Inspection tool used on basis of spatial layout

A technology of layout and tooling, applied in the field of test equipment, can solve the problems of non-stop during the smoothing, the process of the smoothing valve cannot be reached, safety accidents, etc., and achieve the effects of cost saving, low manufacturing cost, and convenient and quick use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, not all of them.

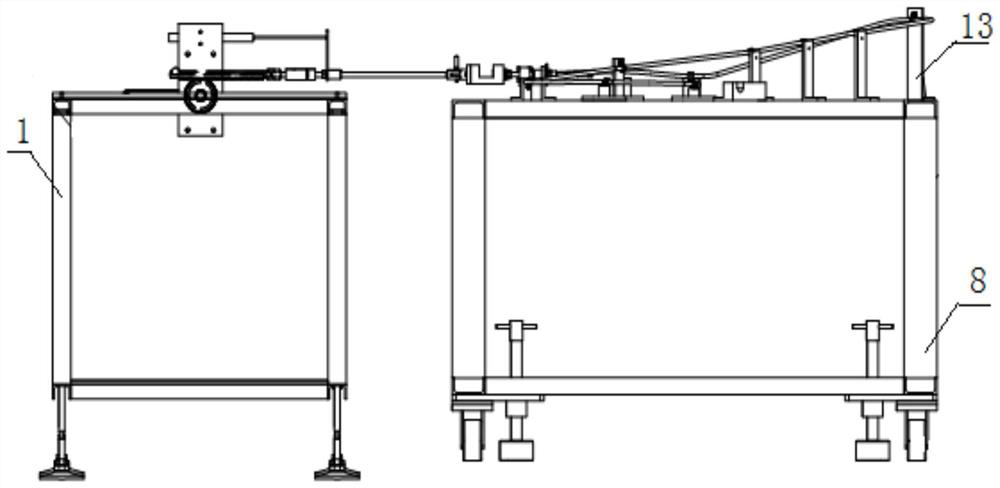

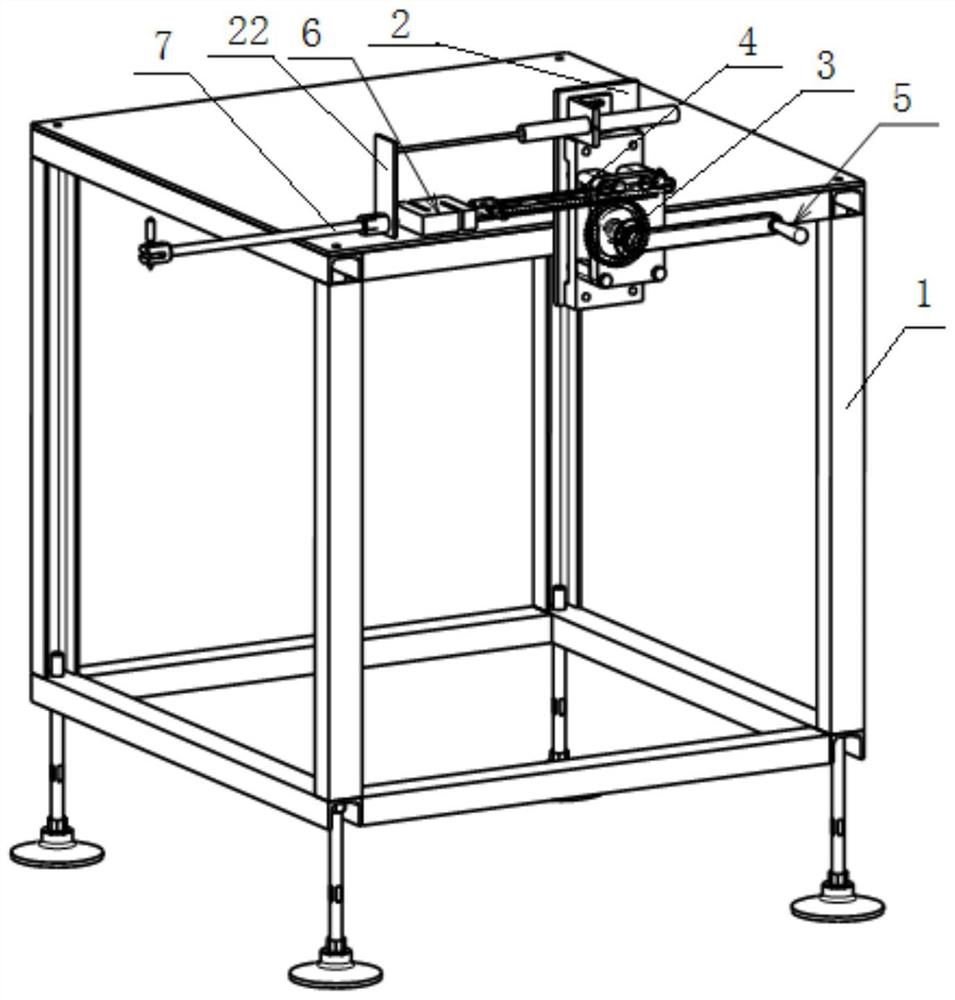

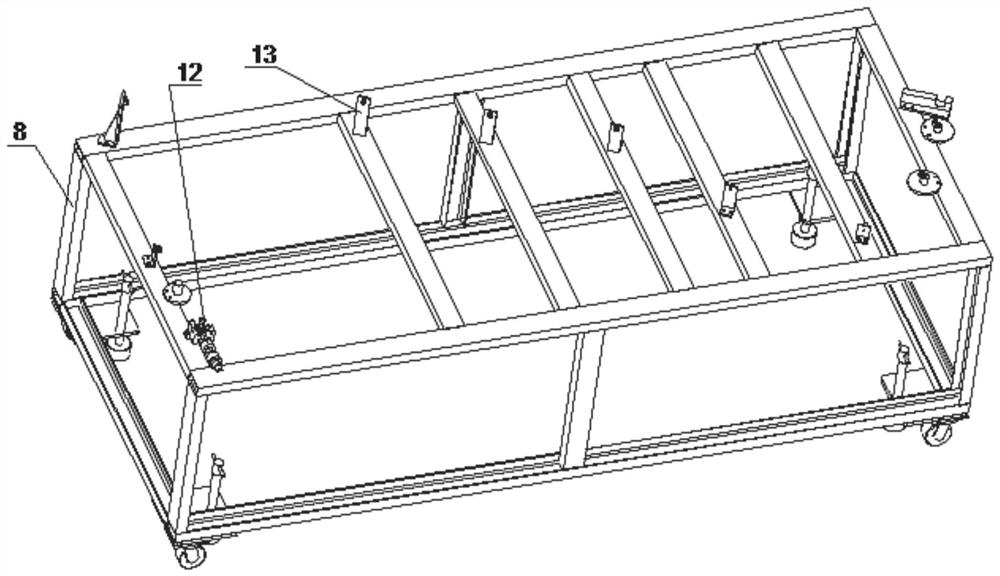

[0023] refer to Figure 1-7 , a kind of inspection tool used on the basis of spatial layout, including a control end test bench 1, a mounting plate 2 is provided on the test bench 1, a rotating shaft is horizontally provided on the mounting plate 2, a gear 3 is sleeved on the rotating shaft, and the rotating shaft is free One side of the gear 3 is connected with a rocker 5, and one side of the gear 3 is provided with a rack 4 meshing with the gear 3. One end of the rack 4 is connected with a push-pull force sensor 6, and the end of the push-pull force sensor 6 is connected with a pull rod 7 away from the rack 4, and the pull rod 7 is far away from One end of the push-pull force sensor 6 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com