Method for carrying out safety monitoring and early warning on kitchen work environment and system

A technology for safety monitoring and working environment, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as inability to change, single alarm level, inaccurate detection results, etc., to achieve intelligent monitoring and prevent safety accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

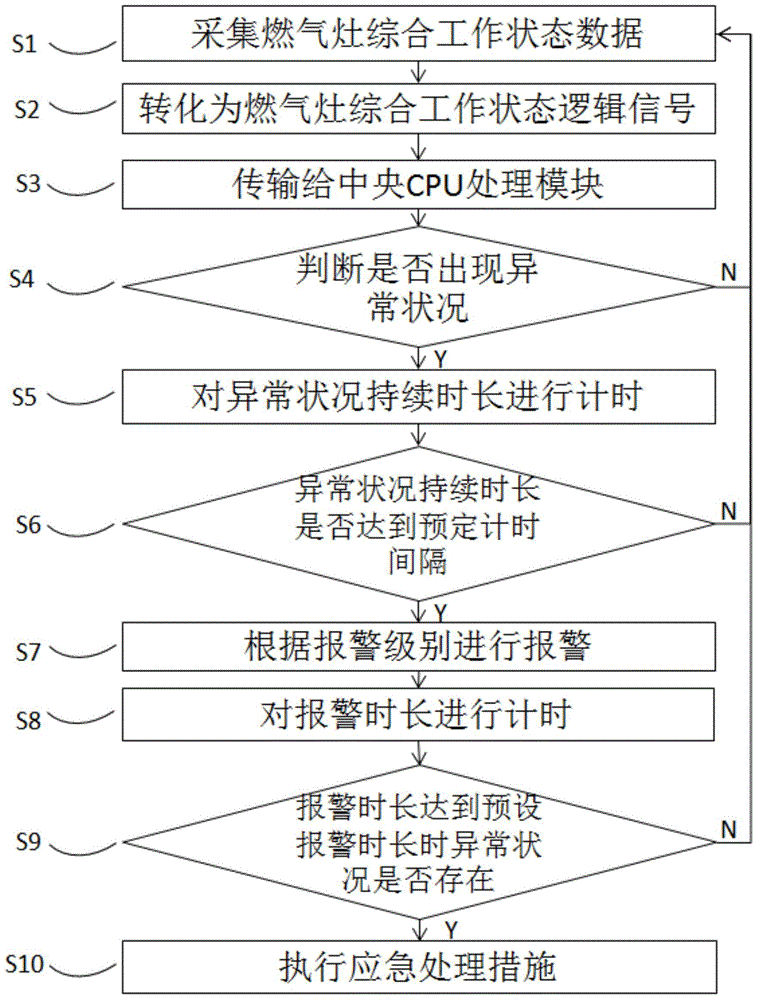

[0049] Such as figure 1 As shown, a method for safety monitoring and early warning of the kitchen working environment includes the following steps:

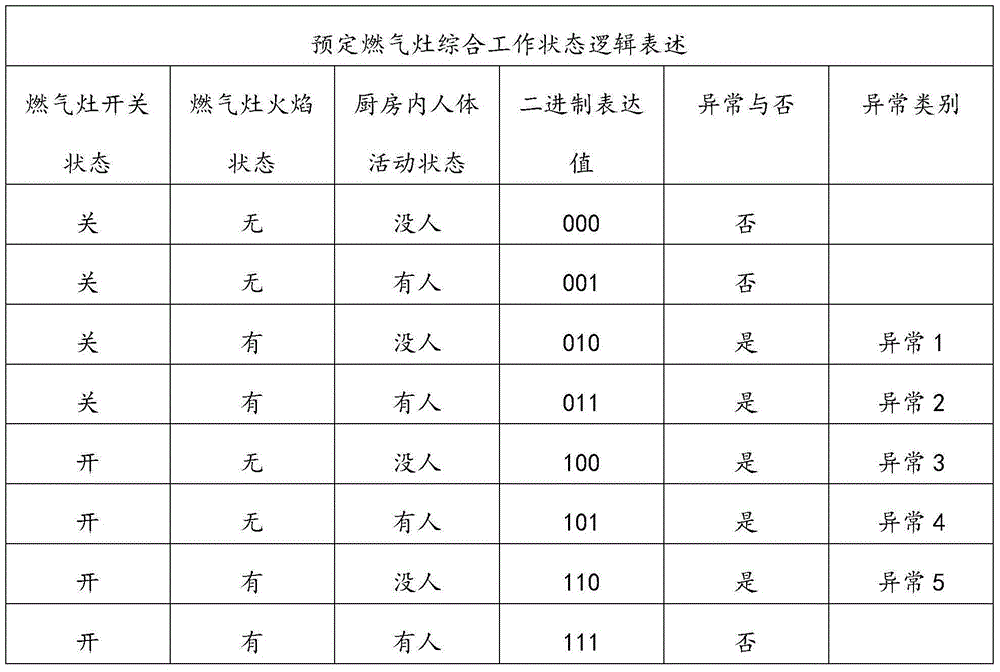

[0050] Step S1, collecting the comprehensive working state data of the gas stove; the comprehensive working state data of the gas stove includes the human body activity state data in the kitchen, the flame state data of the gas stove and the switch state data of the gas stove, the comprehensive working state data of the gas stove in the present invention It includes but is not limited to the above three status data, and more status data may be included as required. For example, it may also include collecting data on abnormal states of the human body, such as falls. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com