Fuse for protecting cells of battery pack of electric car

A technology of electric vehicles and single battery cells, which is applied to battery pack components, batteries, emergency protection devices, etc., can solve problems such as fire and explosion, and electric vehicle breakdowns, so as to prevent breakdowns, ensure normal driving, and avoid driving failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

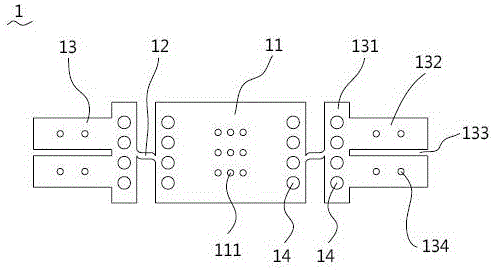

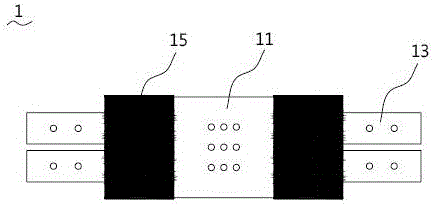

[0017] like figure 1 and figure 2 As shown, the fuse 1 for protecting the single cell of an electric vehicle battery pack provided in Embodiment 1 includes a busbar soldering piece 11, a pair of battery connection terminals 13 arranged symmetrically on the left and right sides of the busbar welding piece 11, connecting The fuse 12 of the busbar soldering piece 11 and the battery connection terminal 13 is respectively provided with a number of longitudinally arranged sealing holes 14 on the side where the busbar welding piece 11 and the battery connecting terminal 13 are connected to the fuse 12. The hole 14 is filled with plastic 15 by injection molding, and the plastic 15 plastically seals the busbar soldering piece 11, the fuse 12 and the battery connection terminal 13, and the fuse 12 is wrapped in the plastic 15, and the busbar welding piece 11 and the battery connection terminal 13 A plurality of busbar solder joints 111 and battery solder joints 134 for welding are cor...

Embodiment 2

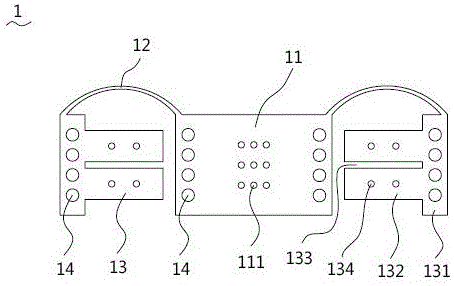

[0020] like image 3 and Figure 4 As shown, the electric vehicle battery cell protection fuse 1 provided by Embodiment 2 has the same structure as that of Embodiment 1, except that a pair of long fuses connected to the main body 131 on the battery connection terminal 13 The strip-shaped welding portion 132 extends toward the direction facing the busbar soldering piece 11. This structural design elongates the distance between the main body 131 of the battery connection terminal 13 and the busbar soldering piece 11, so that the connecting busbar soldering piece 11 The length of the fuse 12 connected to the battery connection terminal 13 also becomes longer. Since the fuse is extremely thin and easy to break, in order to protect the fuse, the fuse 12 connecting the bus bar soldering piece 11 and the battery connection terminal 13 is designed to be connected in an arc shape. When the vibration of the car causes the battery to vibrate, the arc fuse will not produce rigid force. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com