Furfural steam slag separation and recovery device and recovery method thereof

A steam slag separation and recovery device technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as poor production environment in workshops, impact on residents' lives, and damage to employees' health, so as to improve operating environment conditions , Conducive to safe production, save the effect of forklift investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

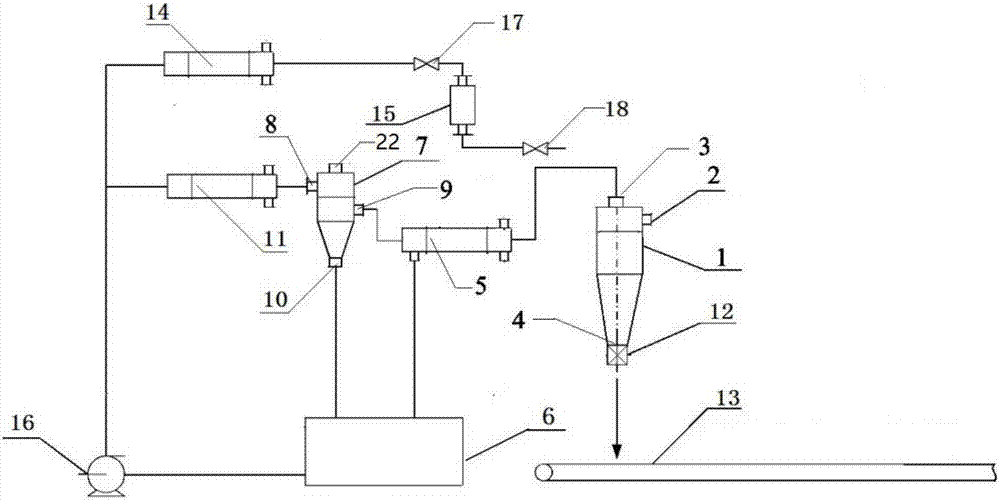

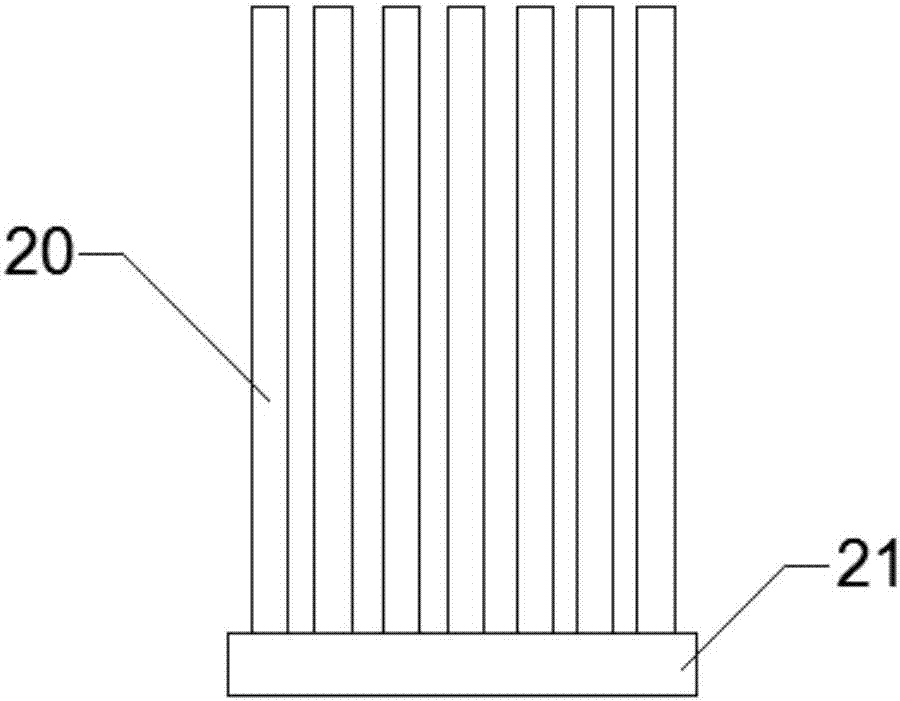

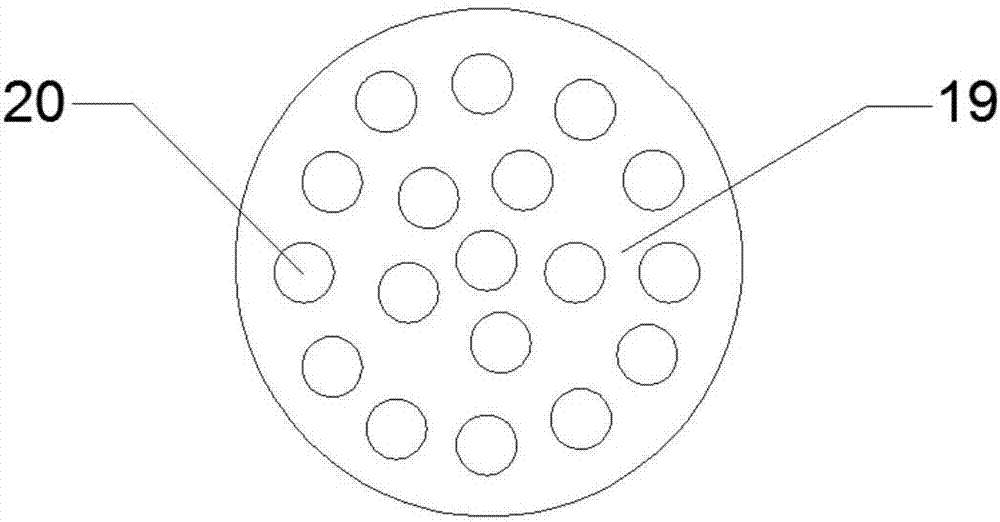

[0048] Such as Figure 1-3 As shown, the invention provides a kind of furfural steam slag separation and recovery device, comprising:

[0049] Gas slag separator 1, which has a feed port 2 for accessing furfural slag, and a first outlet 3 for waste gas after centrifugation and a second outlet 4 for waste slag; the waste slag can be separated from the waste gas by using the gas slag separator , the waste gas is discharged from the first outlet 3, and the waste residue is discharged from the second outlet 4;

[0050] The first condenser 5 has a first cold medium flow channel and a first heat medium flow channel, the inlet of the first heat medium flow channel communicates with the first outlet, and the first heat medium flow channel has two an outlet, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com