Panel fixing structure and partition and vehicle with the partition

A technology for fixing structures and panels, applied to vehicle parts, transportation and packaging, etc., can solve the problems of increased labor intensity, uneven panels, increased labor, etc., and achieve the effects of saving materials, high bonding strength, and reducing labor levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

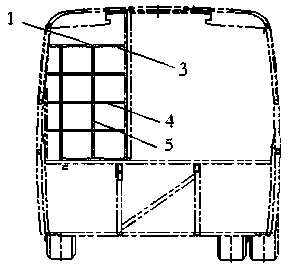

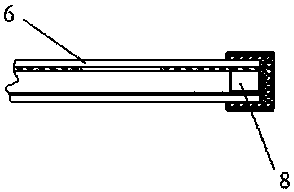

[0021] The present invention will be further described below in conjunction with accompanying drawing and embodiment, as figure 1 , 2 As shown, a vehicle of the present invention includes a partition, and the partition includes a panel fixing structure, and the panel fixing structure includes a skeleton 8 and a panel 6, and the panel 6 is bonded and fixed on the skeleton 8 through an adhesive layer, and the adhesive layer It includes positioning double-sided adhesive tape 3 for positioning and connecting skeleton 8 and panel 6 and fixed adhesive colloid 1 for fixedly connecting skeleton 8 and panel 6, and the adhesive layer is a network structure including a horizontal strip-shaped adhesive layer and a longitudinal strip-shaped adhesive layer. , each horizontal and vertical strip-shaped adhesive layer is a strip-shaped structure composed of positioning double-sided adhesive tape 3 and fixed adhesive colloid 1 at alternating intervals. This panel fixing structure quickly fixes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com