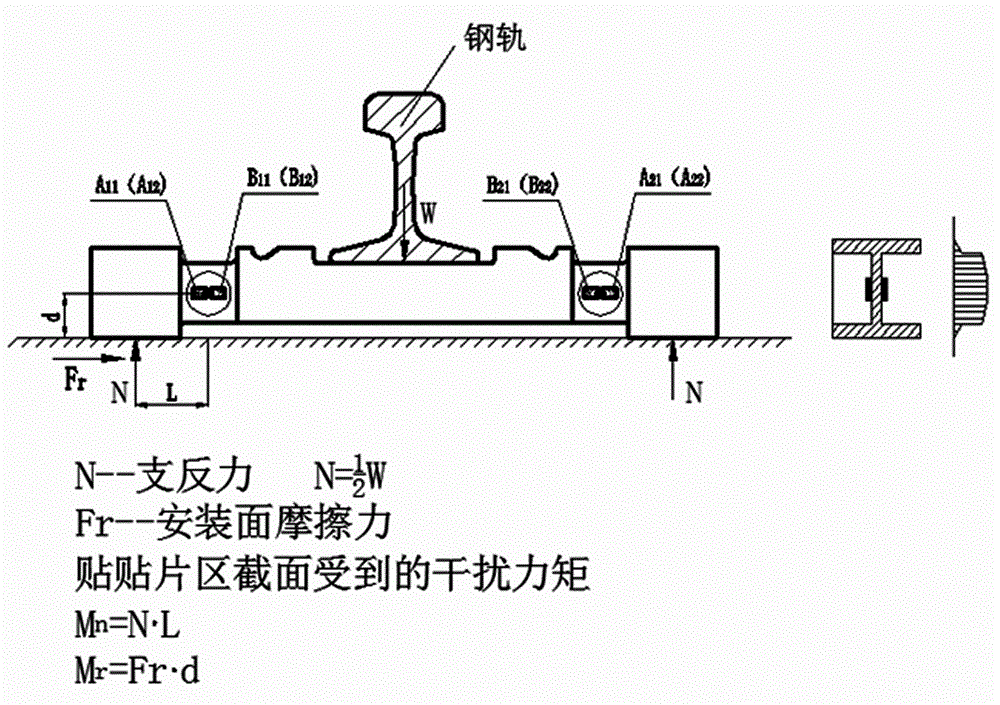

[0022] In the static and dynamic dual-output rail scale according to the present invention, an electronic strain sensor with dual vertical force outputs is adopted, one of which vertical force output is specially used for static rail scale measurement, and the other output is specially used for dynamic rail scale measurement, so as to facilitate Realized the organic combination of static track scale and dynamic track scale.

