Bud seedling greening machine

A sprout and turntable technology, which is applied in the field of sprout production equipment, can solve the problems of large space occupation, high labor intensity, and low production efficiency, and achieve the effects of improving production efficiency, reducing labor intensity, and occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

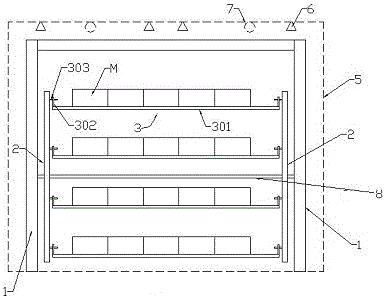

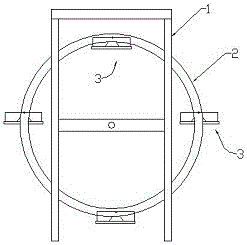

[0046] Examples such as figure 1 , figure 2 As shown, the sprout greening machine includes two vertical supports 1, and two coaxially arranged turntables 2 are rotatably connected between the two supports 1, and the two turntables 2 are connected by a rotating shaft 8 through transmission connection. The axis line is consistent with the axis line of the turntable 2, and several brackets 3 for placing seedling trays are rotatably connected between the two turntables 2.

[0047] The brackets 3 are evenly arranged along the circumferential direction of the turntable 2 .

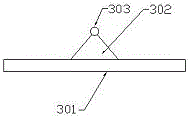

[0048] Such as image 3 As shown, the bracket 3 includes a rectangular supporting plate 301, the two ends of the supporting plate 301 are fixedly connected with the connecting frame 302, the connecting frame 302 is vertically arranged with the supporting plate 301, and the connecting frame 302 is fixedly connected with the connecting shaft 303.

[0049] The bracket 3 is rotationally connected with the turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com