Aircraft large-size panel shear loading apparatus

A large-scale wall plate and loading device technology, applied in the direction of applying stable shear force to test the strength of materials, can solve problems such as the effect of shear uniformity, and achieve the effect of simplified scale and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the aircraft large panel shear loading device according to the scheme of the present invention, below in conjunction with Attached picture A preferred embodiment of the large-scale aircraft panel shear loading device of the present invention is further elaborated.

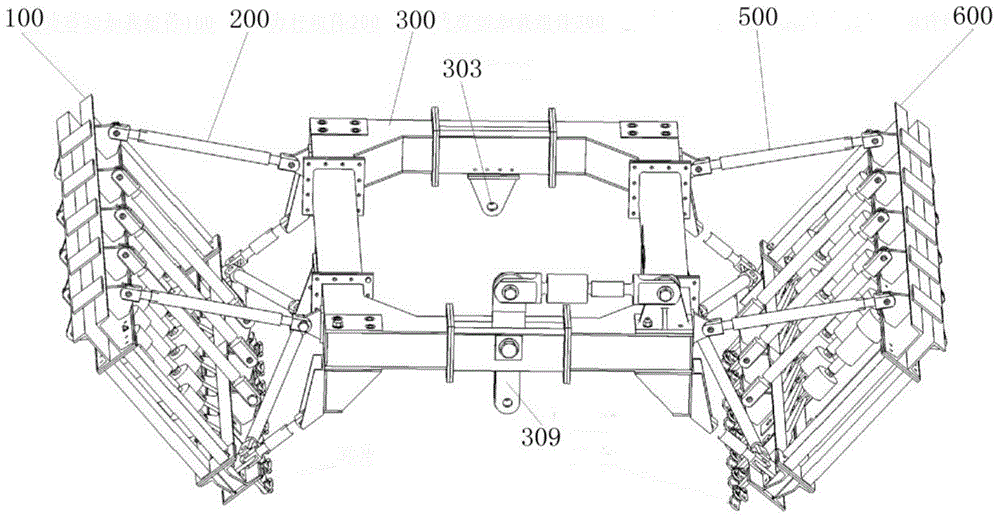

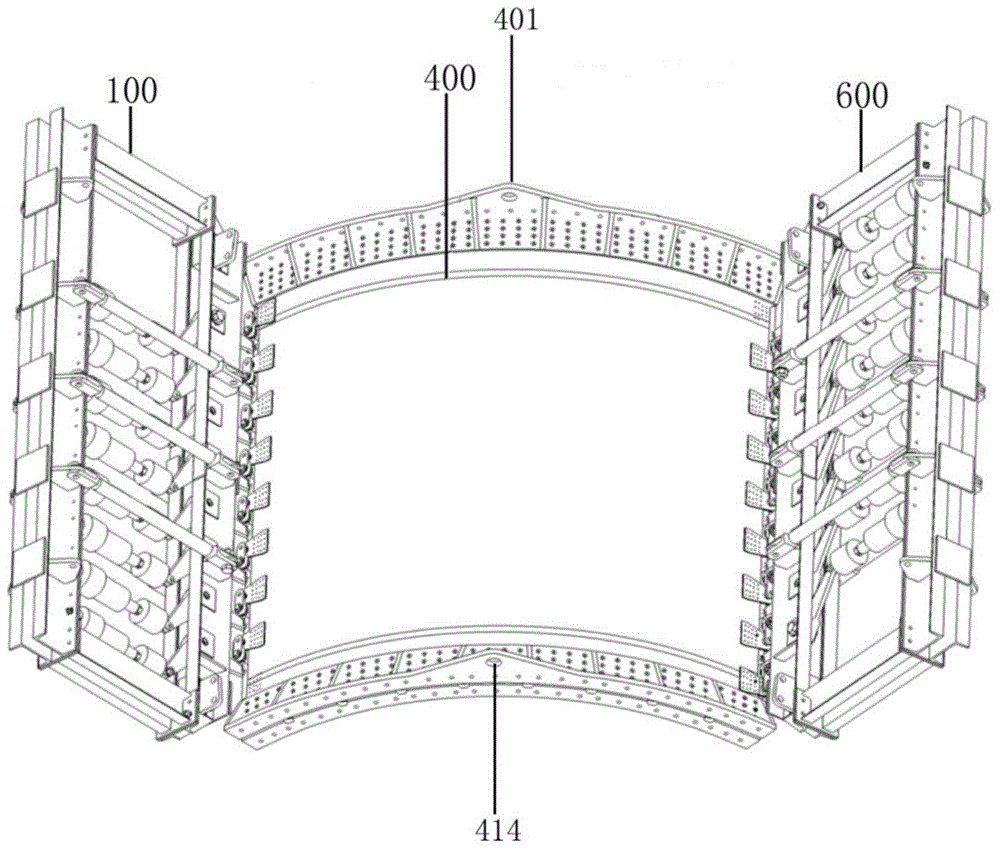

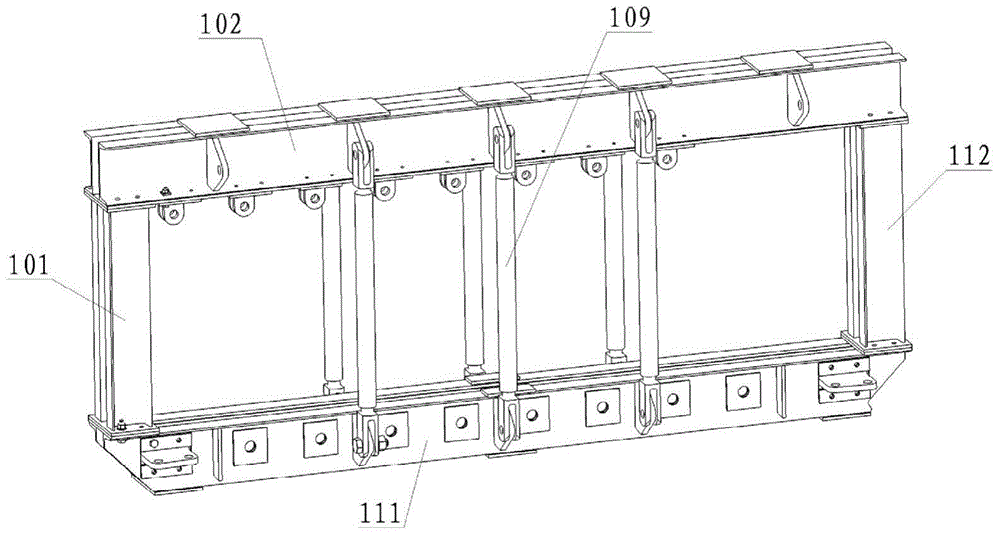

[0023] refer to figure 1 - Figure 7 , The aircraft large panel shear loading device provided by the present invention comprises a first straight-side loading assembly 100, a second straight-side loading assembly 600, a curved-side loading assembly 300, a wall panel test piece 400, a first second force bar assembly 200, a second Two two force bar assemblies 500, wherein, the first straight loading assembly 100 has the same structure as the second straight loading assembly 600 and is antisymmetrically arranged on both sides of the loading frame of the curved loading assembly 300, the first straight loading assembly 100 passes through The first two-force bar assembly 200 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com