A membrane device for catalytic gasoline desulfurization and refining

A catalytic gasoline and membrane device technology, which is applied in the fields of refined hydrocarbon oil and petroleum industry, can solve the problems of gasoline octane loss, difficulty in removal, high equipment investment and operating costs, and achieve less octane loss and process equipment Simple, easy to enlarge and expand the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

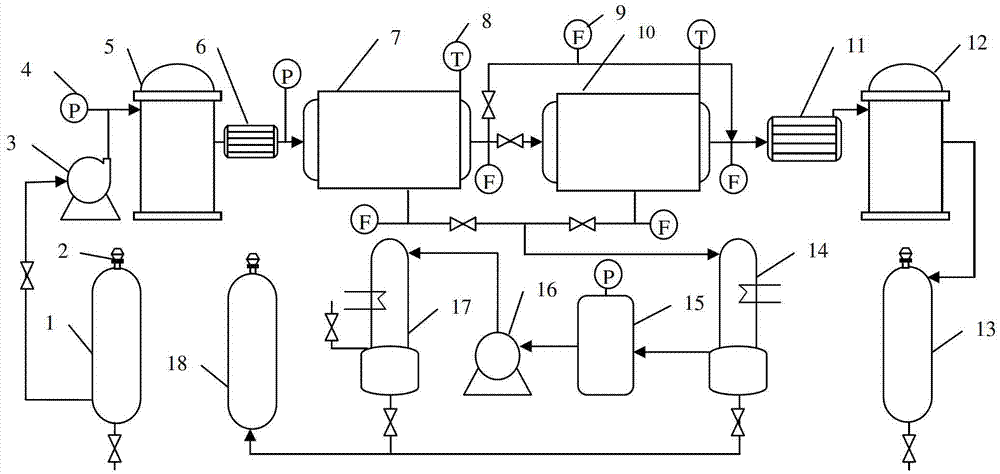

Image

Examples

Embodiment 1

[0016] FCC gasoline with a sulfur content of 500-800μg / g is used as raw material, the feed flow rate is 15L / h, and the raw material is heated to 105-115°C to enter the membrane system. The effective membrane area of each stage of the two-stage membrane separation system is 1m 2 After being treated by the device, the sulfur content of the FCC gasoline can be reduced to 50-100 μg / g, and the octane number loss of the FCC gasoline after desulfurization is below 1%.

Embodiment 2

[0018] FCC gasoline with a sulfur content of 800-1100μg / g is used as raw material, the feed flow rate is 15L / h, and the raw material is heated to 105-115°C to enter the membrane system. The effective membrane area of each stage of the two-stage membrane separation system is 1m 2 After being treated by the device, the sulfur content of the FCC gasoline can be reduced to 150-400 μg / g, and the octane number loss of the FCC gasoline after desulfurization is 1-1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com