An all-in-one welding machine for the mouth and bottom of a stainless steel thermos cup and its working principle

A stainless steel, all-in-one technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low production efficiency, cost, and high personnel cost, improve production efficiency, improve product quality, and reduce machine usage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

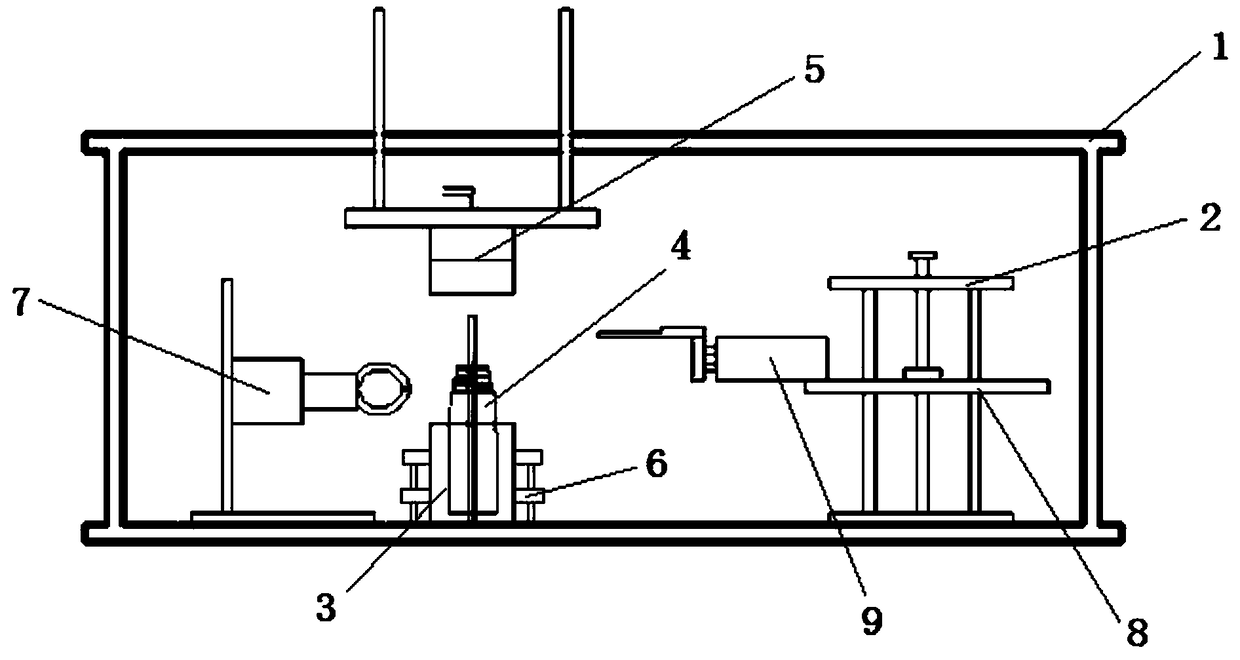

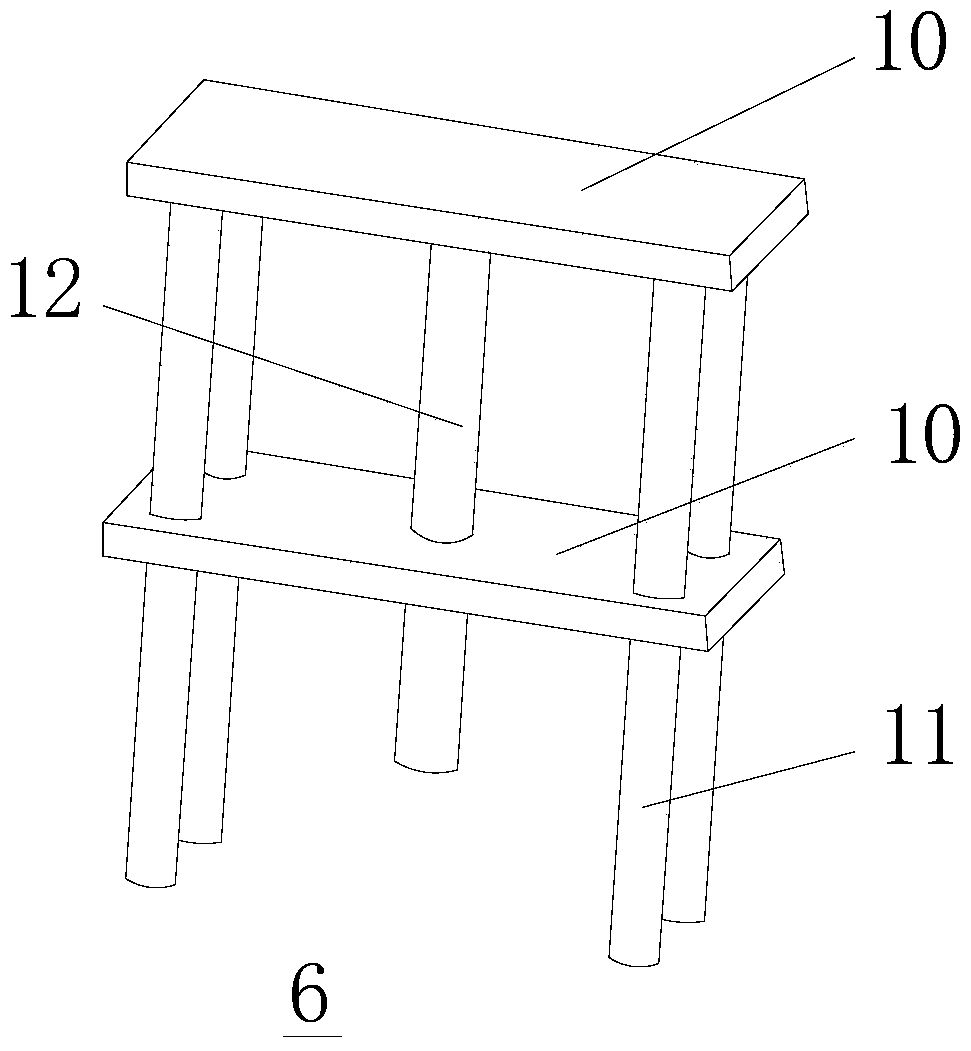

[0019] Please combine figure 1 and figure 2 As shown, a stainless steel insulation cup mouth and bottom welding integrated machine of the present invention includes an automatic feeding device 2 at the bottom of the outer tube, a suction cup device 5 at the bottom of the outer tube, a manipulator device 7 and a workpiece fixture 3, wherein the automatic feeding device 2 is fixed on the machine On one side of the table 1, the outer tube bottom suction cup device 5 is installed on the inner top of the machine table through the hydraulic pressurized cylinder, the workpiece fixture 3 is fixed under the outer tube bottom suction cup device 5, and the manipulator device 7 is fixed on the side of the workpiece fixture 3, and the workpiece fixture The rear of 3 is also equipped with automatic welding device 6.

[0020] On the basis of the above, the present invention also has the following implementation modes, please continue to refer to figure 1 and figure 2 as shown,

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com