A film cutting and pulling method suitable for material packaging

A packaging film and material technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inconvenient packaging process, time-consuming and energy-consuming, and reduce packaging efficiency, so as to save time for debugging the position of the film cutting mechanism and save Pause time, the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

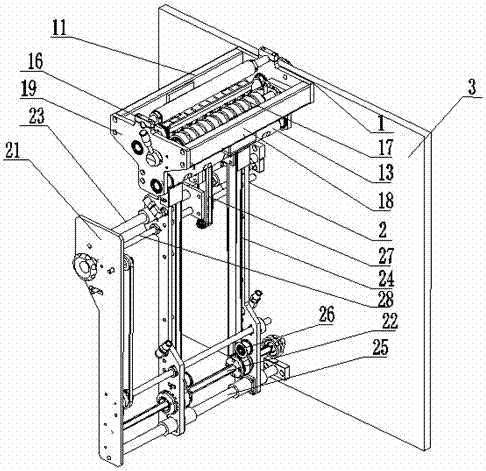

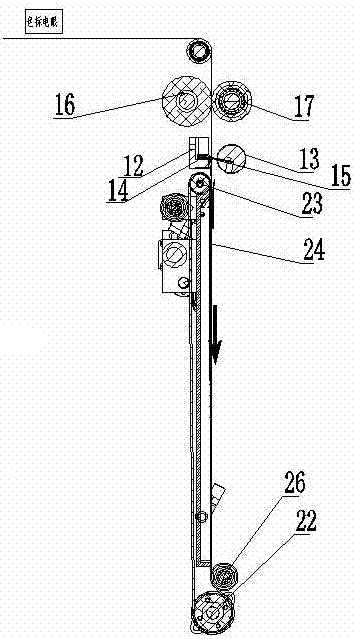

Image

Examples

Embodiment 1

[0037] As a preferred embodiment of the present invention, this embodiment discloses a film cutting and pulling method suitable for material packaging. This embodiment includes: the steps are as follows:

[0038] Conveying step: the packaging film is conveyed from the film unloading station to the

[0039] Cutting step: the tension-controlled packaging film is conveyed to the film cutting station, and the film cutting station cuts the packaging film during the packaging film conveying process, and conveys the cut packaging film to the

[0040] Film pulling step: the cut packaging film is transported to the film pulling station, and the film pulling station transports the cut packaging film to the set position for packaging.

[0041] The cutting step is carried out during the conveying process of the packaging film, which is quite different from the existing packaging process; controlling the tension of the packaging film can ensure that the packaging film is stretched during t...

Embodiment 2

[0043] As another preferred embodiment of the present invention, this embodiment discloses a film cutting and pulling method suitable for material packaging. This embodiment includes: the steps are as follows:

[0044] The packaging process of this embodiment is the same as that of Example 1, but there is a certain improvement in the detection of the set length of the conveying packaging film. The packaging process of this embodiment cuts the packaging film during the conveying process of the packaging film, saving At the same time, a color-coded electric eye detection mechanism is set between the packaging film from the film-releasing station to the film-cutting station. The color-coded electric eye detects the length of the conveyed packaging film. When the length is set, the film cutting station cuts the packaging film, cuts the packaging film into a packaging film of a set length, and then transports it to the film pulling station. The set length of the packaging film can ...

Embodiment 3

[0046] As another preferred embodiment of the present invention, this embodiment discloses a film cutting and pulling method suitable for material packaging. This embodiment is a further improvement made on the basis of Embodiment 2. Except for In addition to all the technical features in Embodiment 2, it also includes:

[0047] In the cutting step, the cutting of the packaging film by the film cutting station during the conveying process of the packaging film specifically refers to: the cutting station cuts the packaging film when the packaging film is conveyed through the cutting station and conveyed to a set length.

[0048] In the film pulling step, the film pulling station transports the cut packaging film to the set position and waits for packaging. Specifically, it means: when the cut packaging film is transported to the set position, the film pulling station stops, and the bag pushing mechanism pushes the material Push to the cut packaging film and push the material to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com