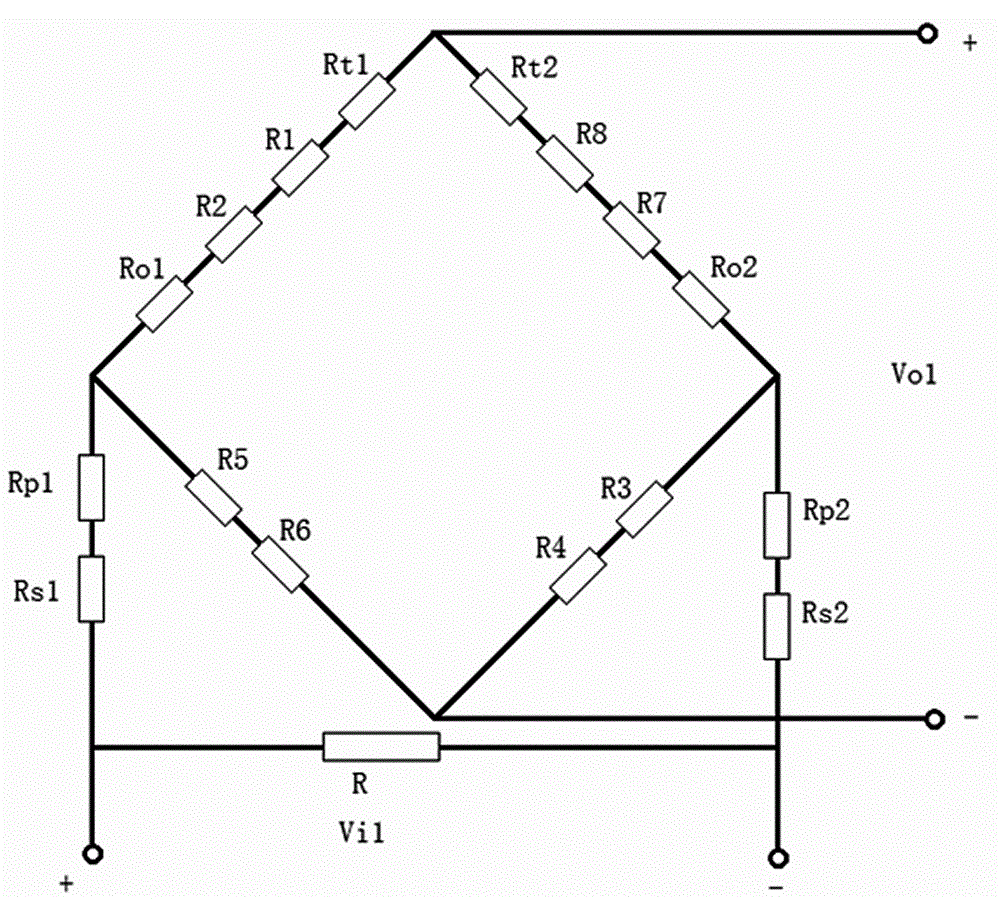

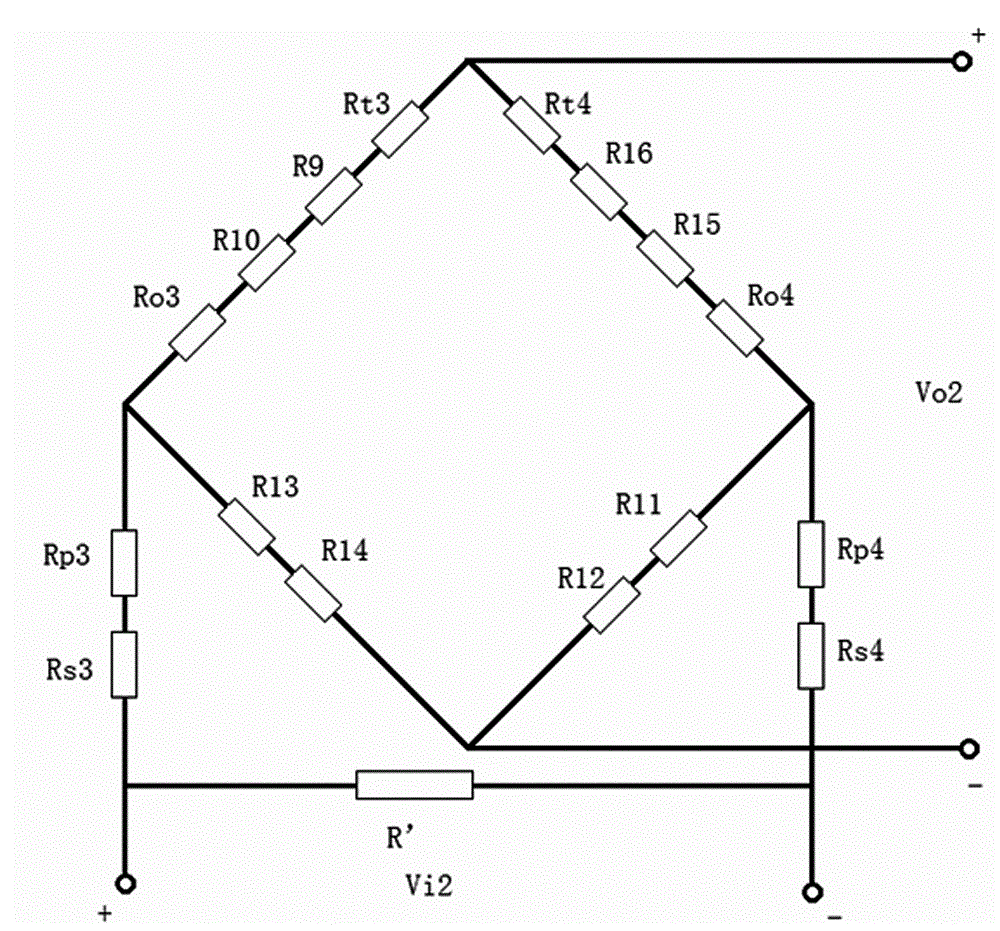

[0023] In the present invention, the resistance strain gauges required by the 2-way Wheatstone bridge circuit are arranged on the bottom surface of the shear strain blind hole web of the elastic body of the same beam type or plate type sensor. Each way alone forms a Wheatstone bridge circuit.

[0024] Such as figure 1 As shown, eight strain gauges with the same resistance value in the first route R1~R8 form a Wheatstone bridge circuit, in which R1~R4 are sheared pullers, R5~R8 are sheared pressure pieces; 2 are used for The temperature zero point compen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com