Vibration test device in liquid nitrogen temperature zone of cryogenic pressure accumulator for launch vehicle

A technology for vibration testing and launch vehicles, which is applied in vibration testing, measuring devices, and testing of machine/structural components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

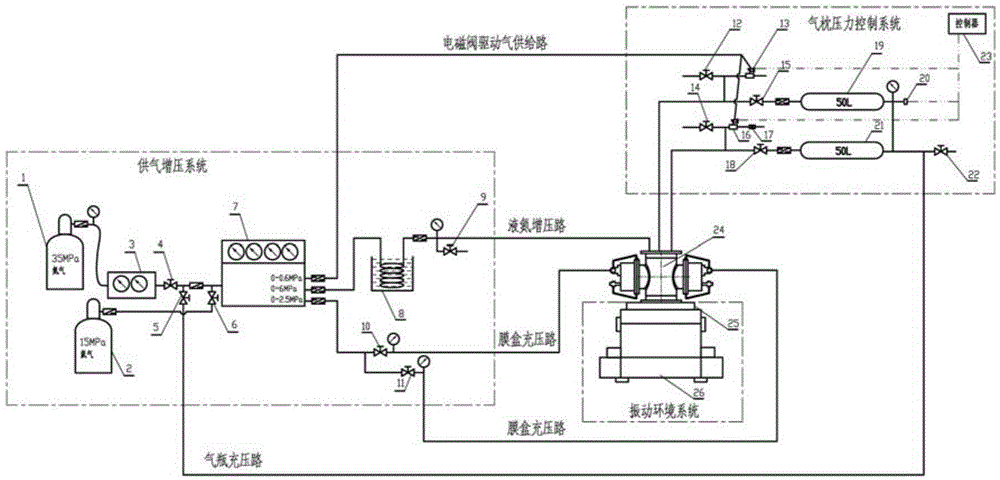

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings. The test object of the present invention is a liquid nitrogen temperature zone vibration test system for a temperature accumulator used in a launch vehicle.

[0015] The test system of the present invention includes an air supply pressurization system, an air pillow pressure control system, and a vibration environment system; the vibration environment system includes a vibration table and a vibration tool; the low-temperature pressure accumulator is installed on the vibration table through the vibration tool; when the test starts , pour liquid nitrogen into the cryogenic pressure accumulator shell, and the gas supply pressurization system fills helium into the bellows of the cryogenic accumulator, so that the pressure in the bellows is consistent with the actual working pressure of the bellows; the air pillow pressure control system A gas cylinder is installed inside, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com