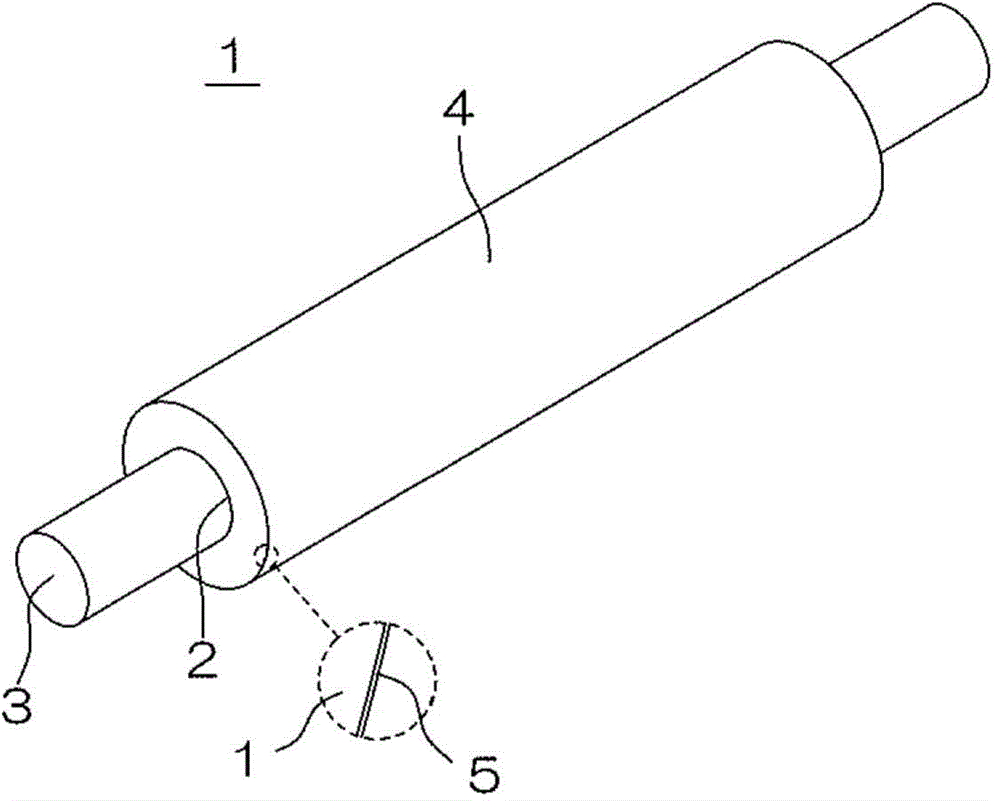

Semiconductive roller

A semi-conductive and rubber-based technology, which is applied in the direction of electrography, electrical recording technology using charge patterns, and equipment for electric recording technology using charge patterns, etc., and can solve problems such as low image density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

