Connection method for MgB2 superconductive wire rods

A technology of superconducting wire rod and connection method, which is applied in the direction of connection, connection contact material, circuit/collector parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

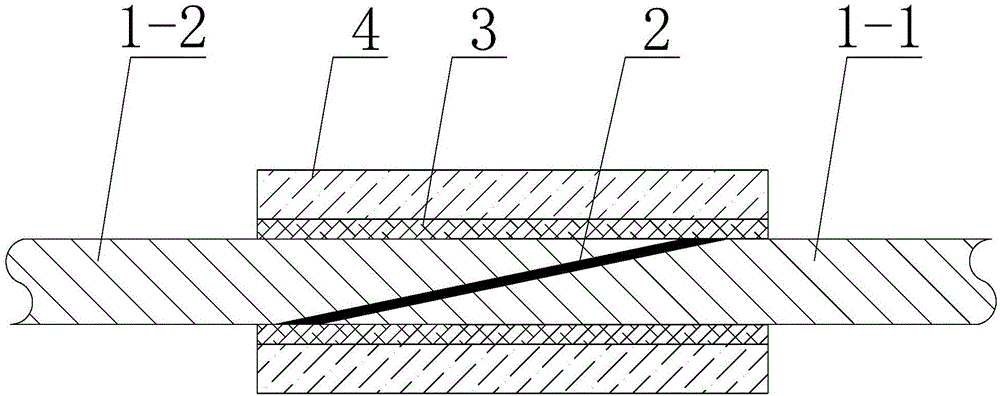

[0030] This example MgB 2 The connecting method of the superconducting wire comprises the following steps:

[0031] Step 1. First, the first MgB 2 The end to be connected of the superconducting wire 1-1 and the second MgB 2 The ends to be connected of the superconducting wires 1-2 are wax-sealed to prevent MgB in the wires 2 The precursor powder was corroded by acid solution; then, the first MgB 2 Superconducting wire 1-1 and the second MgB 2 The superconducting wires 1-2 are all placed in a nitric acid solution for pickling treatment to remove the outer Cu cladding layer, and the HNO in the nitric acid solution 3 with H 2 The molar ratio of O is 1:1.8; after that, the first MgB after pickling treatment 2 The end to be connected of the superconducting wire 1-1 and the second MgB after pickling treatment 2 The ends to be connected of the superconducting wires 1-2 are ground into a slope shape, and the slope angle (the angle between the horizontal plane and the inclined p...

Embodiment 2

[0038] This example MgB 2 The connecting method of the superconducting wire comprises the following steps:

[0039] Step 1. First, the first MgB 2 The end to be connected of the superconducting wire 1-1 and the second MgB 2 The ends to be connected of the superconducting wires 1-2 are wax-sealed to prevent MgB in the wires 2 The precursor powder was corroded by acid solution; then, the first MgB 2 Superconducting wire 1-1 and the second MgB 2 The superconducting wires 1-2 are all placed in a nitric acid solution for pickling treatment to remove the outer Cu cladding layer, and the HNO in the nitric acid solution 3 with H 2 The molar ratio of O is 1:1.6; after that, the first MgB after pickling treatment 2 The end to be connected of the superconducting wire 1-1 and the second MgB after pickling treatment 2 The ends to be connected of the superconducting wires 1-2 are ground into a slope shape, and the slope angle (the angle between the horizontal plane and the inclined p...

Embodiment 3

[0046] This example MgB 2 The connecting method of the superconducting wire comprises the following steps:

[0047] Step 1. First, the first MgB 2 The end to be connected of the superconducting wire 1-1 and the second MgB 2 The ends to be connected of the superconducting wires 1-2 are wax-sealed to prevent MgB in the wires 2 The precursor powder was corroded by acid solution; then, the first MgB 2 Superconducting wire 1-1 and the second MgB 2 The superconducting wires 1-2 are all placed in a nitric acid solution for pickling treatment to remove the outer Cu cladding layer, and the HNO in the nitric acid solution 3 with H 2 The molar ratio of O is 1:2; after that, the first MgB after pickling treatment 2 The end to be connected of the superconducting wire 1-1 and the second MgB after pickling treatment 2 The ends to be connected of the superconducting wires 1-2 are ground into a slope shape, and the slope angle (the angle between the horizontal plane and the inclined pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com