Turbocharger startup and shutdown impact test device

A technology of turbocharger and impact test, applied in the field of power machinery, can solve the problems of not being able to assess the reliability of the turbocharger of urban vehicles, test the reliability of the turbocharger under the starting and stopping conditions of the turbocharger, etc. Simple, performance-enhancing, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the solutions of the present invention, the two technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

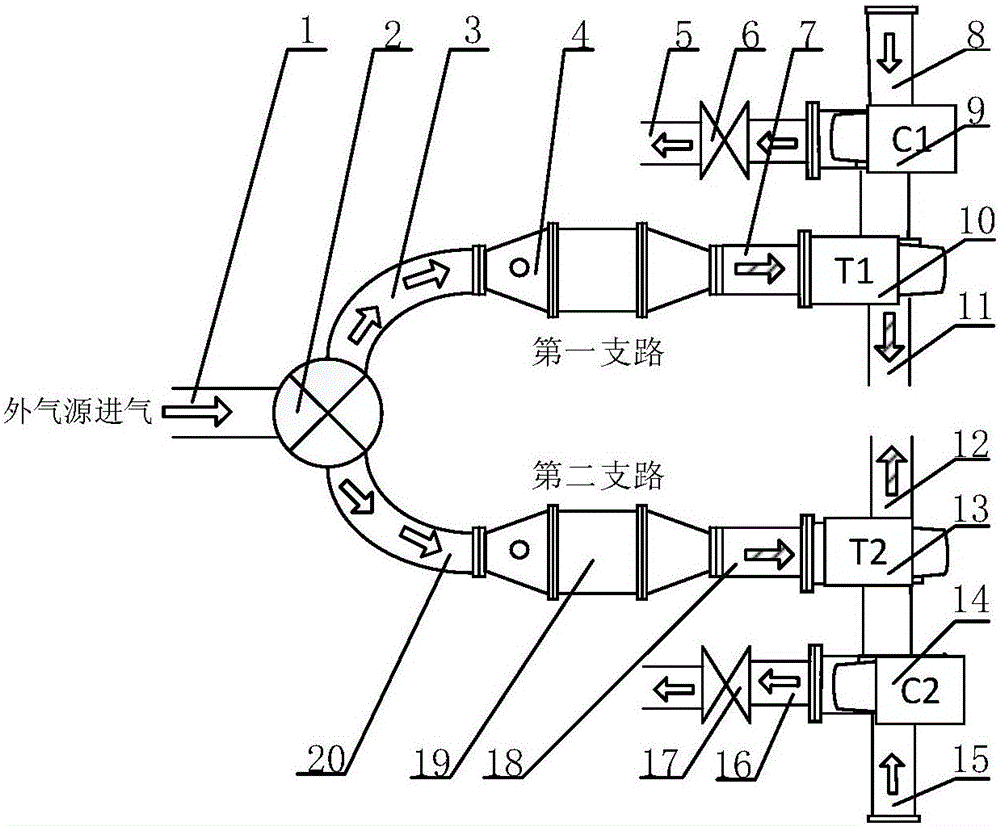

[0018] A turbocharger start-stop shock test device, such as figure 1 As shown, it includes gas source intake pipe 1, gas conversion valve 2, first branch and second branch; the two sets of turbochargers and combustion chambers in the two branches are exactly the same;

[0019] The first turbocharger includes a first compressor 9 and a first turbine 10; the second turbocharger includes a second compressor 14 and a second turbine 13;

[0020] The first branch includes an external air source intake pipe 1, a gas switching valve 2, a first intake pipe 3, a first combustion chamber 4, a first combustion chamber outlet pipe 7, a first turbine 10, and a first turbine outlet pipe 11 , the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com