Flat cable of elevator and preparation method thereof

A technology for flat cables and elevators, applied in the field of elevator flat cables and their preparation, can solve the problems of low anti-aging performance and low tensile strength, achieve excellent electromagnetic shielding performance, reduce preparation costs, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

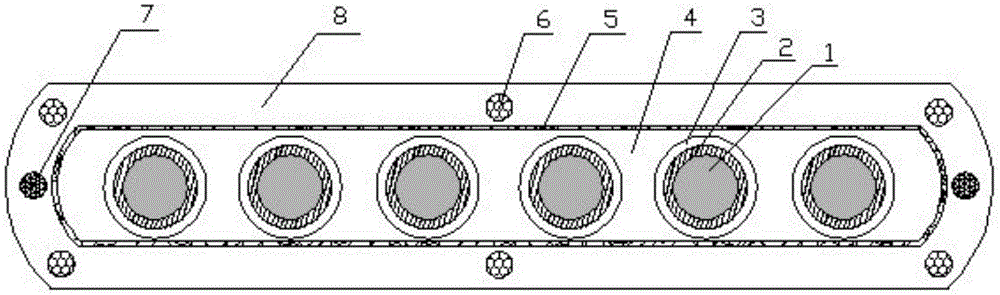

[0043] Such as figure 1 As shown, a flat cable for an elevator includes a metal guide core 1, an insulating layer 2, and a protective sheath layer 8 from the inside to the outside, wherein the insulating layer 2 and the protective sheath layer 8 are made of PVC material, and the outer layer of the insulating layer 2 It is also coated with a carbon fiber layer 3; there is also a filling layer 4 between the carbon fiber layer 3 and the protective sheath layer 8, and the filling layer 4 is polypropylene added with α-alumina. The carbon fiber layer 3 is soft carbon fiber.

[0044] In addition, there is a talcum powder layer 5 between the filling layer 4 and the protective sheath layer 8 .

[0045] The elevator flat cable also includes a tearing rope 6 and a reinforcing wire rope 7 , and the tearing rope 6 is located in the protective sheath layer 8 .

[0046] The structure of the elevator flat cable of the present invention contains a carbon fiber layer, which enhances the tensile...

Embodiment 2

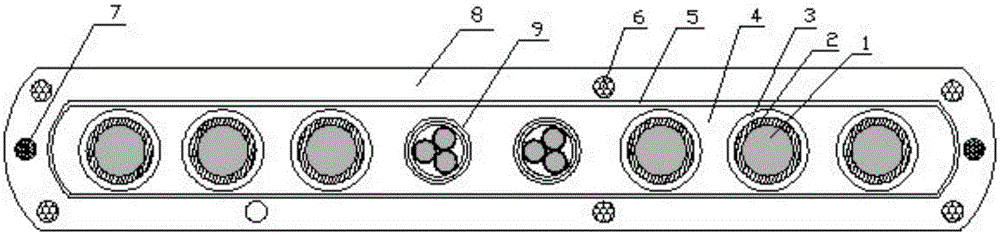

[0048] Such as figure 2 As shown, a flat cable for an elevator includes a metal guide core 1, an insulating layer 2, and a protective sheath layer 8 from the inside to the outside, wherein the insulating layer 2 and the protective sheath layer 8 are made of PVC material, and the outer layer of the insulating layer 2 It is also coated with a carbon fiber layer 3; there is also a filling layer 4 between the carbon fiber layer 3 and the protective sheath layer 8, and the filling layer 4 is a polypropylene layer added with α-alumina. The carbon fiber layer 3 is soft carbon fiber.

[0049] In addition, there is a talcum powder layer 5 between the filling layer 4 and the protective sheath layer 8 .

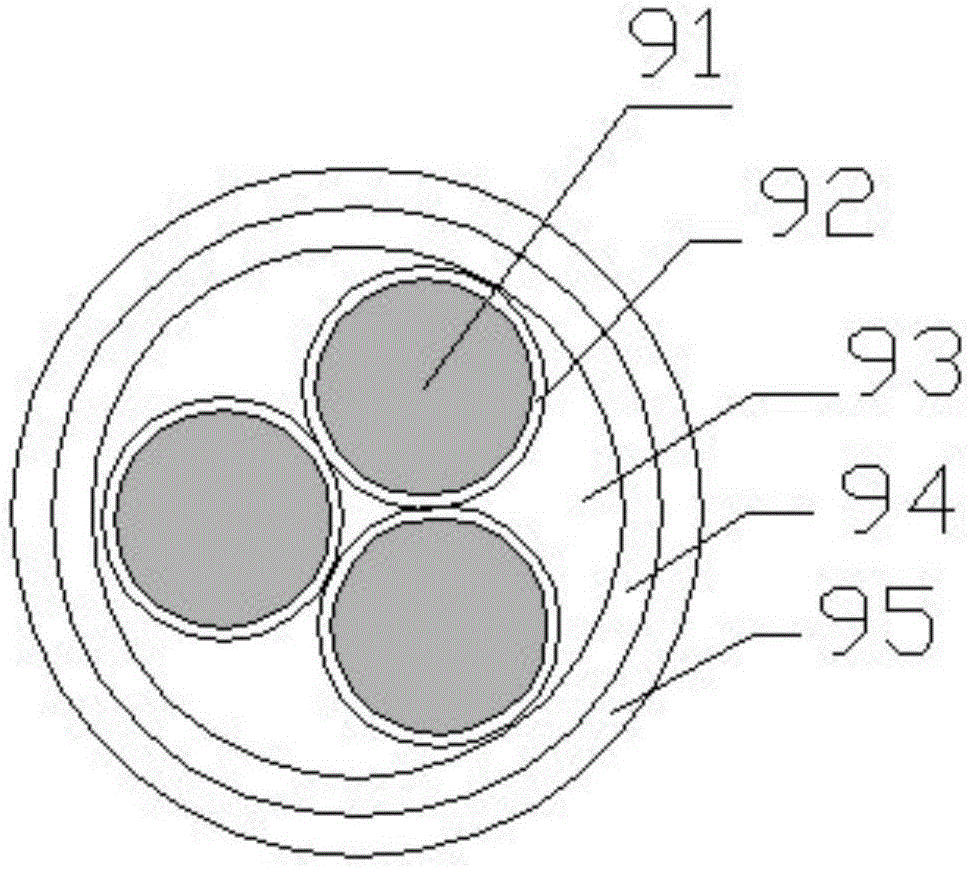

[0050] The elevator flat cable also includes a tearing rope 6 , a reinforcing steel wire rope 7 , and a communication cable 9 , and the tearing rope 6 is located in the protective sheath layer 8 . Such as image 3 As shown, the communication cable 9 includes an inner conductor 91, a...

Embodiment 3

[0053] refer to figure 1 , an elevator flat cable, which sequentially includes a metal guide core 1, an insulating layer 2, and a protective sheath layer 8 from the inside to the outside, wherein the insulating layer 2 and the protective sheath layer 8 are made of PVC material, and the outer part of the insulating layer 2 is also wrapped Covered with carbon fiber layer 3; there is also a filling layer 4 between the carbon fiber layer 3 and the protective sheath layer 8, and the filling layer 4 is a polypropylene layer added with α-alumina. The carbon fiber layer 3 is soft carbon fiber.

[0054] In addition, there is a graphite layer 5 between the filling layer 4 and the protective sheath layer 8 .

[0055] The structures and functions of other components are the same as in Embodiment 1.

[0056] The structure of the elevator flat cable of the present invention contains a graphite layer. On the one hand, it can offset the expansion effect between the cable inner core and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com