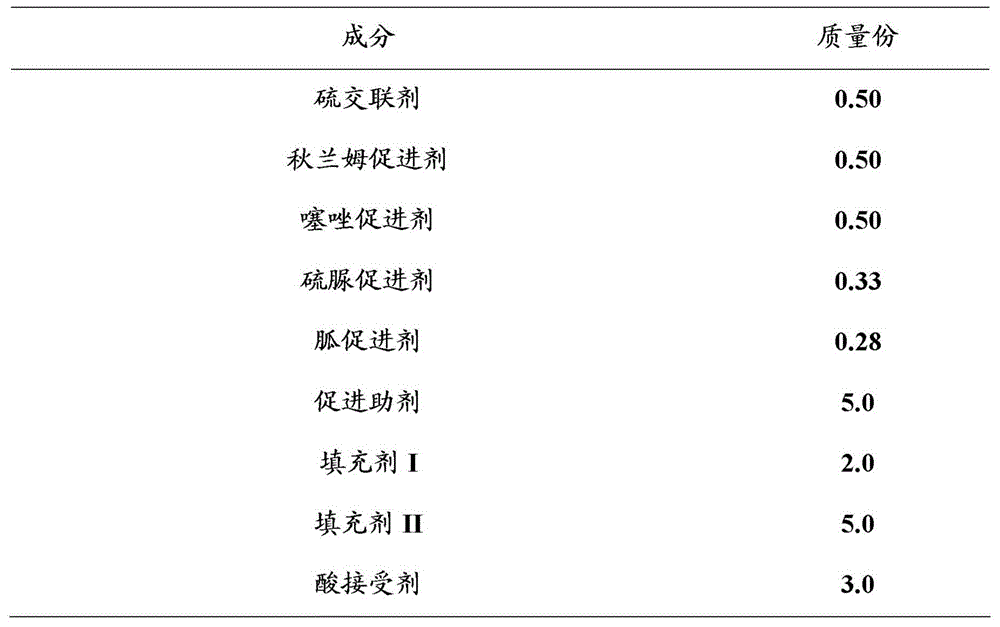

[0159] (Preparation of rubber composition)

[0160] By adding 50 parts by mass of GECO (purchased from DaisoCo., Ltd and EPION (registered trade name) 301 with a molar ratio of EO / EP / AGE=73 / 23 / 4), 20 parts by mass of CR (purchased from Showa Denko SHOPRENE (registered trade name) WRT) of Co., Ltd. and 30 parts by mass of NBR (low acrylonitrile content NBR JSRN250S purchased from JSR Co., Ltd. and having an acrylonitrile content of 20%) were blended to prepare a rubber component.

[0161] When 100 parts by mass of the rubber component were simply kneaded by a Banbury mixer, ingredients shown in Table 1 below except the crosslinking component were added to the rubber component and kneaded with the rubber component. Finally, a crosslinking component is added to the resulting mixture and further kneaded with the resulting mixture. Thus, a rubber composition was prepared.

[0162] Table 1

[0163]

[0164] The ingredients shown in Table 1 are as follows:

[0165] Sulfur cros...

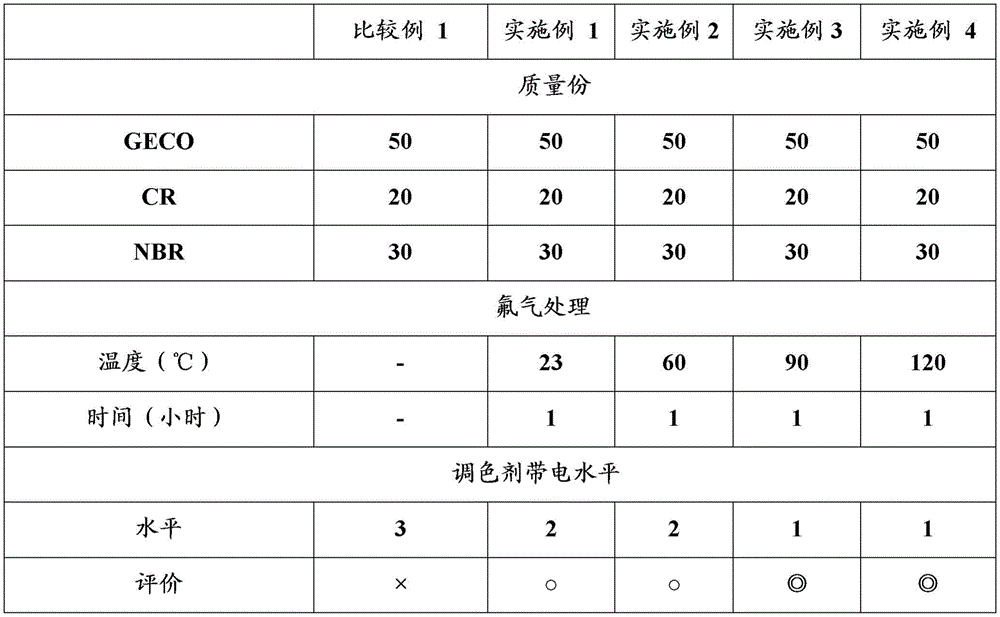

Embodiment 2

[0182] A semiconductive roller having a fluorinated film formed on its outer peripheral surface was produced in substantially the same manner as in Example 1, except that the fluorine gas treatment was performed at a treatment temperature of 60° C. and a treatment time of 1 hour.

Embodiment 3

[0184] A semiconductive roller having a fluorinated film formed on its outer peripheral surface was produced in substantially the same manner as in Example 1 except that the fluorine gas treatment was performed at a treatment temperature of 90° C. and a treatment time of 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com