High-speed air-exhausting and defoaming stirring machine

A high-speed mixer and mixer technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as affecting the fullness of the filling slurry, poor conveying effect, and wear of stirring rods, and eliminate flow interruptions. The risk of pipe blockage, the effect of increasing the fullness of the pipe and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

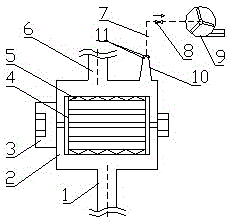

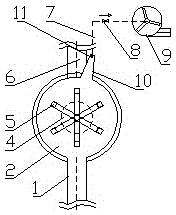

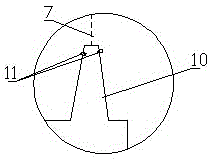

[0025] refer to figure 1 , figure 2 , image 3 , the present embodiment includes a mixer housing 2, a transmission part 3, the top of the mixer housing 2 is provided with a feed inlet 6, the bottom of the mixer housing 2 is provided with a discharge port 1, and the mixer housing 2 is provided with a stirring rod 5. The rod 5 is connected with the mixer housing 2 through the fixed frame 4, the transmission part 3 is connected with the stirring rod 5, and drives the stirring rod 5 to rotate; an exhaust fan 9 is also provided, and the exhaust fan 9 is connected with the mixer housing 2 through the exhaust pipe 7, The exhaust pipe 7 communicates with the inside of the mixer housing 2; the top of the mixer housing 2 is also provided with a gas collecting hood 10, the exhaust pipe 7 communicates with the gas collecting hood 10, and the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com