A kind of connection method of mgb2 superconducting wire rod

A technology of superconducting wire and connection method, which is applied in the direction of connection, connection contact material, line/collector parts, etc., can solve problems that have not yet been discovered, and achieve the effect of promoting the practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

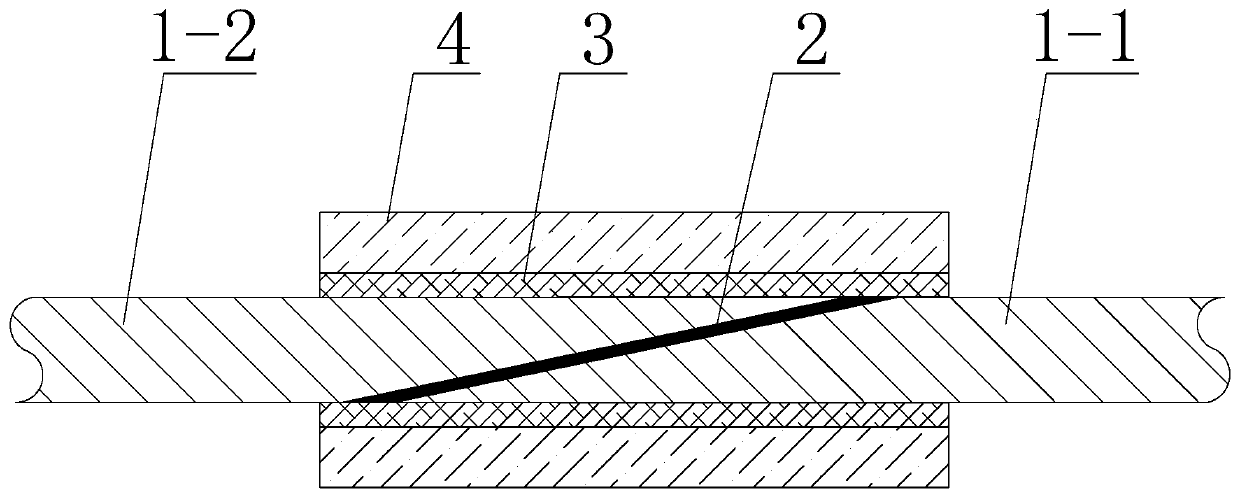

[0030] This example MgB 2 The connection method of superconducting wire includes the following steps:

[0031] Step 1. First, the first MgB 2 The terminal to be connected and the second MgB of superconducting wire 1-1 2 The ends to be connected of superconducting wires 1-2 are all wax-sealed to prevent MgB in the wires 2 The precursor powder is corroded by acid; then, the first MgB 2 Superconducting wire 1-1 and second MgB 2 The superconducting wires 1-2 are all placed in a nitric acid solution for pickling treatment to remove the outer Cu coating layer. The HNO in the nitric acid solution 3 With H 2 The molar ratio of O is 1:1.8; after that, the first MgB after pickling treatment 2 The end to be connected of superconducting wire 1-1 and the second MgB after pickling treatment 2 The ends of the superconducting wires 1-2 to be connected are all ground into a slope shape, and the slope angle (the angle between the horizontal plane and the inclined surface) is 5°;

[0032] Step 2. First...

Embodiment 2

[0038] This example MgB 2 The connection method of superconducting wire includes the following steps:

[0039] Step 1. First, the first MgB 2 The terminal to be connected and the second MgB of superconducting wire 1-1 2 The ends to be connected of superconducting wires 1-2 are all wax-sealed to prevent MgB in the wires 2 The precursor powder is corroded by acid; then, the first MgB 2 Superconducting wire 1-1 and second MgB 2 The superconducting wires 1-2 are all placed in a nitric acid solution for pickling treatment to remove the outer Cu coating layer. The HNO in the nitric acid solution 3 With H 2 The molar ratio of O is 1:1.6; after that, the first MgB after pickling treatment 2 The end to be connected of superconducting wire 1-1 and the second MgB after pickling treatment 2 The ends of superconducting wires 1-2 to be connected are all ground into a slope shape, and the slope angle (the angle between the horizontal plane and the inclined surface) is 10°;

[0040] Step 2. First, m...

Embodiment 3

[0046] This example MgB 2 The connection method of superconducting wire includes the following steps:

[0047] Step 1. First, the first MgB 2 The terminal to be connected and the second MgB of superconducting wire 1-1 2 The ends to be connected of superconducting wires 1-2 are all wax-sealed to prevent MgB in the wires 2 The precursor powder is corroded by acid; then, the first MgB 2 Superconducting wire 1-1 and second MgB 2 The superconducting wires 1-2 are all placed in a nitric acid solution for pickling treatment to remove the outer Cu coating layer. The HNO in the nitric acid solution 3 With H 2 The molar ratio of O is 1:2; after that, the first MgB after pickling treatment 2 The end to be connected of superconducting wire 1-1 and the second MgB after pickling treatment 2 The ends of the superconducting wires 1-2 to be connected are all ground into a slope shape, and the slope angle (the angle between the horizontal plane and the inclined surface) is 15°;

[0048] Step 2. First,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com